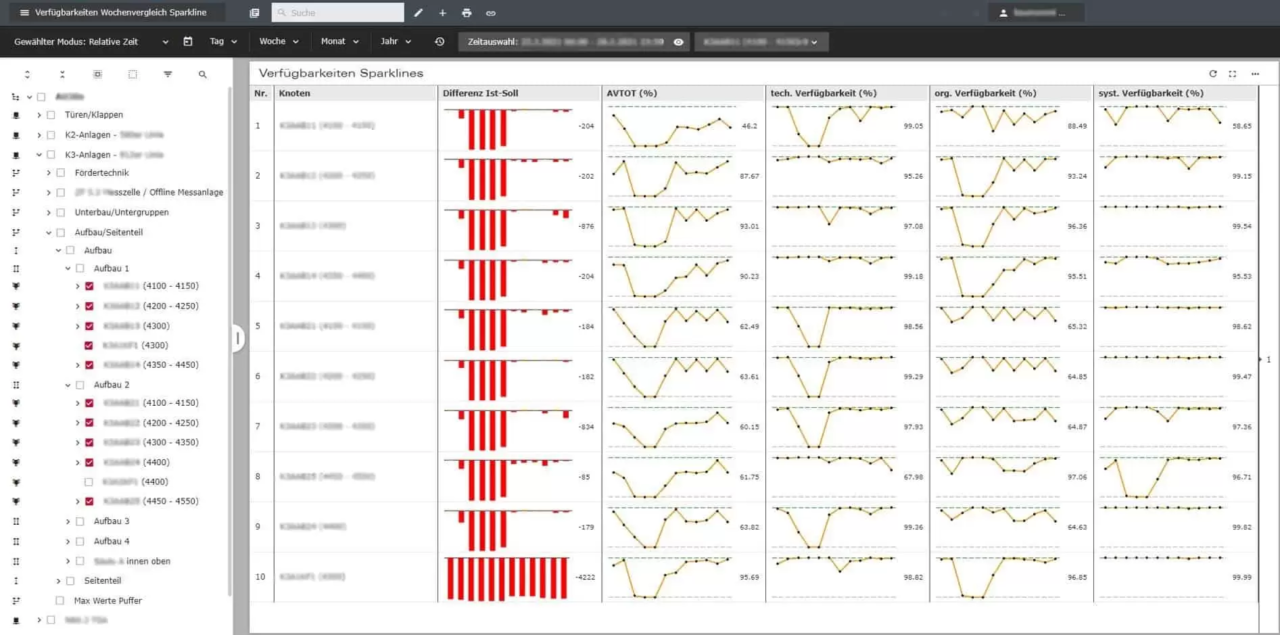

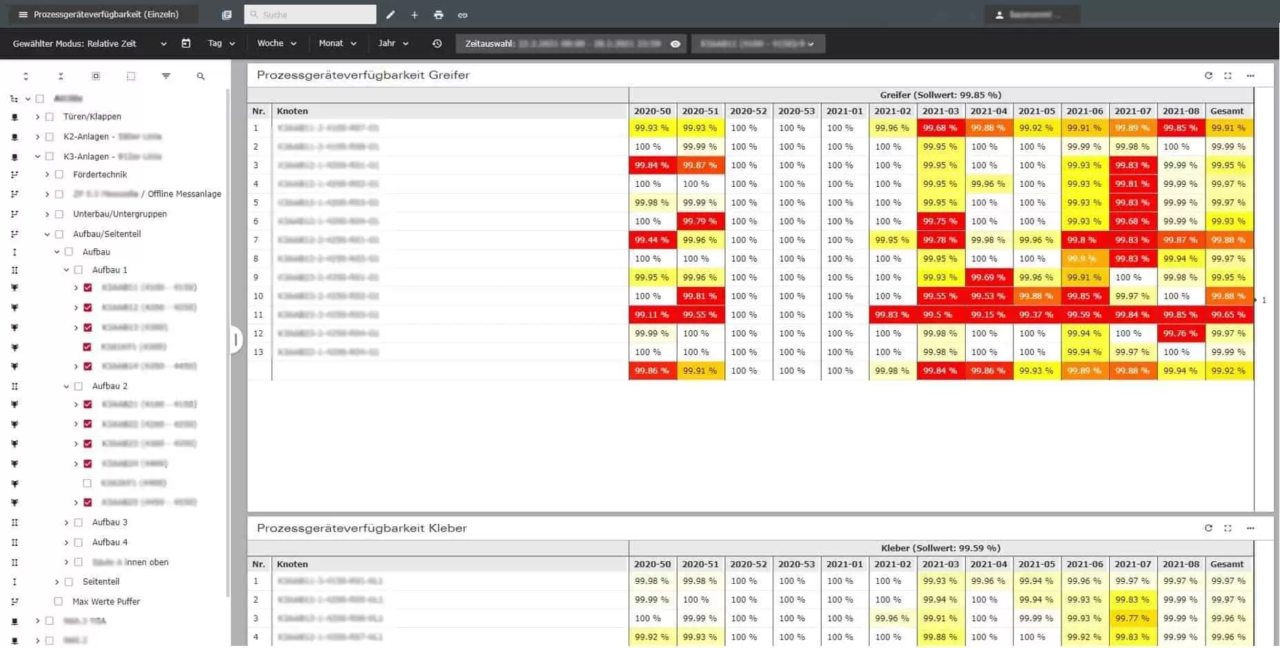

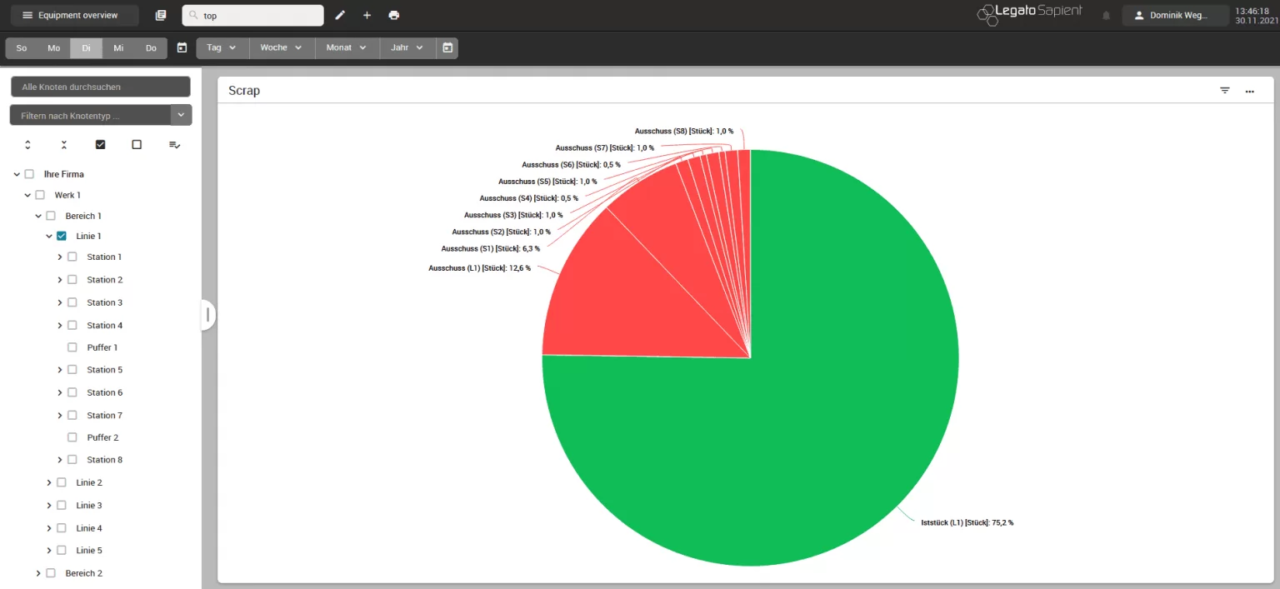

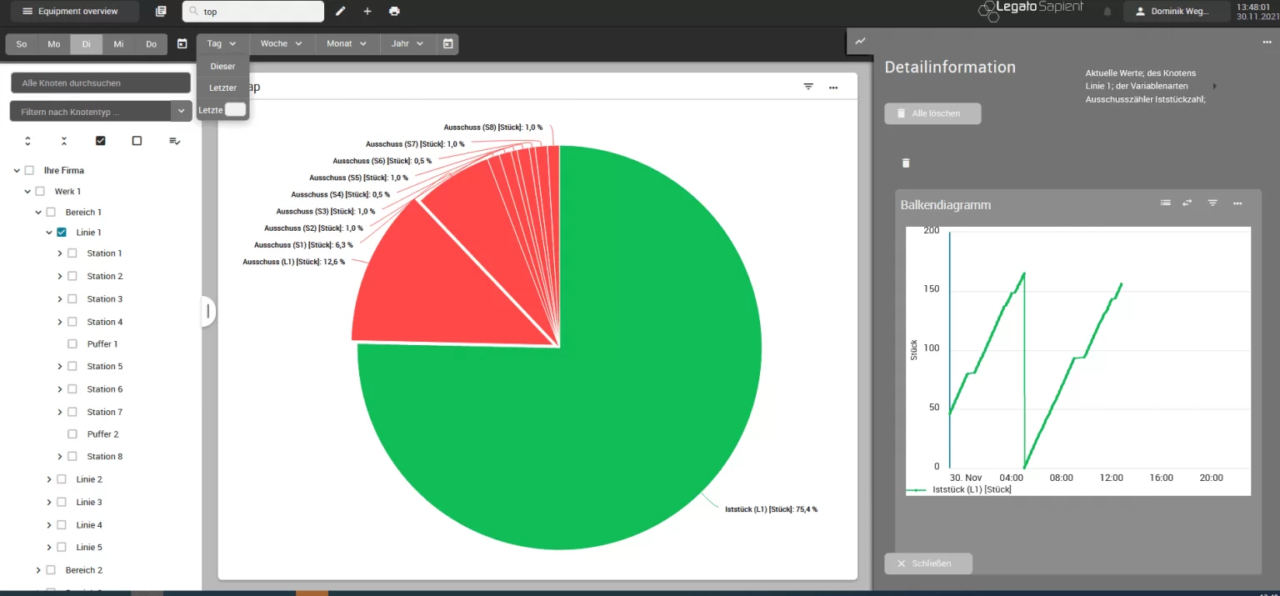

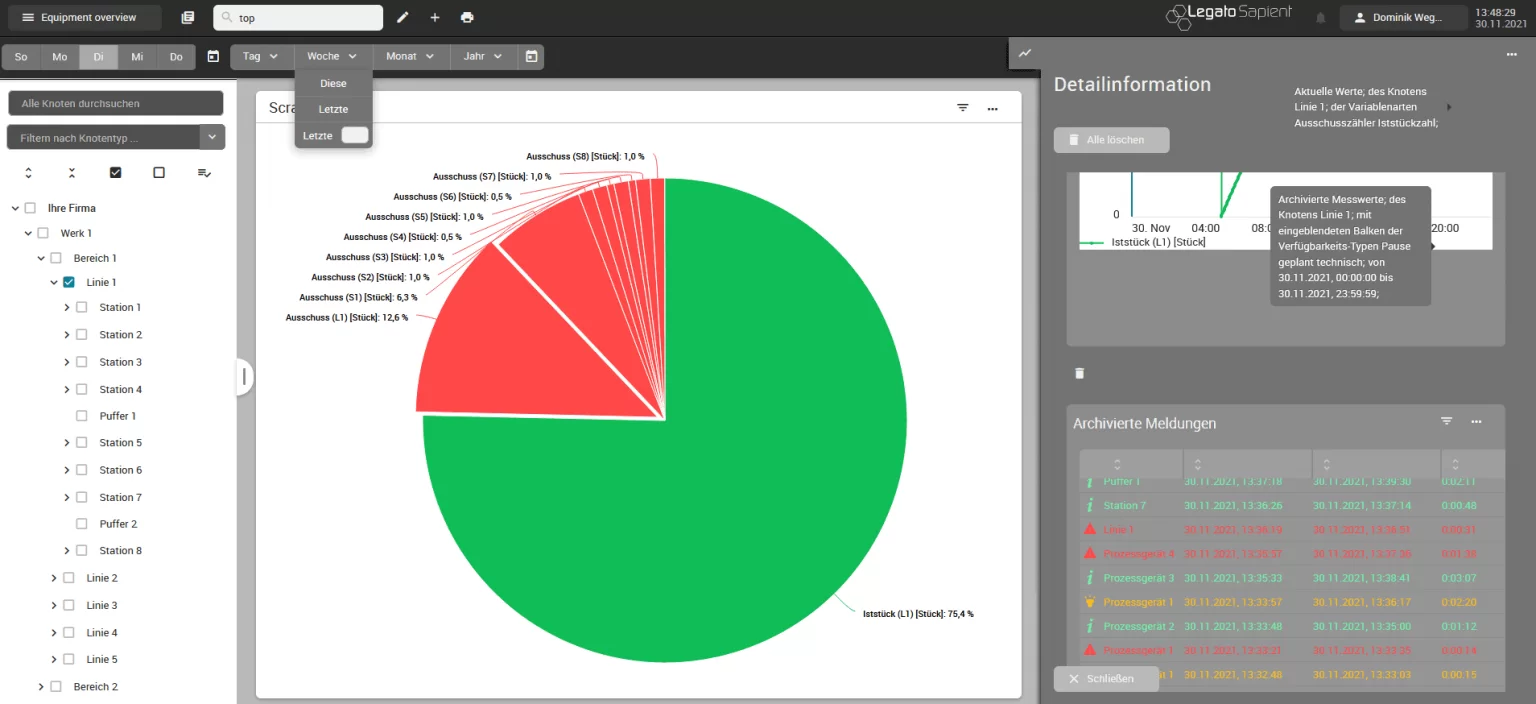

It is often started by looking at meaningful KPIs such as the production efficiency of an area or the plant availability. In the following screenshot, several areas or systems can be compared with each other via “Multiselect”. In this case, the output (actual vs. target quantity) and availabilities (total, technical, organizational and system-related) are compared.

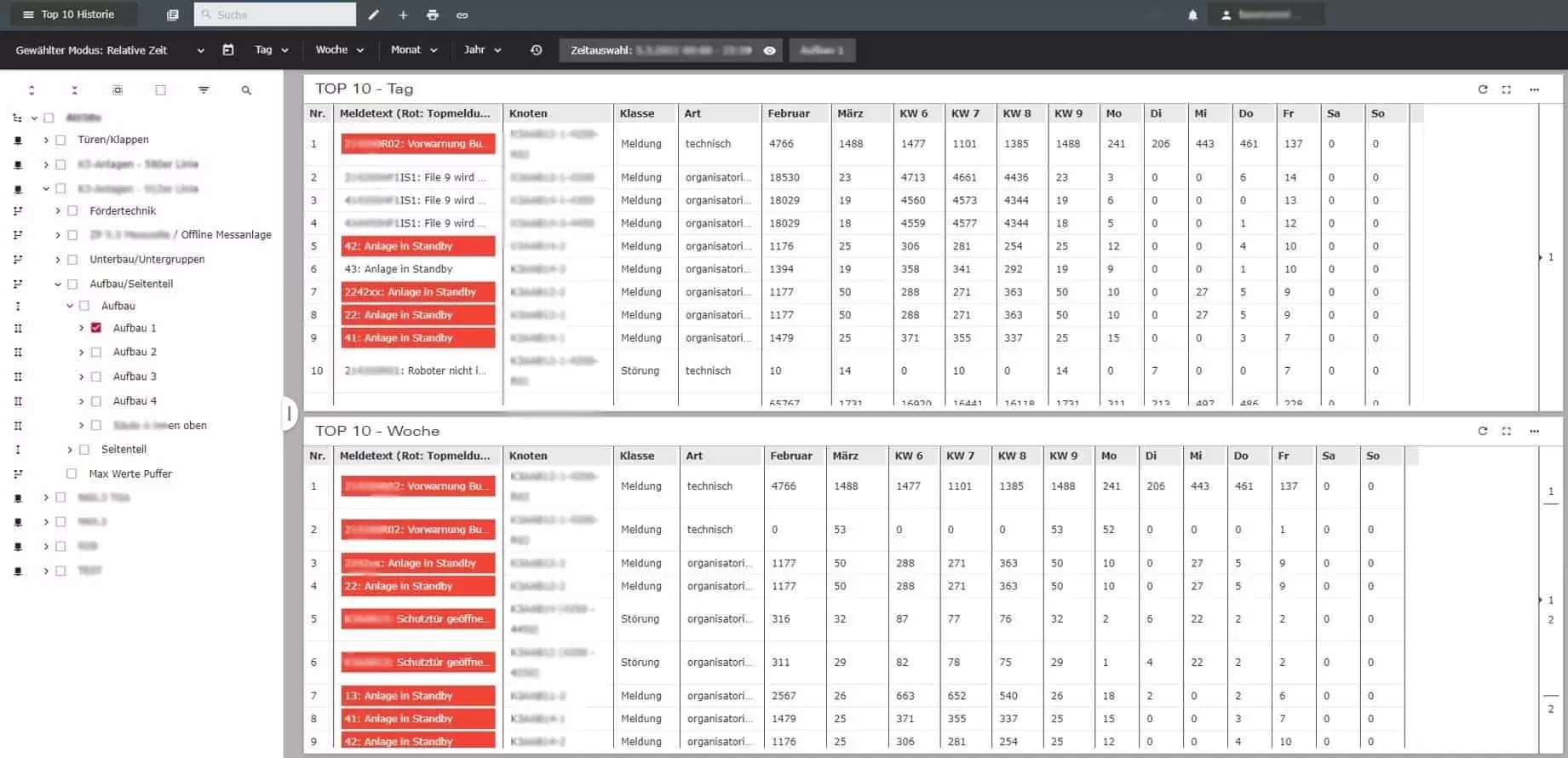

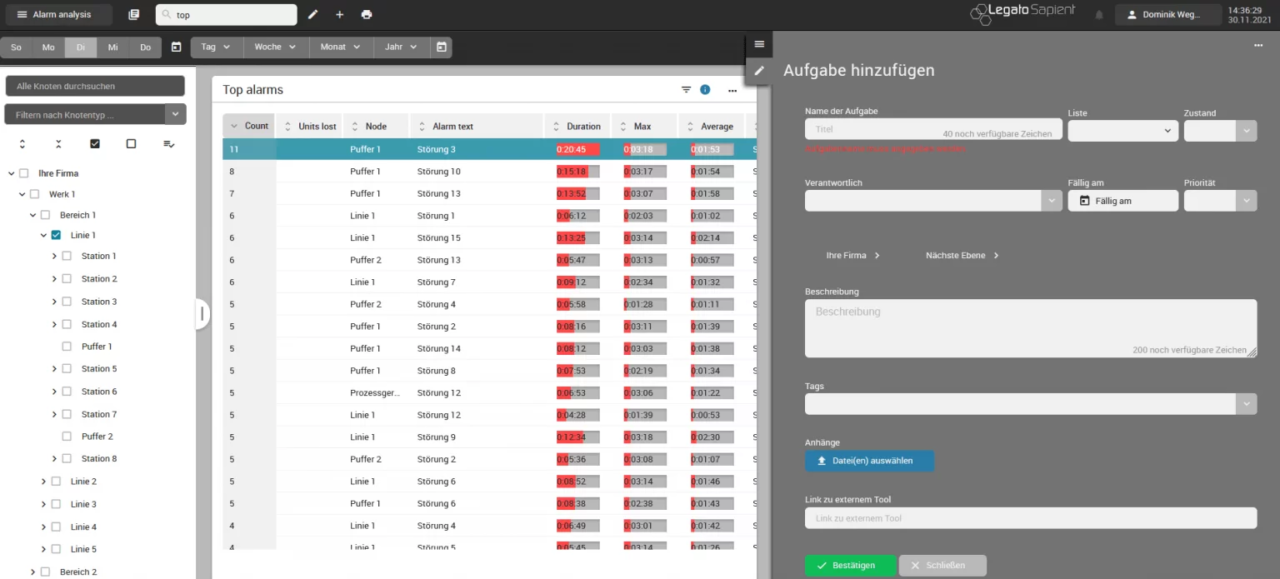

This comparison allows the “weakest” systems or areas, i.e. the “bottle necks”, to be identified. Based on this, a more in-depth analysis of the causes is then carried out. The typical fault evaluations, such as TopX faults, are used here. Determine the main causes and take preventive measures in the CIP.