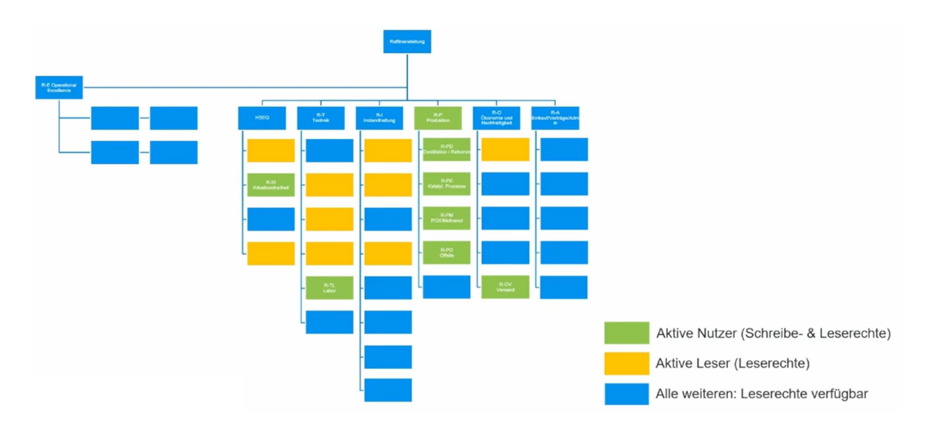

TotalEnergies Raffinerie Mitteldeutschland has been using the Finito shift management solution from Germanedge since 2013. The software is used at the site in a total of five operations – including three production plants, an off-site tank farm and in the loading area. This means that the tool is not only used in various operational areas of the refinery, but also acts as an interface to quality, environmental protection and occupational/plant safety.

With a throughput of 12 million tons, the Central German refinery is TotalEnergies’ largest refinery site in Germany. This makes Leuna the third largest refinery in the country.

TotalEnergies is a globally active, broad-based energy company in the fields of oil, gas, electricity, hydrogen, biomass, wind and solar energy. In terms of size: Annual turnover amounted to more than USD 281 billion in 2022. More than 105,000 employees worked for the Group worldwide in 2020.