It’s been several weeks since I made the call for “shock digitalization” to urgently accelerate the German economy’s digital transformation. The case for this radical shift has only become more pressing.

Our Economy and Climate Minister, Robert Habeck, confirmed the other week what many of us feared: Germany’s economy is set to contract for the second year in a row. This follows an already weak performance in 2023, where we were the slowest-growing economy among both the eurozone’s largest peers and the G7, with a 0.3% decline in GDP.

And yet, despite the obvious need for a turnaround, digital transformation remains grossly undervalued as a solution—both in public discourse and across large portions of the economy.

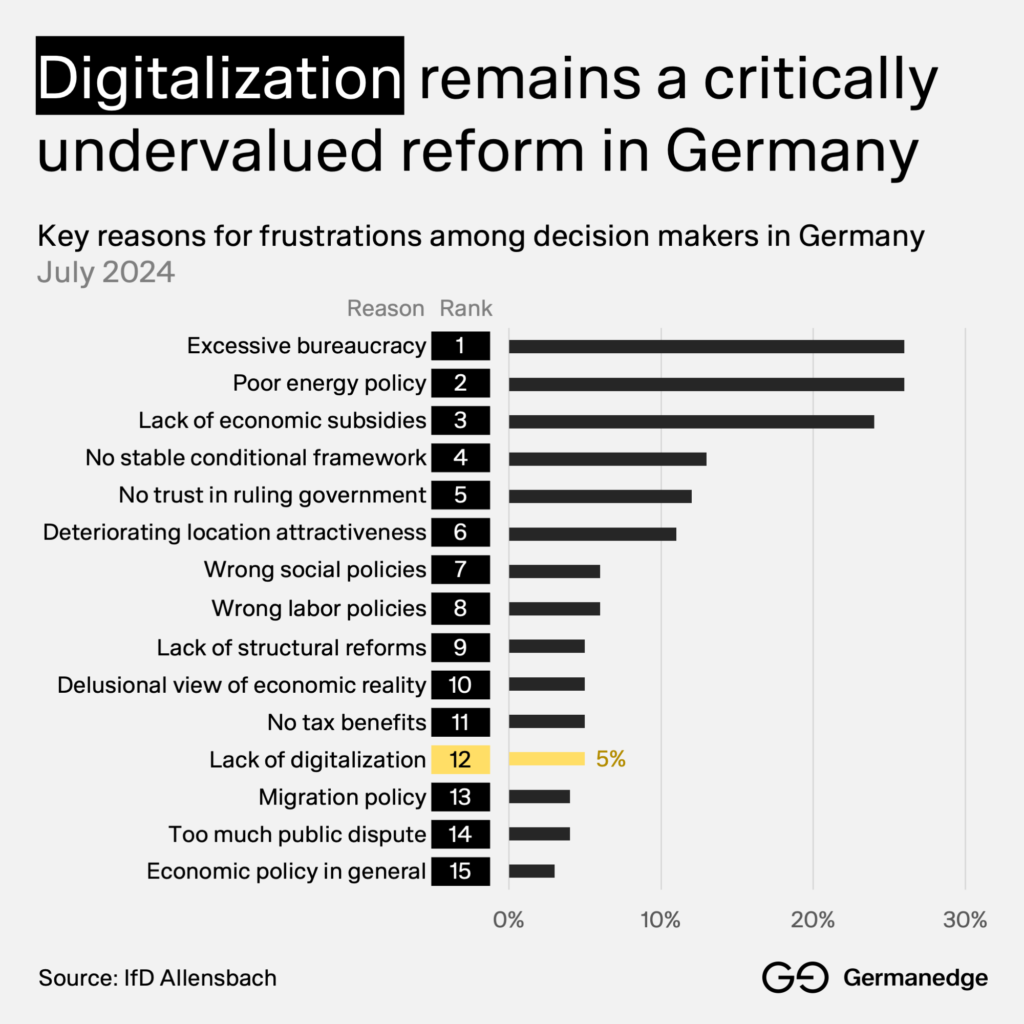

Case in point: According to the 2024 Allensbach Elite Panel survey, reported by Capital Magazin, which polled roughly 500 top economic decision-makers and executives in Germany, a mere 5% of respondents identified the lack of digital transformation as one of the major challenges impacting Germany’s economic competitiveness.

To put that into perspective, digital transformation ranked almost at the very bottom of the list, far below issues like excessive bureaucracy and energy policy.

In my view, this is a critical misconception and a dangerous flaw in how we’re thinking about revitalizing the German economy.

A direct call to our politicians and the current government: stop focusing solely on patchwork solutions and address the underlying issue. We need an economic strategy that hyper-focuses on innovation and digitalization at its core.

By continuing to deprioritize innovation—particularly the immense power of digitalization—we’re missing the key lever that could reignite our competitive edge.

The Digital Advantage: Outpacing Competitors Through Innovation

The evidence supporting the economic benefits of prioritizing digital innovation is undeniable. Companies that prioritize digitalization and have advanced in their digital transformation consistently outperform their competitors.

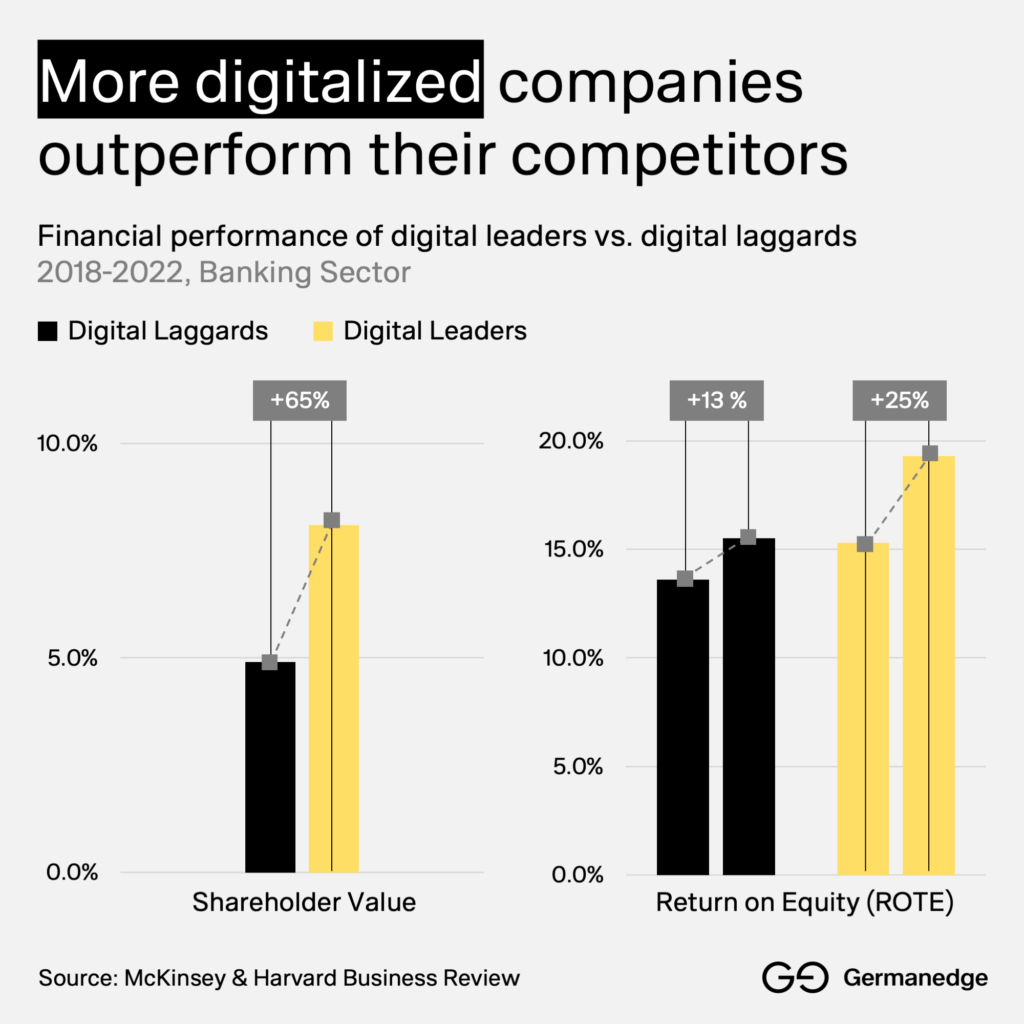

Take the banking sector, for example.

- Research from Harvard and McKinsey shows that between 2018 and 2022, digital leaders achieved an average annual total shareholder return of 8.1%, compared to 4.9% for digital laggards.

- These leaders also saw significantly better returns on pre-tax tangible equity (ROTE), increasing it from 15.5% to 19.3%, while laggards only saw a rise from 13.6% to 15.3%.

What’s driving this outperformance? Leaders excel at growing revenue and controlling expenses, showcasing the critical role of digital transformation in driving financial success.

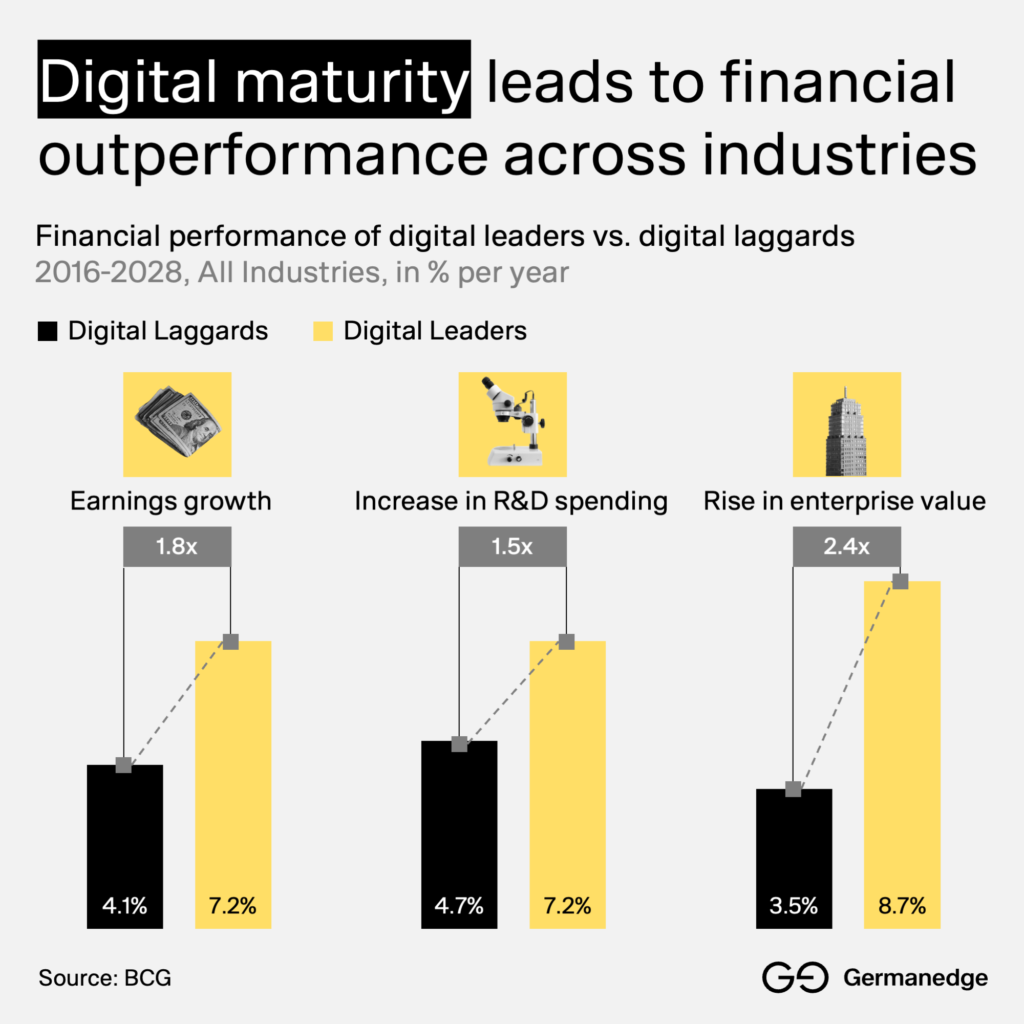

And this correlation isn’t just limited to banking. The same story plays out across other industries —whether B2B, B2C, products, or services.

- A study by BCG found that digital leaders across industries achieve earnings growth that is, on average, 1.8 times higher than digital laggards.

- Moreover, these leaders see more than double the growth in total enterprise value.

Why? Because digital technologies unlock productivity improvements, deliver better customer experiences, and create new avenues for growth and business model innovation.

This holds especially true in the industrial and manufacturing sectors. Academic research further strengthens this point, showing that the financial outperformance remains significant, even after accounting for the high costs associated with the digital transformation of factories. The study, which analyzed panel data from 2010 to 2020 across 2,254 manufacturing companies, found that the intensity of digital transformation is positively correlated with process-based operating performance.

Despite these compelling statistics, it’s disheartening to witness how little weight digital transformation holds in the collective German mindset when it comes to driving growth.

We must recognize that shock digitalization is not just a recommendation—it’s an immediate necessity to get our economy back on track.

To revive our economy and regain our competitive edge, we must act now!

The Case for Industrial Shock Digitalization

While the benefits of digital transformation are clear across various sectors, the discussion becomes especially critical when we focus on Germany’s industrial base — long considered the bedrock of our economy.

- For decades, Germany’s robust industrial sector, accounting for about a quarter of our GDP, has been the driving force behind our economic prosperity.

- This strength has been further strengthened by our small and medium-sized enterprises (SMEs), many of which are family-owned and are often referred to as the backbone of the German economy.

Unfortunately, this industrial legacy comes with a significant challenge: many of these businesses are deeply rooted in tradition, often cautious when it comes to adopting change.

This mindset extends beyond our traditional industrial sector. Across both the public and private spheres, Germany has developed a strong culture of frugality and risk aversion, particularly when it comes to spending on innovation. In both sectors, the focus has been on cost control rather than bold investments in the future, especially in areas like (digital) infrastructure and cutting-edge technology.

Couple this characteristic with our industrial heritage, and what you get is a recipe for economic stagnation. Risk avoidance has left us stuck in a cycle of incremental changes when what we need is a complete overhaul.

This is especially disheartening given that Germany has historically been one of the most progressive and forward-thinking nations in the world. As @Scott Galloway, professor of Marketing at NYU Stern School of Business, recently highlighted on his Prof G podcast, Germany has long held a position of global leadership in academia, science, industrial innovation, and economic strength—setting the pace for the rest of the world to follow.

His comment offers a valuable outside-in perspective, showing that it’s not just us Germans recognizing the role we’ve played in shaping the global economy for over 200 years. While our country was responsible for one of the darkest chapters in human history—a tragedy that must never be forgotten—our legacy of pioneering (hardware) technology and shaping industries is something we must build upon moving forward. Our undeniable track record of driving societal progress and shaping industries should be the legacy we return to.

The question is: how do we unlock this legacy once again and drive the next wave of industrial leadership?

The answer is simple: we need a bold Industrial Strategy that places shock digitalization at its very core.

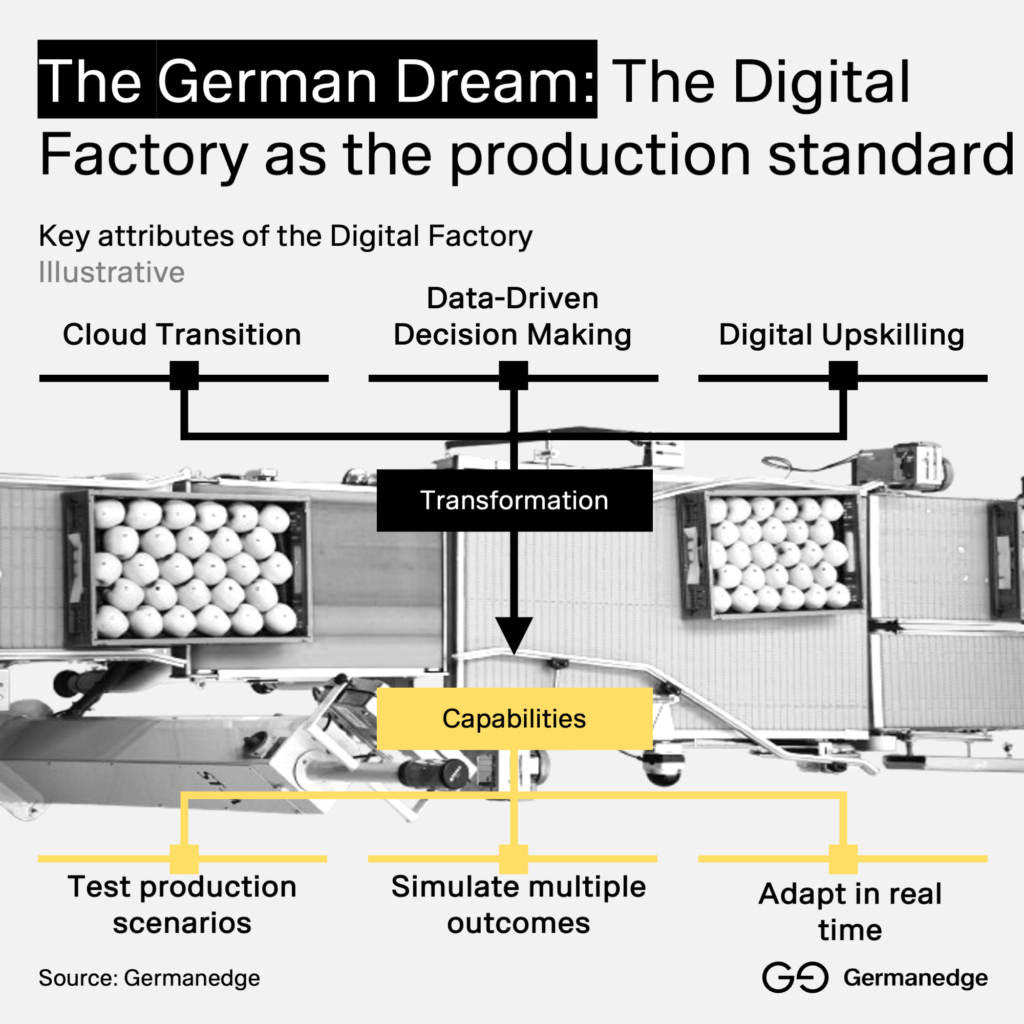

We must stop relying on incremental change and start envisioning the Digital Factory as our North Star for the industrial sector.

The Digital Factory represents more than just automation or isolated digital upgrades—it’s a complete rethinking of how we produce, innovate, and compete globally. It means fully integrating advanced technologies like AI, IoT, cloud computing, and robotics into every facet of production and supply chains.

It’s about moving from traditional, analog processes to interconnected, data-driven ecosystems.

In this digital factory of the future, the speed of innovation, production agility, and adaptability to market shifts will define success.

Blueprint of the Digital Factory

To pull off the vision of a fully digitalized industrial base, organizations must embrace immediate digital innovation at every level of their operations. This isn’t a one-time investment—it’s a commitment to a new way of thinking and working. It requires a holistic set of capabilities that span from leadership to production teams, all focused on rapid iteration and technological adaptation.

The effort required is significant, but so is the reward. And that reward doesn’t lie 18 months into the future—it’s something we can start realizing right now.

The Digital Factory means creating an agile, adaptable ecosystem where innovation is a constant process.

A true Digital Factory allows companies to:

- Test different production scenarios quickly and cost-effectively.

- Simulate various market conditions and customer demands.

- Explore alternative production paths with real-time data and immediate feedback.

Imagine being able to shift gears on production overnight based on current market changes, or test a new product idea and have it in MVP production within days. This adaptability is becoming a necessity in today’s fast-moving industrial landscape.

And this is exactly where we at Germanedge come into play.

Germanedge: Making the Digital Factory a Reality

At Germanedge, we are proud to be at the forefront of this industrial transformation. Our “Digital Factory as a Service” offering is designed to make this vision a reality for any industrial player, no matter their size or maturity level.

What does this mean in practice?

- Our Digital Factory lives in the cloud, ensuring it’s scalable, cost-efficient, and always up-to-date with the latest technological advancements.

- Our manufacturing software solutions enable companies to quickly test, iterate, deploy, and scale digital solutions. This agility helps businesses stay competitive by constantly refining their production methods in real-time.

But beyond agility and cloud capabilities, our Digital Factory offering is powered by a suite of specific, future-proof technologies that bring the entire production lifecycle into the digital age.

For a complete overview of all the features our Digital Factory offers, read the articel about it.

With these solutions, we empower our customers to leverage cutting-edge technology through our best-in-class, all-in-one MES and SCADA applications without the burden of managing complex IT systems themselves.

In essence, the Digital Factory is no longer a distant vision—it’s a present-day reality. And we at Germanedge are here to lead this charge.