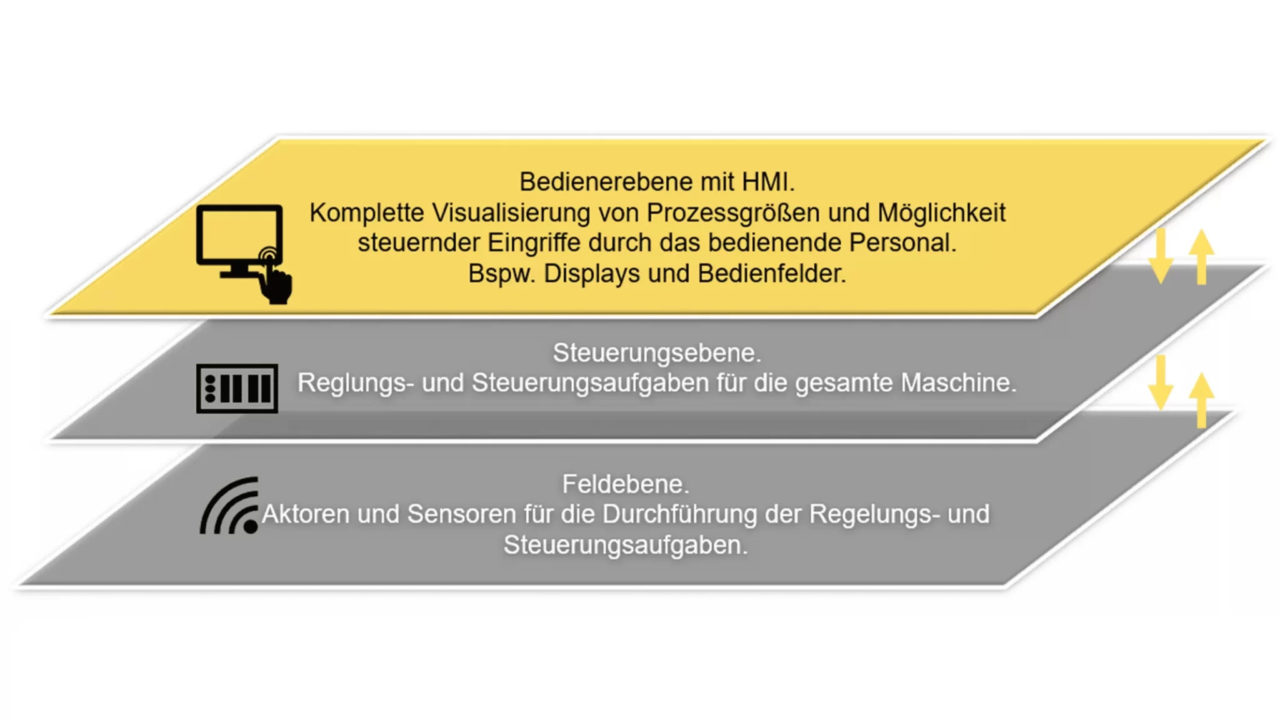

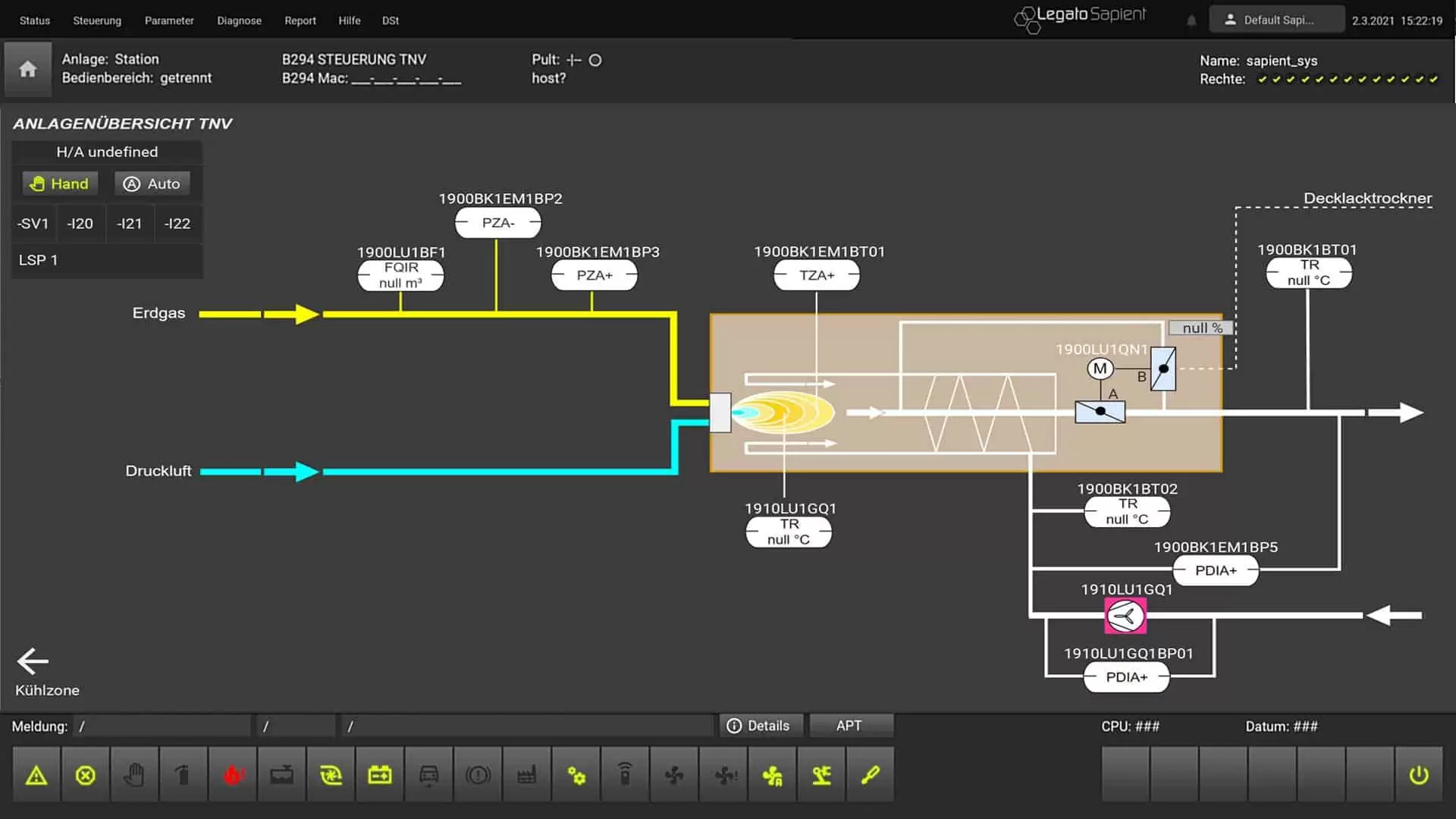

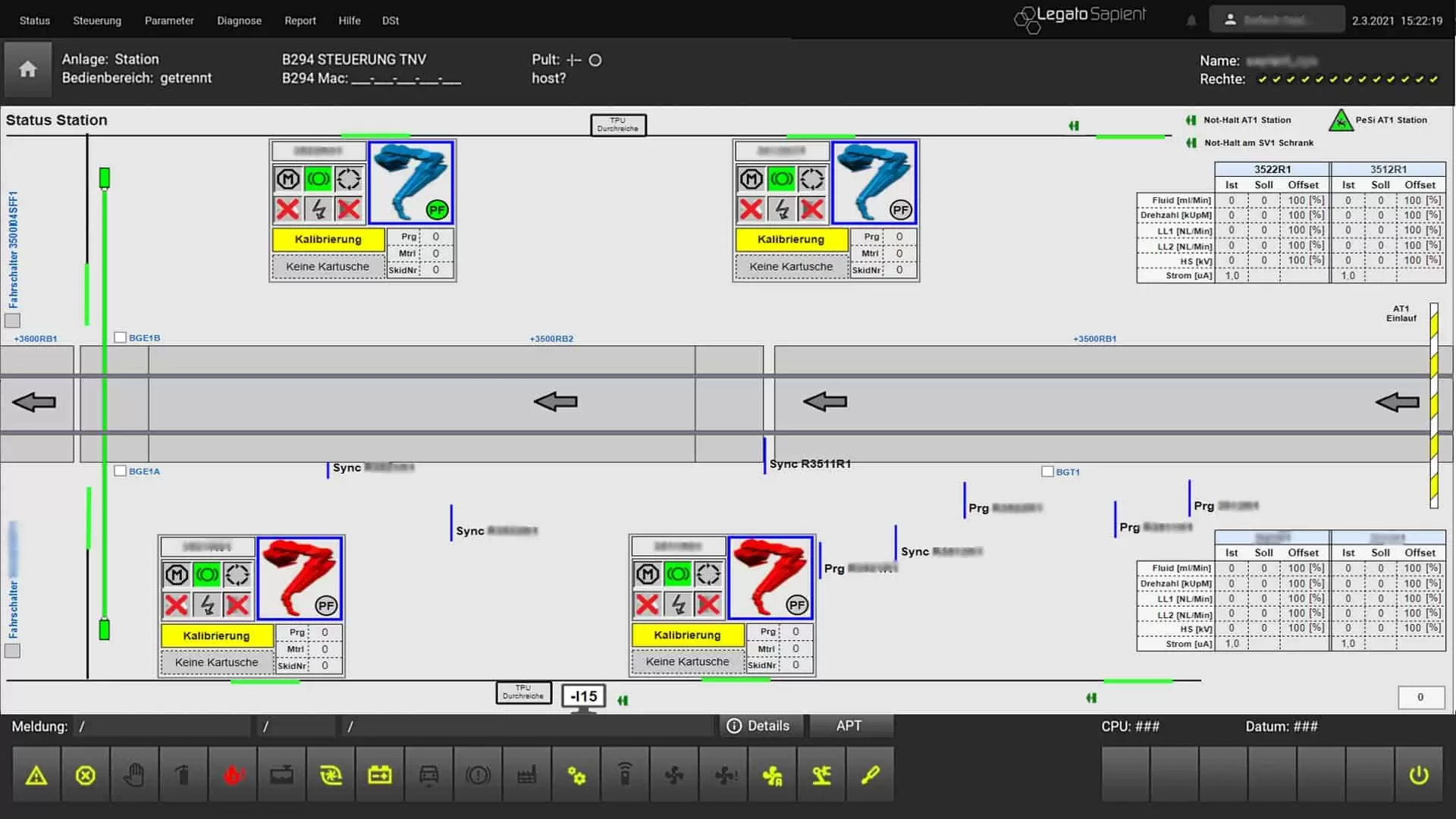

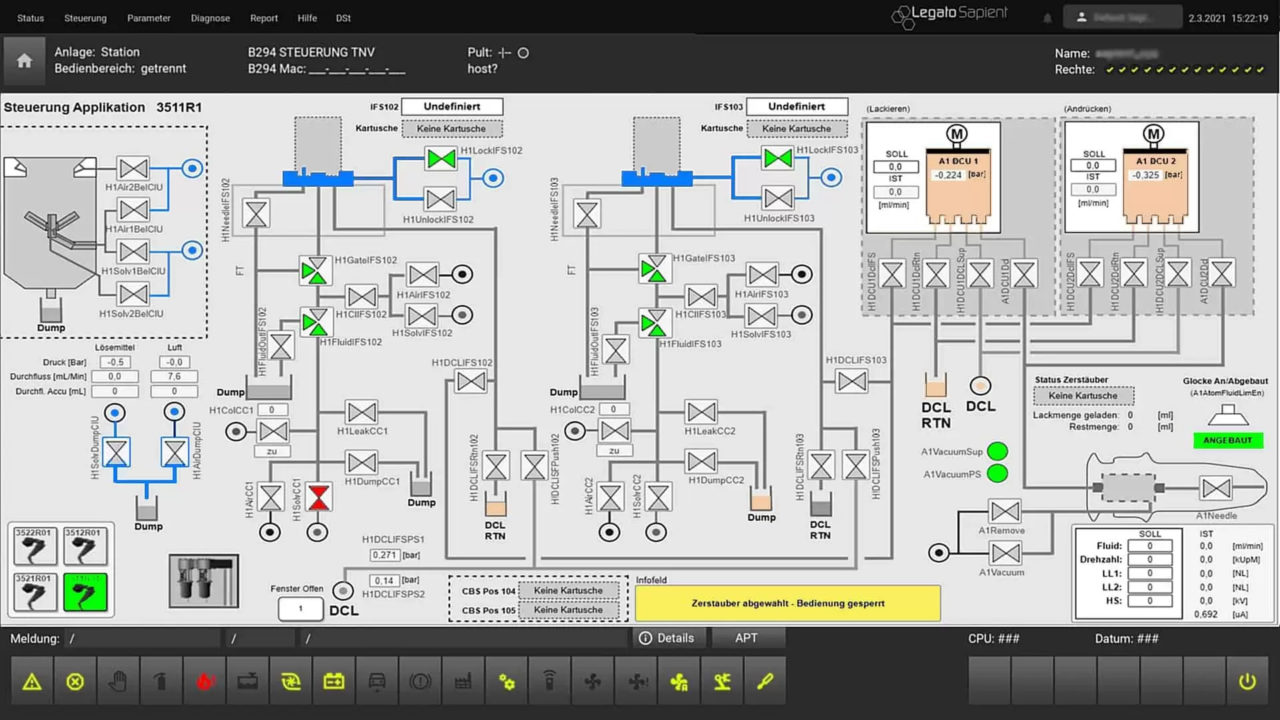

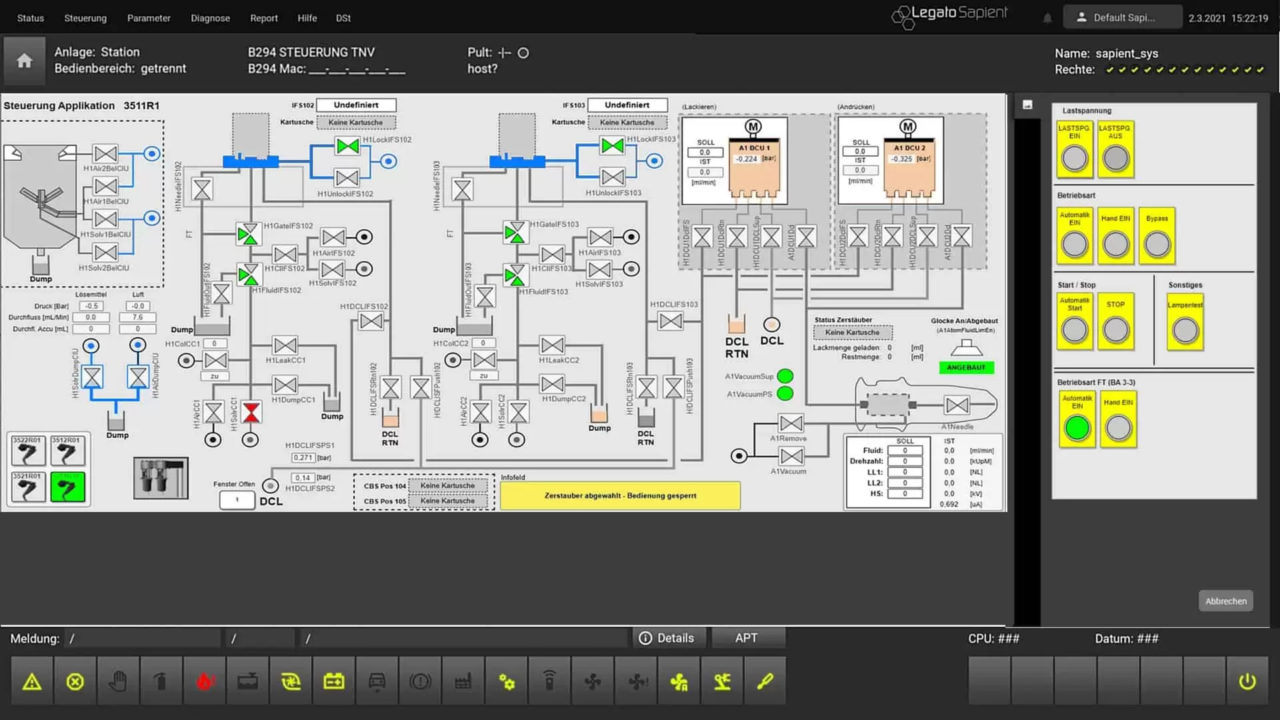

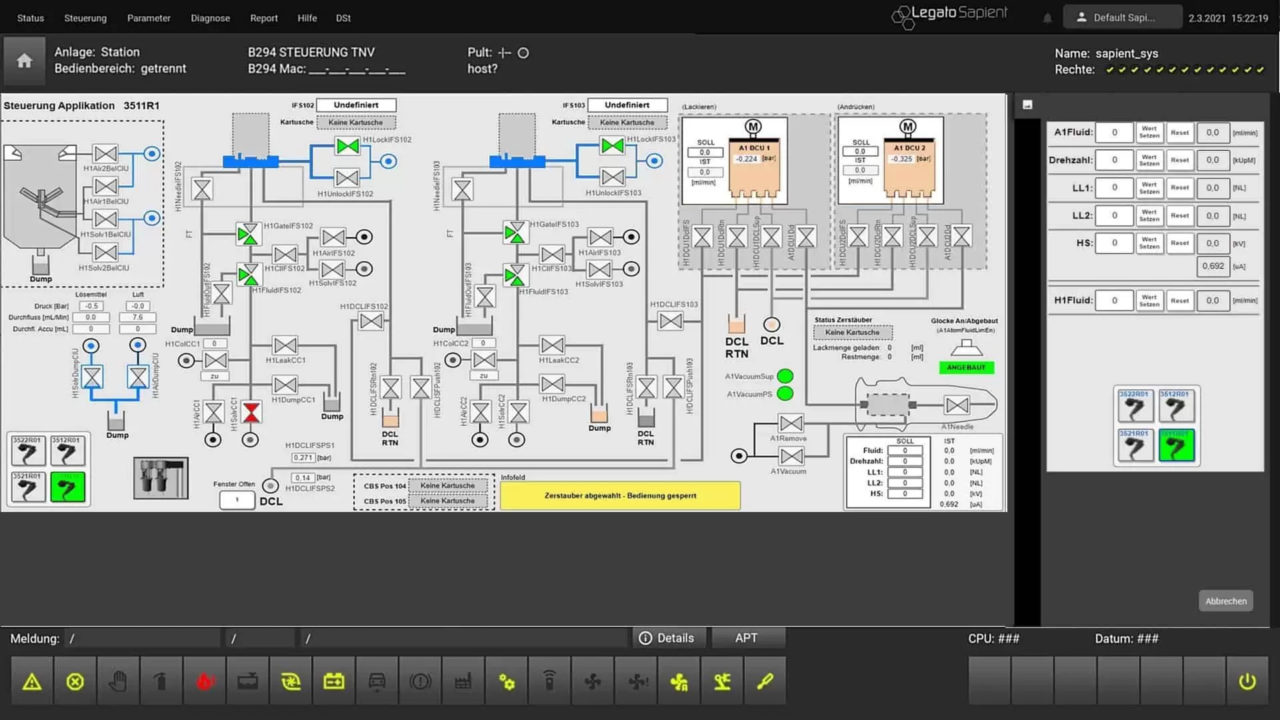

The separation between the control system level (MES) and the HMI, analogous to the classic automation pyramid, is often still common practice in manufacturing companies. However, heterogeneous system landscapes are not competitive in the long term. System discontinuities and a non-continuous flow of information are the order of the day, as important information from the HMI is usually only available locally as fat client solutions, although it would also be necessary elsewhere. Another not insignificant cost factor in the structure outlined is the expensive and maintenance-intensive hardware and middleware of the terminals.

Digitalization opens up new opportunities here: it is now possible to move away from the existing, local fat client installations in the HMI area, whereby a fail-safe network is required as a production-critical medium.