A recall is the worst case scenario for any company. It causes enormous costs and makes negative headlines. Product recalls are not uncommon. According to statistics, there are around 300 product recalls in Germany alone and over 2,000 Rapex notifications from European member states every year. Reworking in production results in costs that can quickly run into the tens of millions. Reducing these scenarios by just 1% means enormous cost savings.

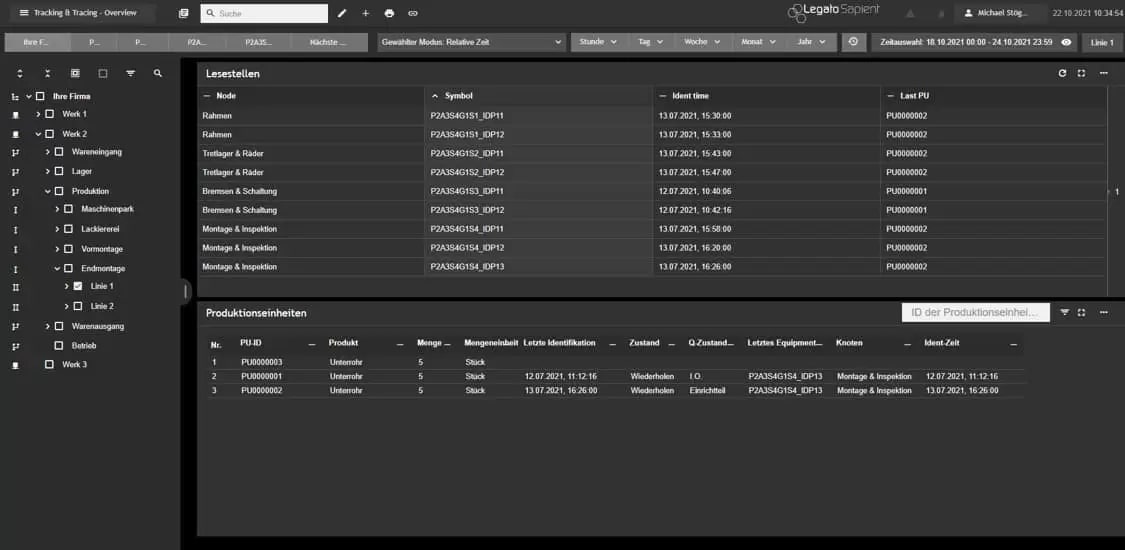

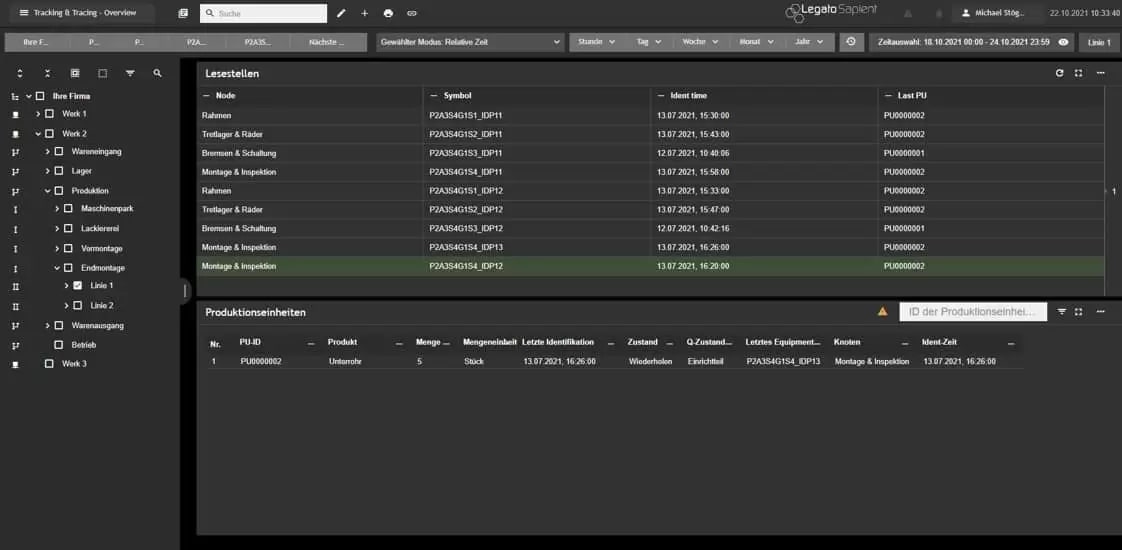

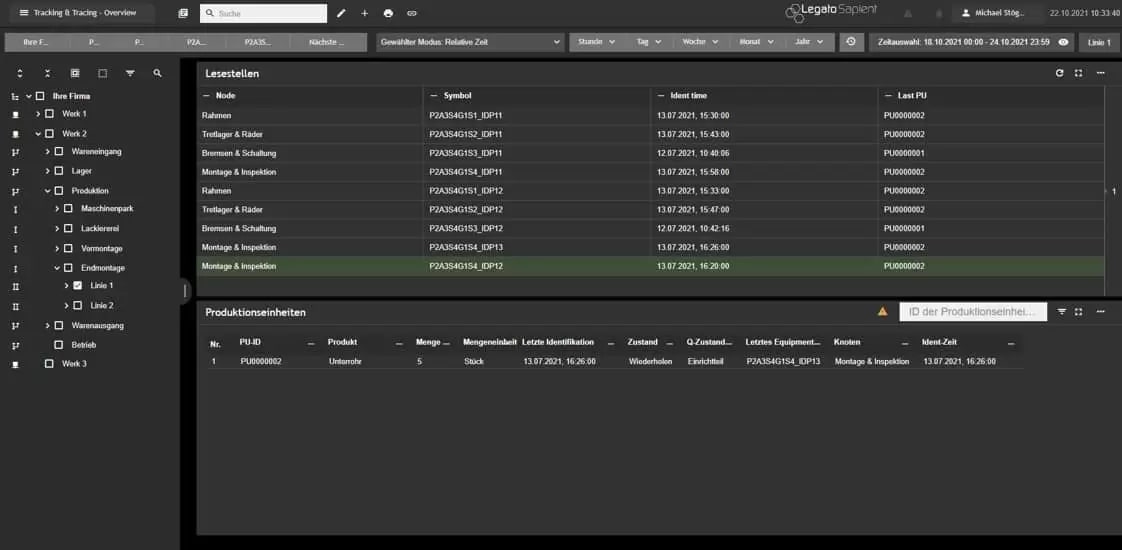

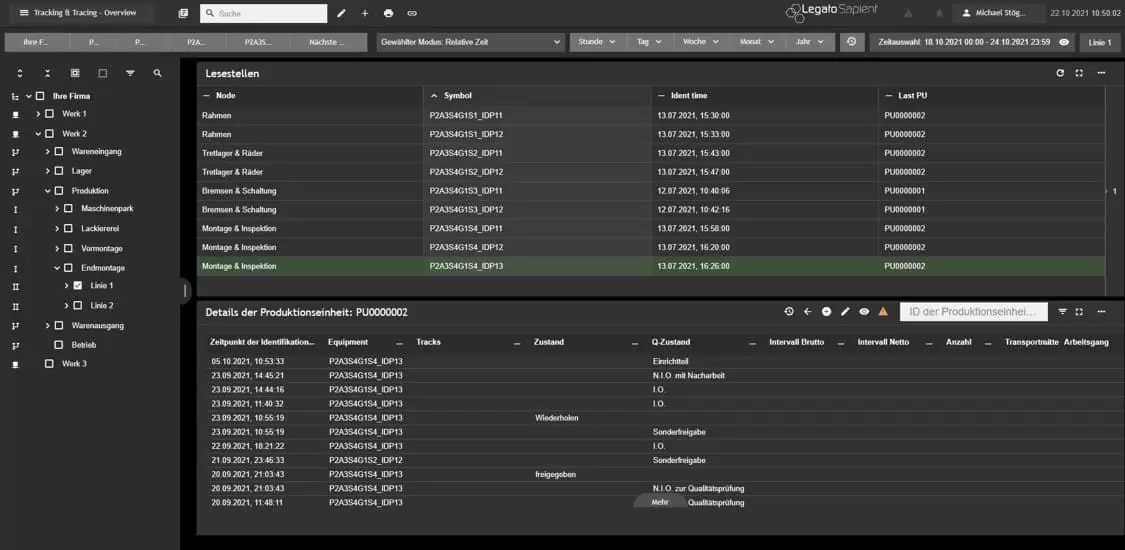

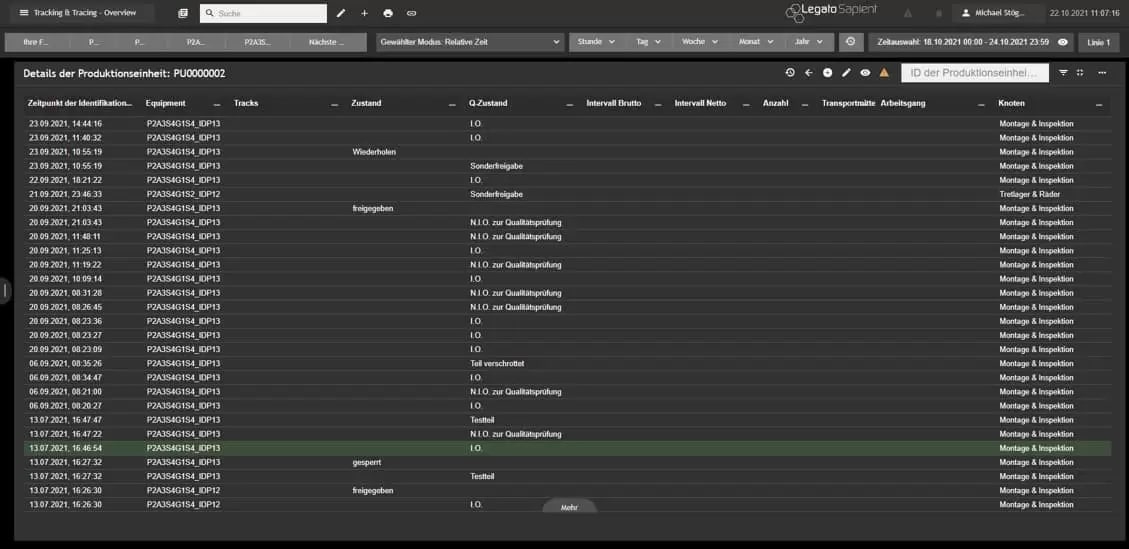

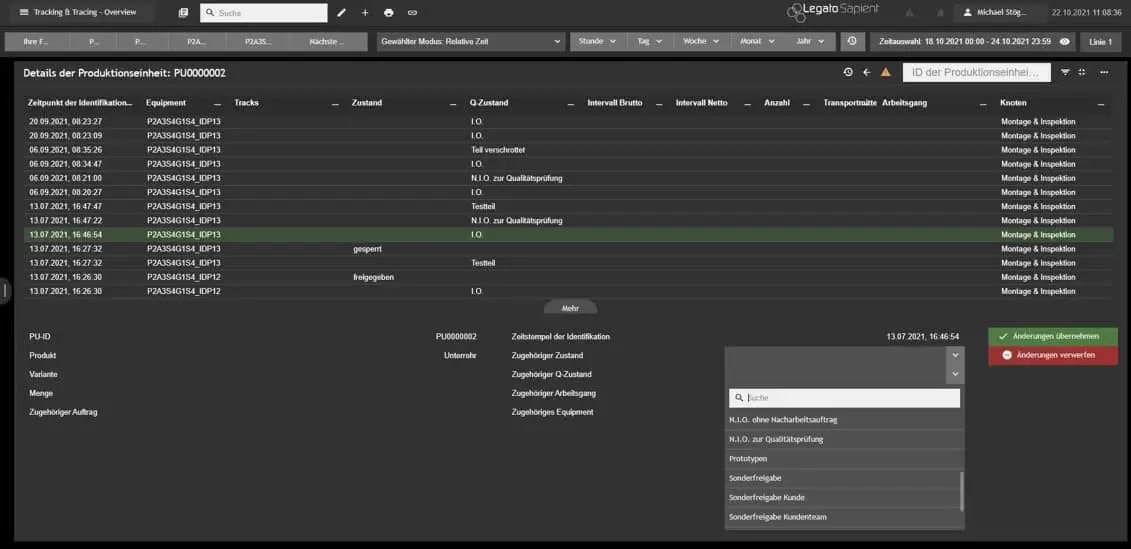

Ideally, you will recognize quality problems in production at an early stage and take immediate action. If a recall or rework is still necessary, it must be carried out quickly and in a targeted manner. Automated track and trace solutions are necessary to enable the traceability of components in production.