Germany prides itself on its engineering prowess, its high-quality products, and its industrial heritage. But in an era of unstoppable digital transformation, we are at risk of being left behind. As Andreessen Horowitz famously announced over a decade ago, software is eating the world – and Germany is struggling to keep pace.

Our factories, once the beating heart of our economy, are woefully out of date compared to our international counterparts. Discussions around digitalization and Industry 4.0 have been ongoing for years, yet many German industrial firms lag far behind when it comes to implementing the digital strategies that are crucial for their survival in today’s market.

The concern is not just that we are trailing behind, but that we seem blissfully unaware of the pace at which our counterparts, particularly in the U.S. and China, have advanced. Scenarios of Germany’s „de-industrialization“ are becoming louder and louder, and while there may be multiple factors at play, our digital blindness is a significant driving force.

This digital blindness is a significant liability for a nation with a proud industrial history and a reputation for precision and quality.

In this article, I won’t shy away from confronting this uncomfortable truth that too many German business leaders and politicians still ignore. Instead, I’ll provide a handful of hard data points that lay bare the stark reality: When it comes to digital readiness, the German industry is alarmingly underprepared.

Welcome to the sobering reality of Germany’s Digital Lag: An Uncomfortable Reality Check.

The Decline of Germany’s Industrial Attractiveness

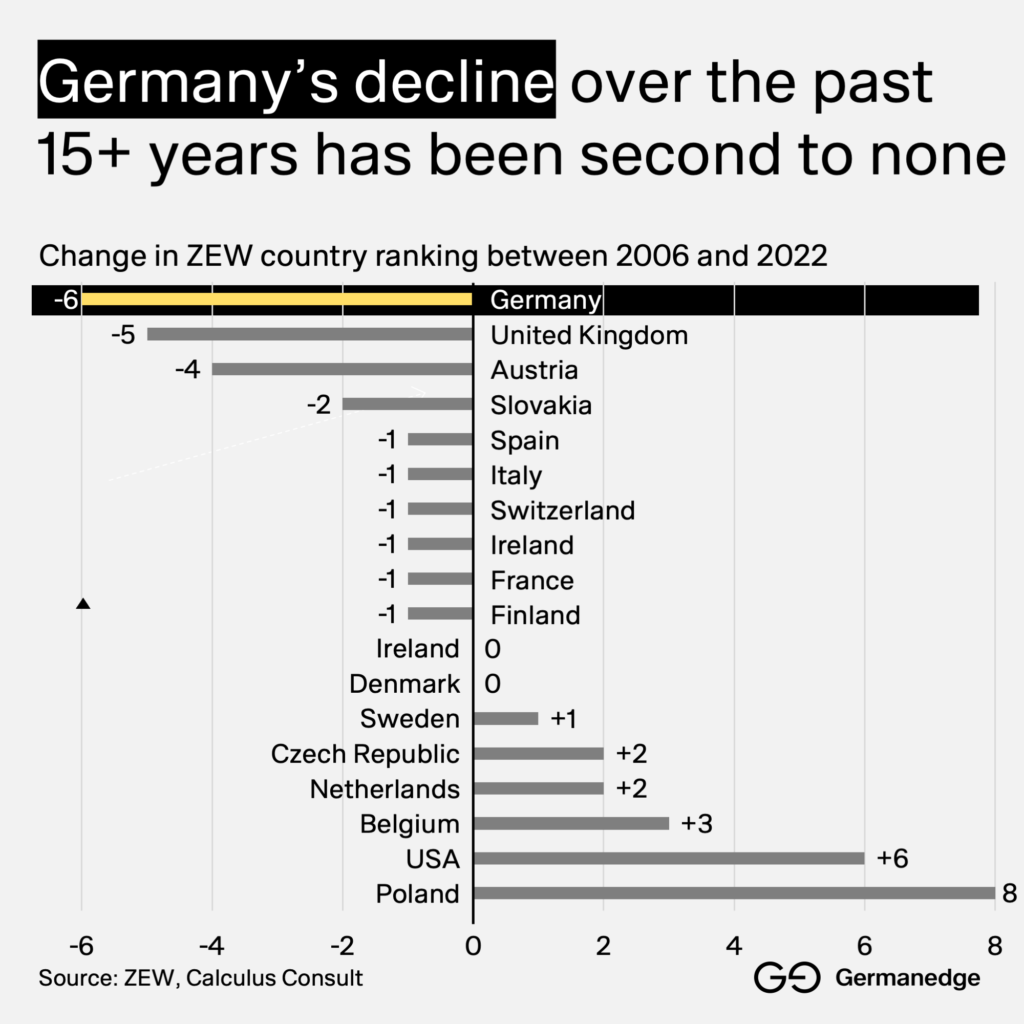

Once hailed as the world’s leading industrial nation, Germany’s reputation has been tarnished in recent years. According to the 2022 rankings by the Economic Research Institute ZEW, Germany sits alarmingly low on the 18th place among the world’s 21 leading industrial economies – surpassed by the likes of Ireland, Belgium, and Austria, and only outperforming Hungary, Spain, and Italy.

What led to this dramatic decline?

The study cites numerous culprits: surging energy costs, persistent labor shortages, high taxes, and a complex bureaucracy. But one factor stands out like a sore thumb – the sluggish pace of innovation in Germany.

What’s even more disturbing is how rapidly Germany’s position has eroded.

Over the past 15 years, no other nation in the ZEW’s ranking has lost more ground than Germany. Observe the downward trend for yourself:

When Industry 4.0 first began making waves in 2006, Germany was among the leaders in charge. But as the chart reveals, we’ve been slipping down the ranks with alarming consistency.

These findings are supported by other international studies as well.

- The Digital Riser Report, which compares the digital competitiveness of 137 countries worldwide, ranks Germany as the second lowest among the G7 nations and a dismal 17th among the G20. The report pulls no punches, stating that “Germany dropped enormously in terms of its relative competitive position.”

- In the 2022 IMD World Digital Competitiveness Ranking – an index evaluating the readiness of 63 economies to embrace and leverage digital technologies – Germany finds itself in the lower third for several crucial variables. It ranks an abysmal 52nd for technological skills and 40th for the development and application of digital technologies.

Taken together, these reports paint a stark picture of Germany’s ongoing struggle to stay competitive in the digital age.

The question is, can we arrest this decline before it’s too late?

Let’s delve deeper into the data to understand the root of the problem.

How Germany Overlooked the Fourth Industrial Revolution

Our current situation begs the question: How did Germany, an industrial powerhouse, lose its footing?

The answer lies in our reaction (or lack thereof) to the digital revolution.

We have, for the most part, been passive spectators as Industry 4.0 swept across the globe.

For far too long, we perceived technology primarily as a tool for optimizing production and reducing costs, rather than embracing it as a radical agent to transform our entire production and business processes. This narrow perspective had us focusing on incremental enhancements, while others were leapfrogging ahead.

As CEO of Germanedge, I’ve witnessed this phenomenon firsthand. German firms, many of which I’ve had the pleasure to work with, have historically perceived technology primarily as a tool for optimizing production and reducing costs. While they sought incremental efficiency gains, they often missed the bigger picture. In stark contrast, my interactions with American firms have shown a more holistic view of Industry 4.0. For them, technology is a transformative force capable of reshaping entire production and business processes.

Take the example of companies that promptly recognized the promise of the fourth industrial revolution and used it as a catalyst for change. A McKinsey report illustrates that these early adopters have not only become nimbler, and more efficient, but they have also elevated the quality of their output, thanks to technology-driven automation. As a result, this proactive approach to Industry 4.0 has rendered these countries more appealing to clients.

Consider Amazon, a company that has achieved unprecedented productivity levels through robotics and automation, establishing itself as a beacon of digital excellence. The rapid advancements at Amazon’s factories, which I discussed in a previous post, exemplify what’s possible when digital technologies are thoroughly embedded into operational frameworks.

Let’s pivot back to Germany. Despite being Europe’s largest economy, we’re lagging in digital readiness. The Digital Economy and Society Index (DESI), which measures digital performance and progress in EU countries, paints a sobering picture.

Germany lags behind the EU average on three out of four key indicators, including the crucial area of digital technology integration.

Our prospects for a swift digital turnaround are bleak.

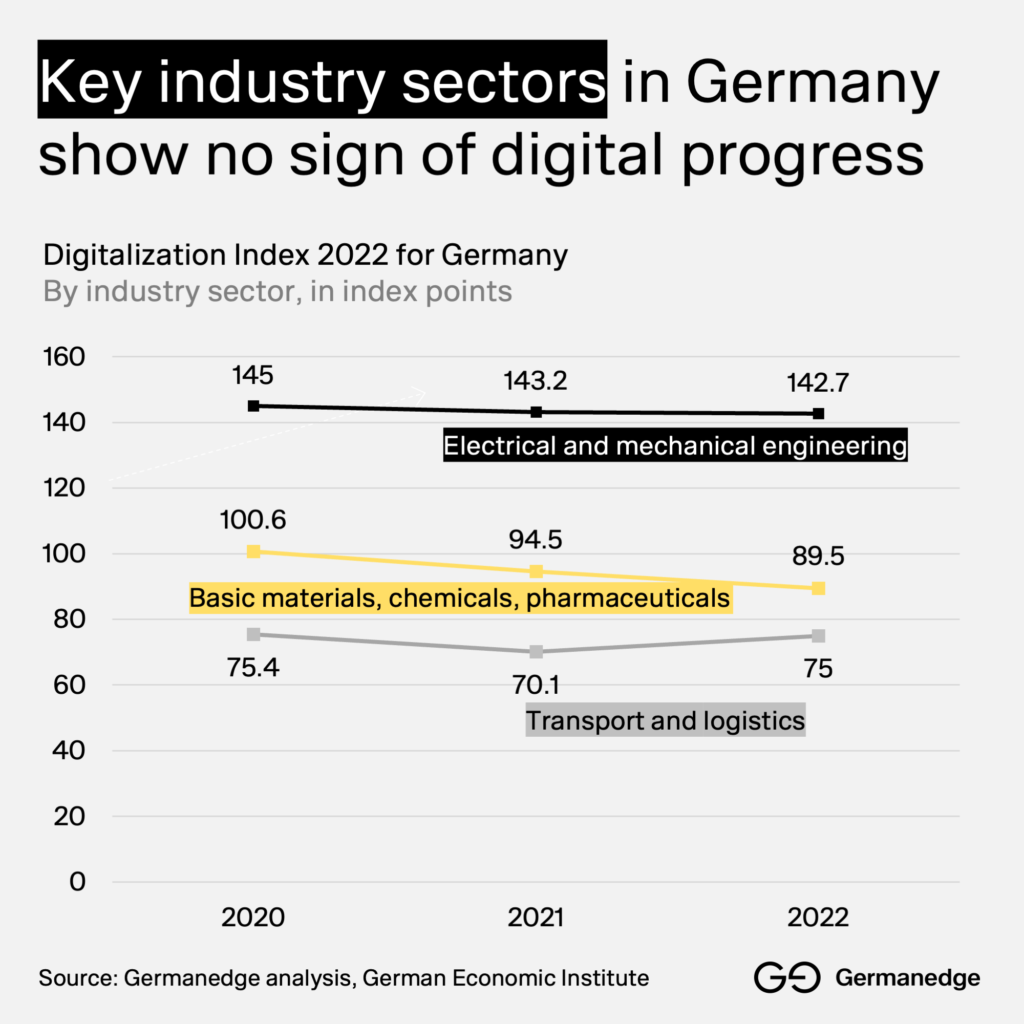

A recent report by the German Economic Institute highlights an alarming stagnation in digital progress across the ten major industry sectors over the past three years. The report ominously notes, „There are no major shifts in the digitalisation structure of the (German) industries in 2022.“

Adding insult to injury, three critical industrial sectors – Engineering, Logistics and Basic Materials, the latter includes chemicals and pharmaceuticals – have shown no signs of digital advancement over the previous three years.

The message from all of this is crystal clear: we’re falling short, and we’re not catching up fast enough.

The question remains: what are we going to do about it?

A Call to Acknowledge Our Shortcomings

To address a problem, first, we must accept that we have one.

Sadly, Germany’s industrial sector seems to be hampered by its legacy of arrogance.

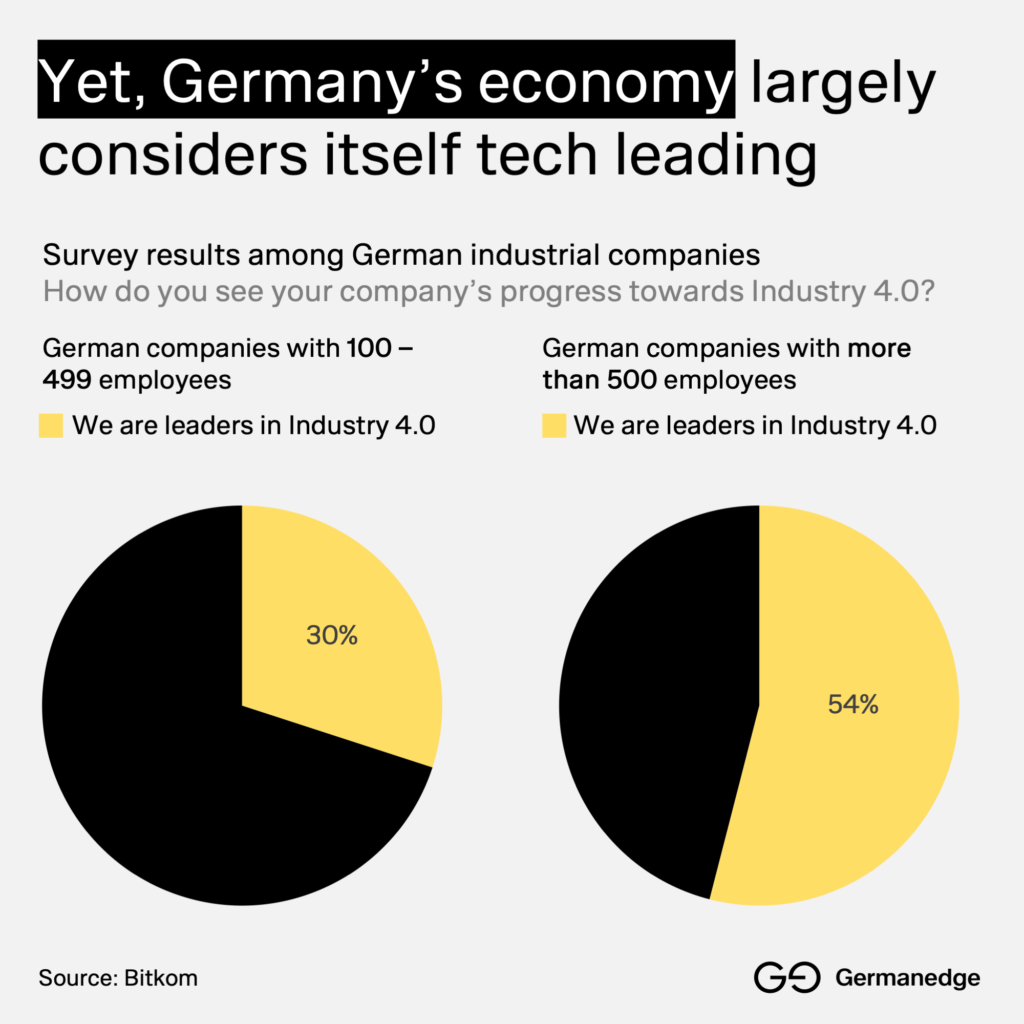

A significant portion of our companies still consider themselves frontrunners in the realm of Industry 4.0.

In the 2022 Bitkom Industry 4.0 report, nearly one-third of small and medium-sized industrial companies in Germany claimed to be leading the pack in terms of Industry 4.0. This self-assuredness skyrockets to over half when we consider enterprises with more than 500 employees.

This self-perception sharply contrasts with the hard facts on the ground.

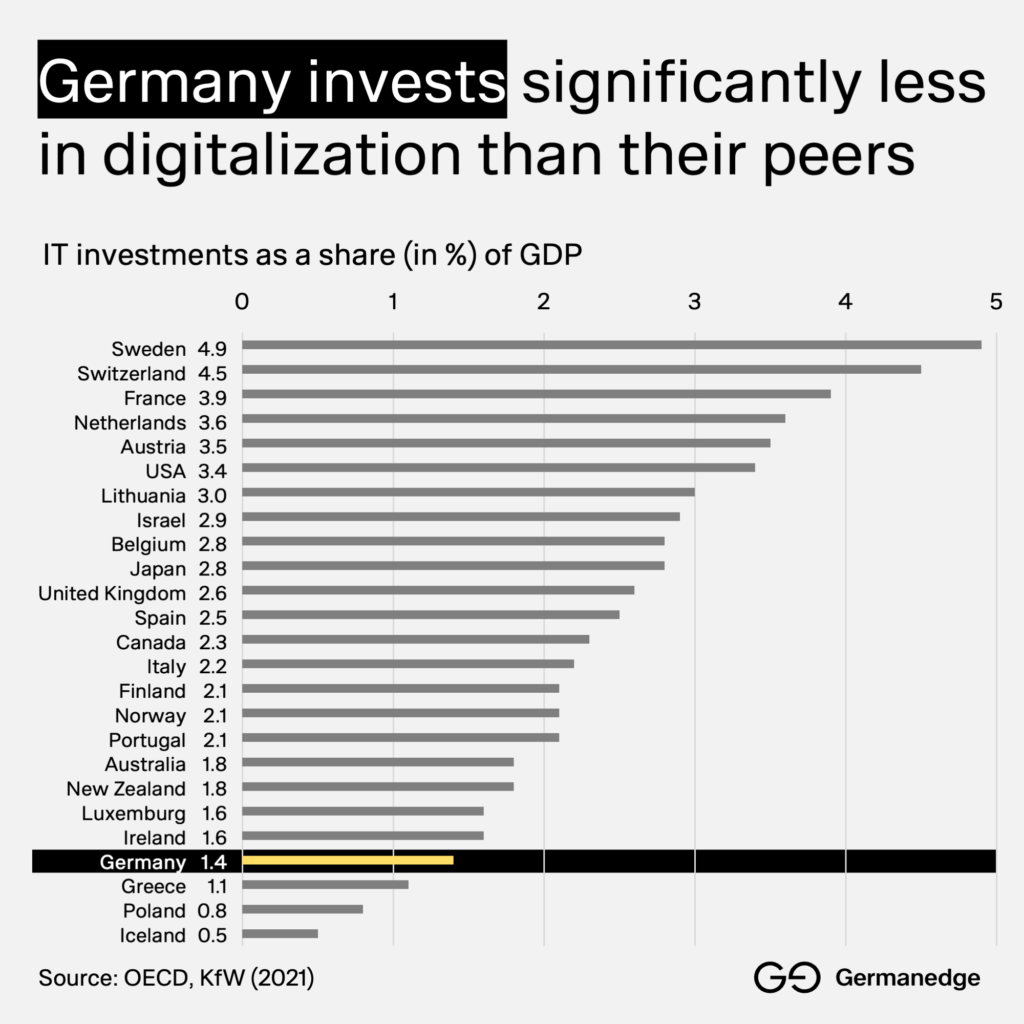

Our IT investments – a solid indicator of our commitment to digital transformation – are noticeably sparse.

According to research by the KfW, when it comes to investing in IT, Germany is lagging behind the vast majority of leading economies.

In simpler terms, we’re failing to put our money where our mouth is.

This discrepancy between our self-image and our actual digital readiness should serve as a wake-up call.

It’s time to take a critical look at where we stand and chart a course towards the digital future we aspire to.

Act Now: Secure Germany’s Future in the Fourth Industrial Revolution

Digitalization is no longer an optional trend; it is the bedrock upon which the future global economy will rest. This transformational wave is shaping every sector, including the once-mechanized world of industry, driving a paradigm shift known as Industry 4.0.

This shift transcends manufacturing, altering the industrial landscape in ways unrecognizable from the analog systems of yesteryear.

Countries like the U.S. and China have wholeheartedly embraced this shift, leveraging it to enhance their industrial capabilities, secure a competitive edge, and future-proof their economies.

Germany, a nation that once led the way in industrialization with pioneering companies like ThyssenKrupp and Volkswagen, can no longer afford to lag. If we aspire to reclaim our leadership role in the industrial space, the time to act was yesterday.

The German approach towards Industry 4.0 so far has largely revolved around precision and optimization. However, to truly excel in the new era of the digital industrial revolution, we need more. We need an entrepreneurial spirit, a readiness to take risks, swift reactions, unwavering dedication to the customer, and, most importantly, a willingness to change.

These attributes long characterized the German economy and society during the first industrial revolution, but somewhere along the way, they got lost.

At Germanedge, we are committed to reigniting this spirit.

In alignment with our mantra of „creating the perfect flow,“ we offer innovative software solutions designed to enable companies to manufacture more intelligently, flexibly, and sustainably. But our offerings extend beyond just tools; we provide the vision necessary to ensure maximum robustness at all times and every point in your production process.

With Germanedge, you’re not merely upgrading your current capabilities; you’re future-proofing your operations. We assist you in devising the ideal blueprint for a digital factory, eliminating unnecessary detours and dead ends on your journey towards Industry 4.0.

Together, we can secure Germany’s place in the Fourth Industrial Revolution by fostering the mindset shift needed for this new digital age.