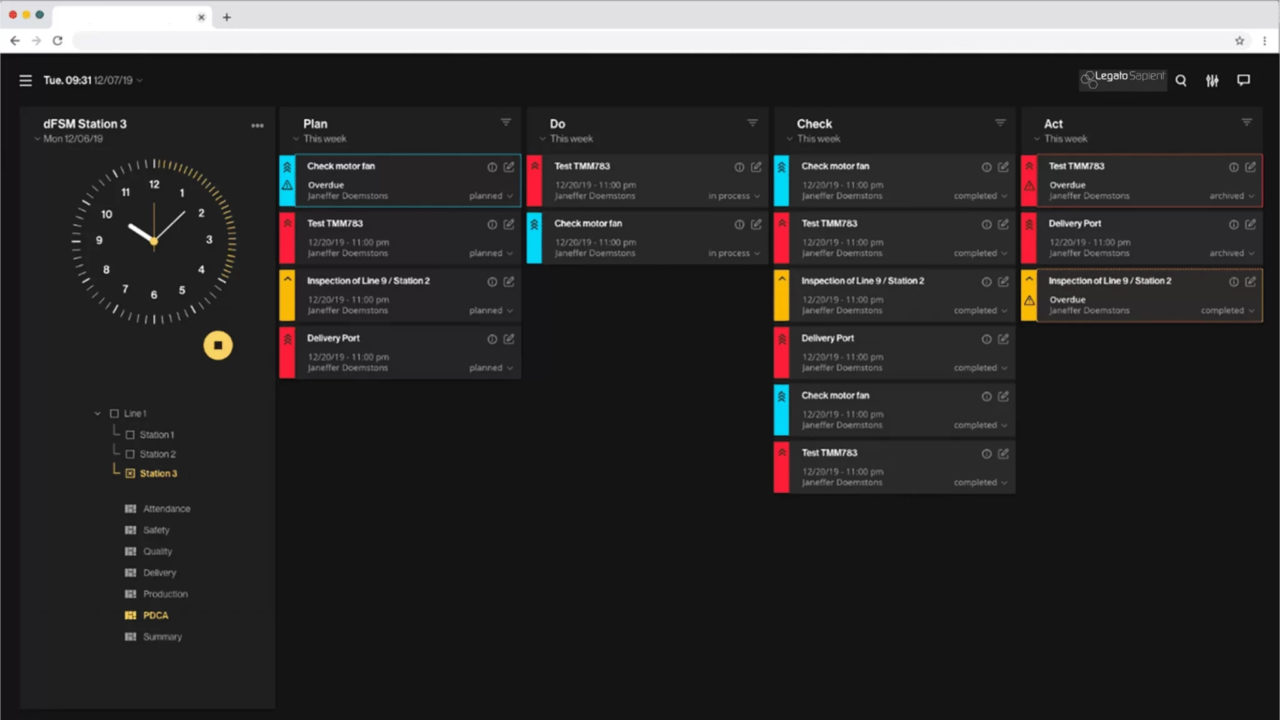

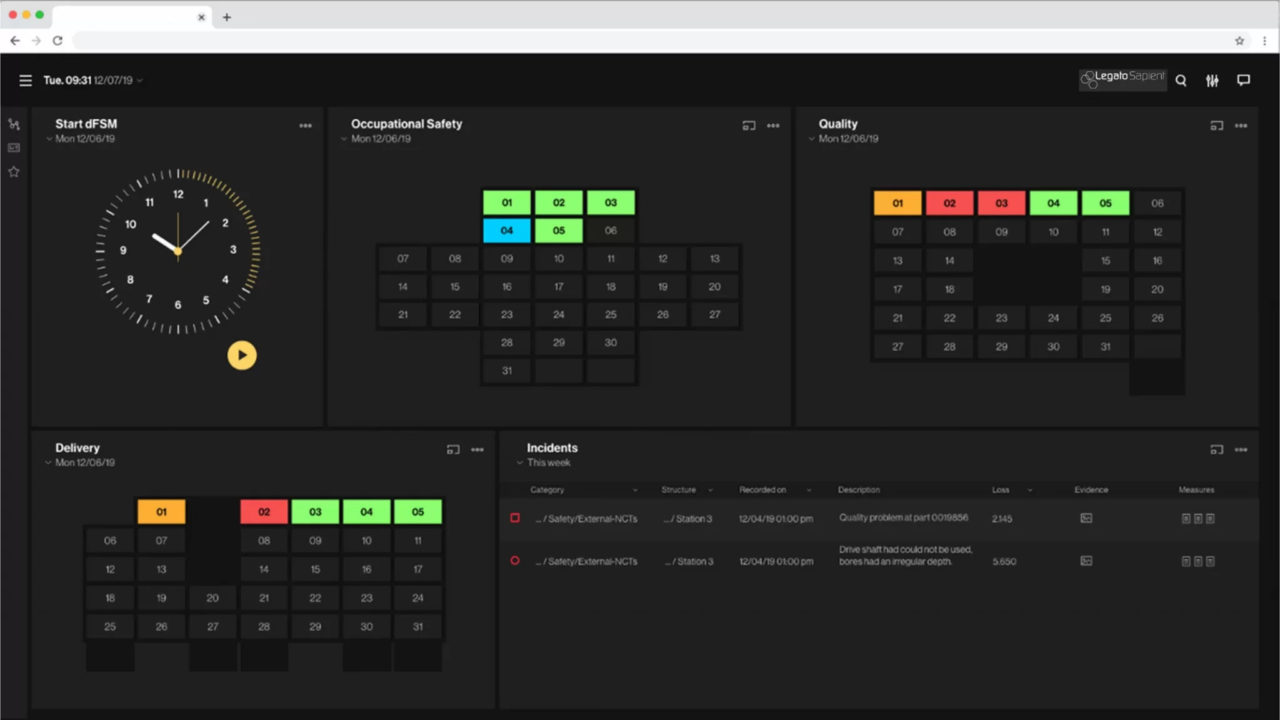

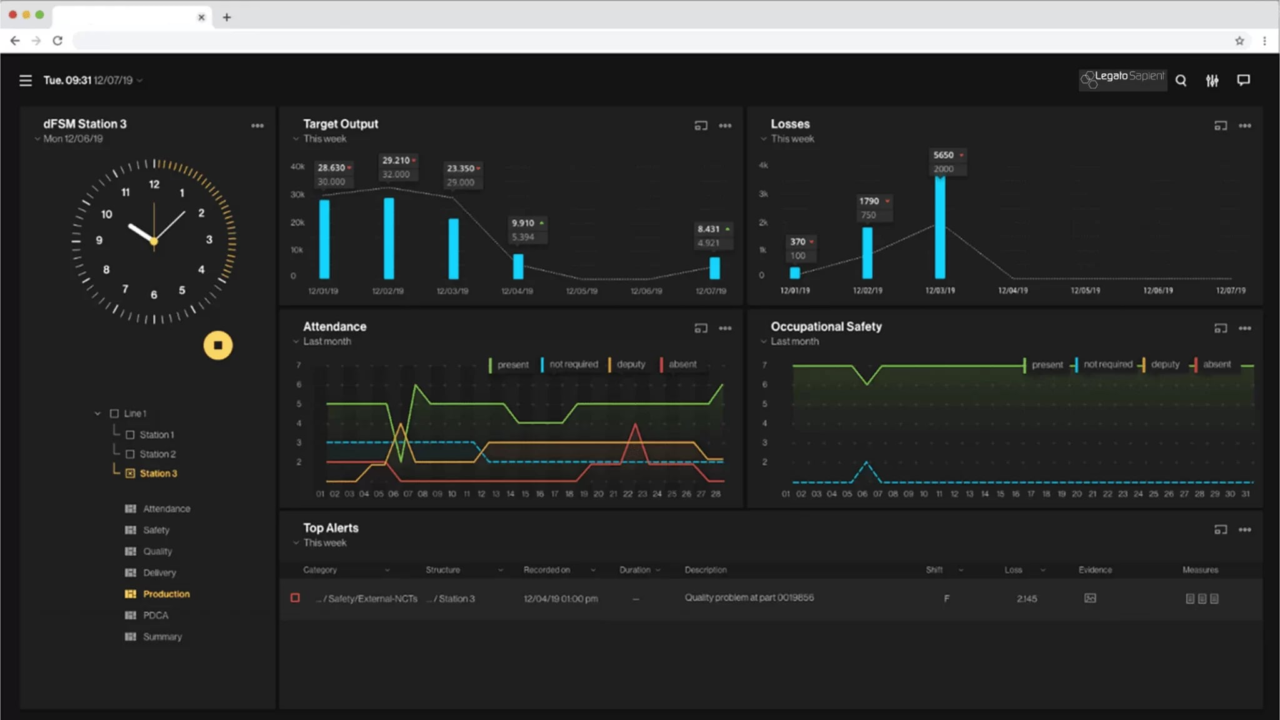

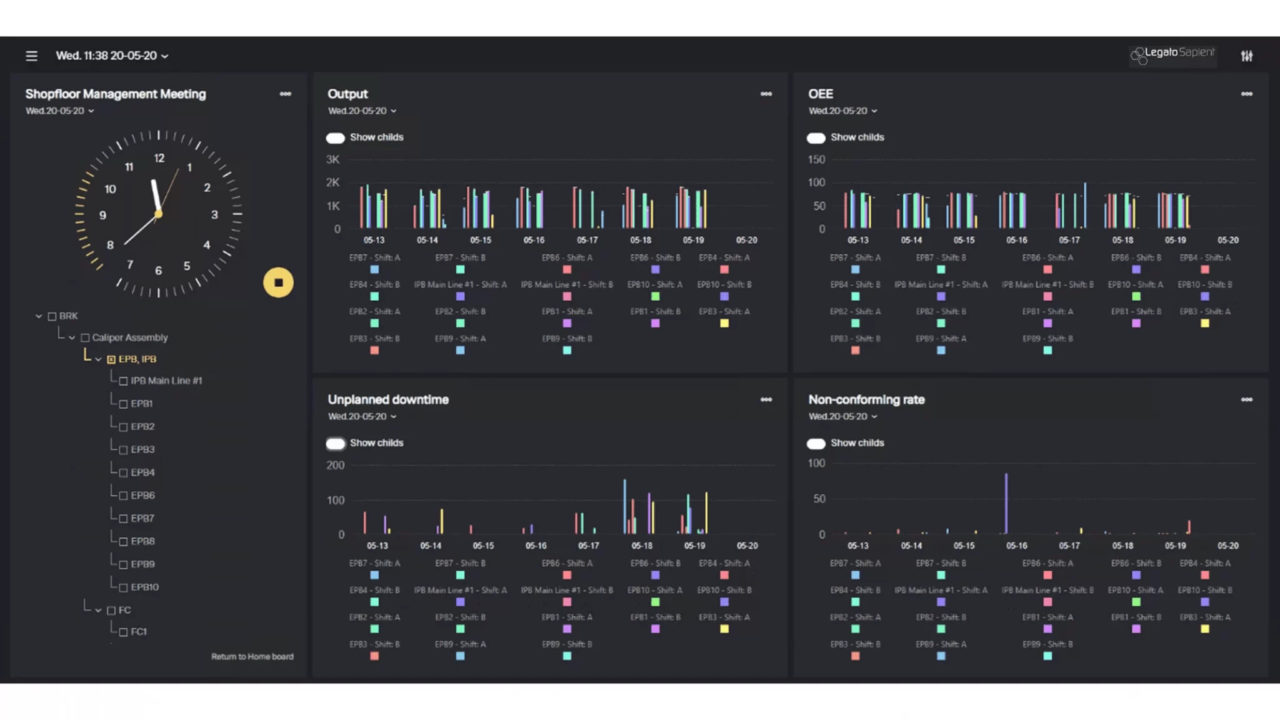

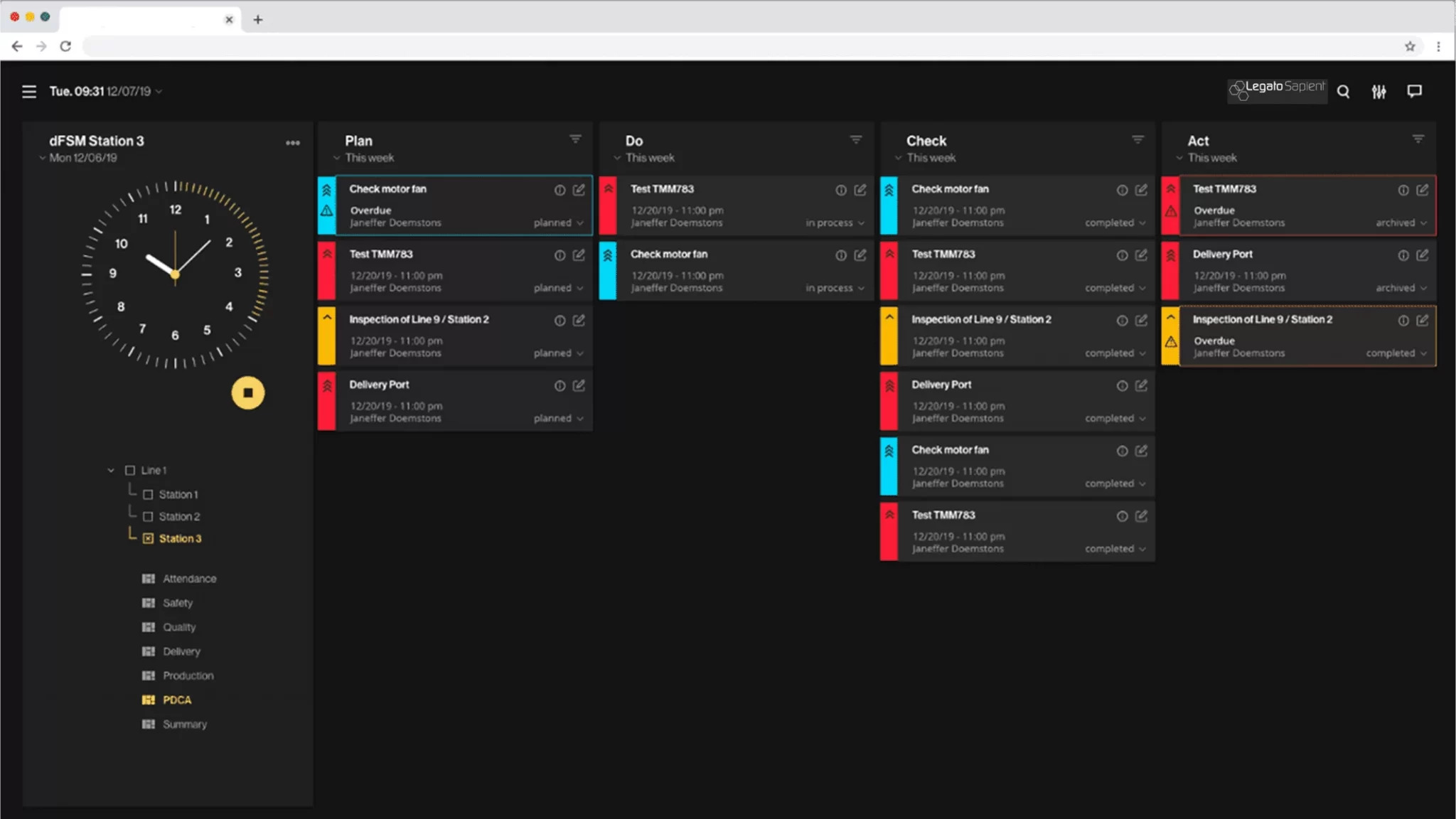

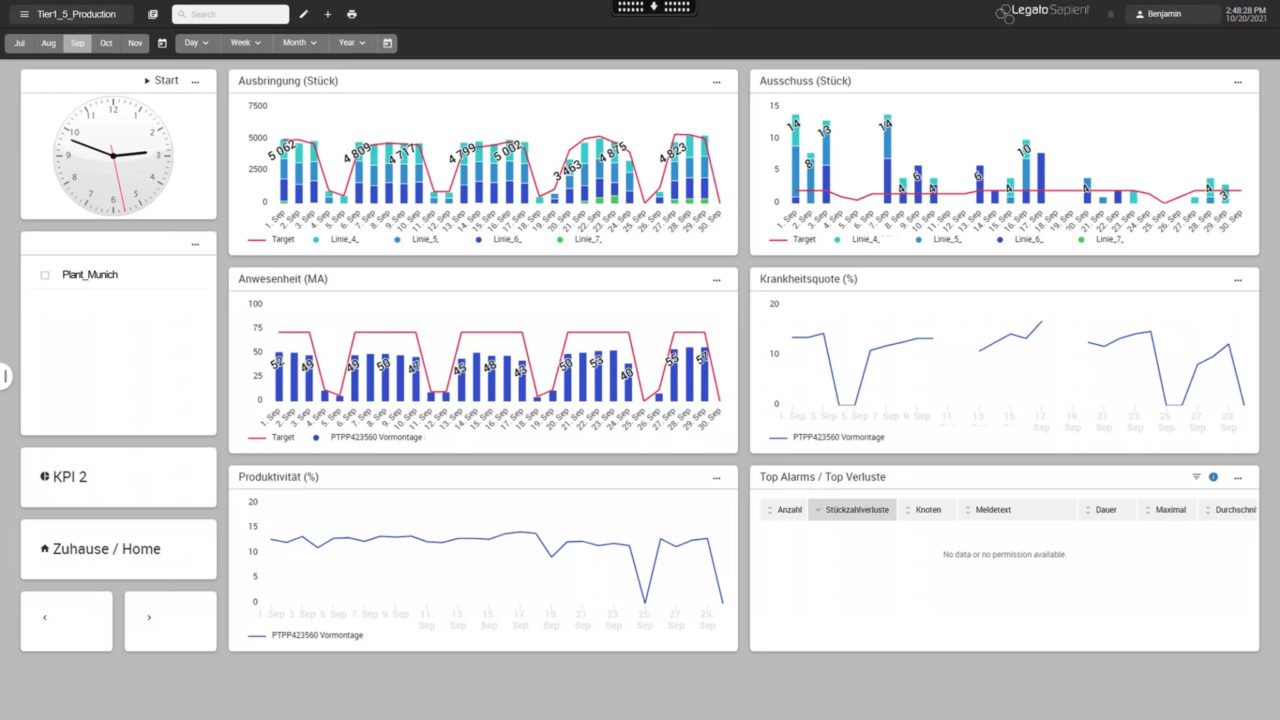

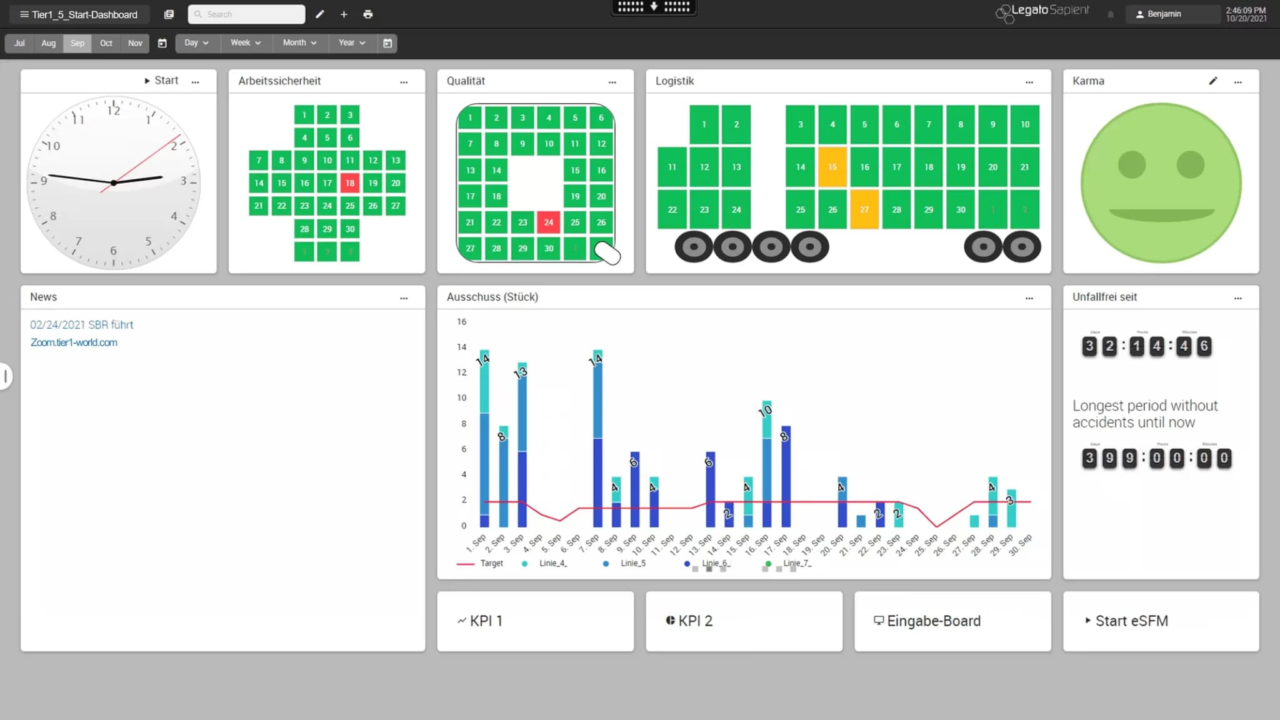

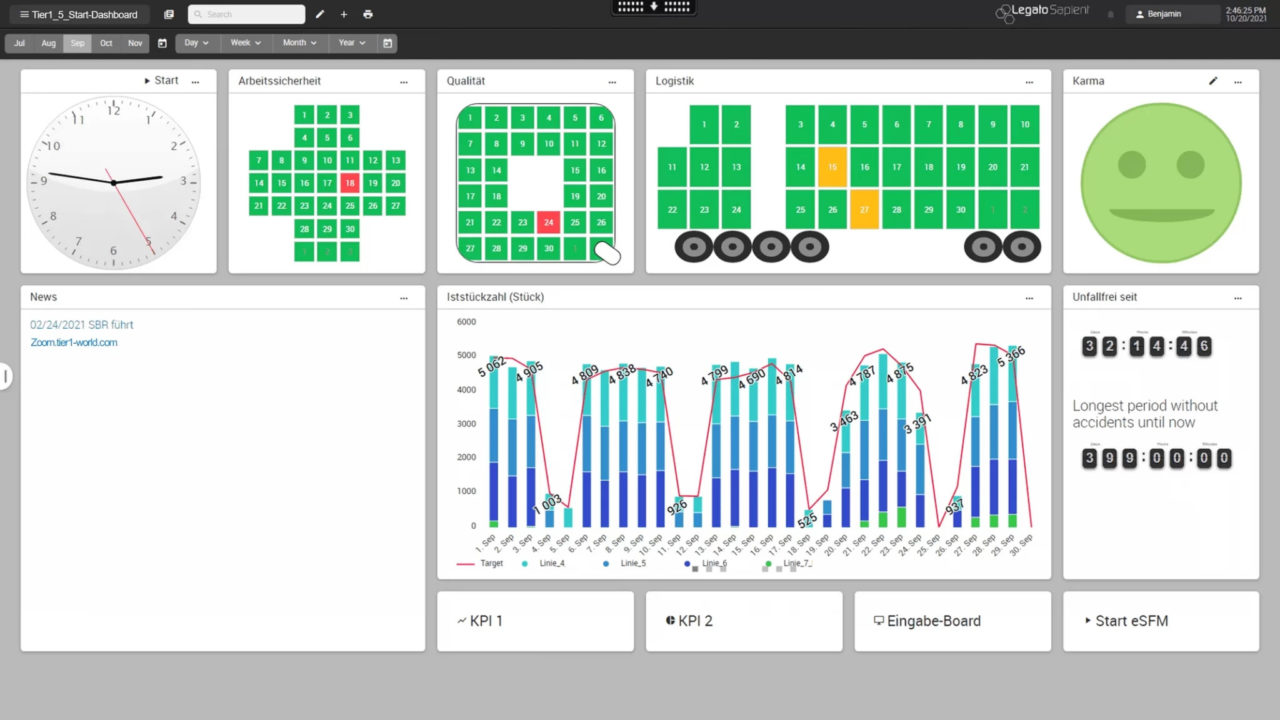

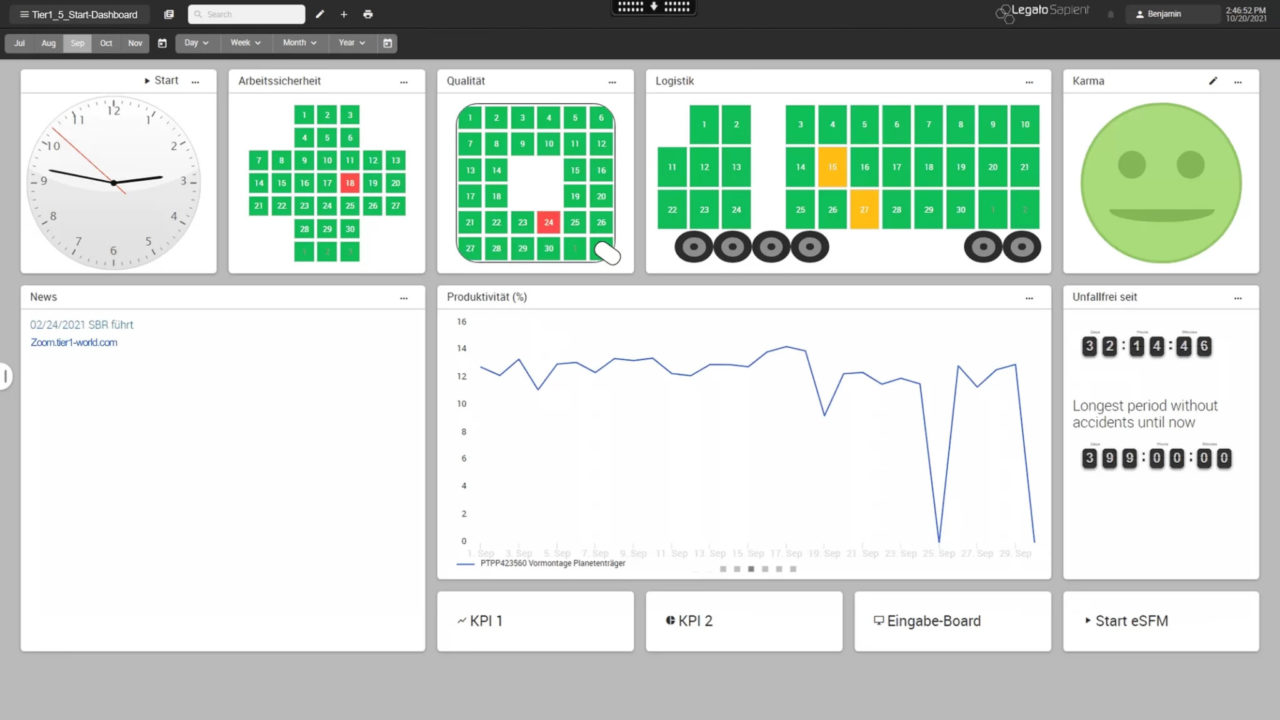

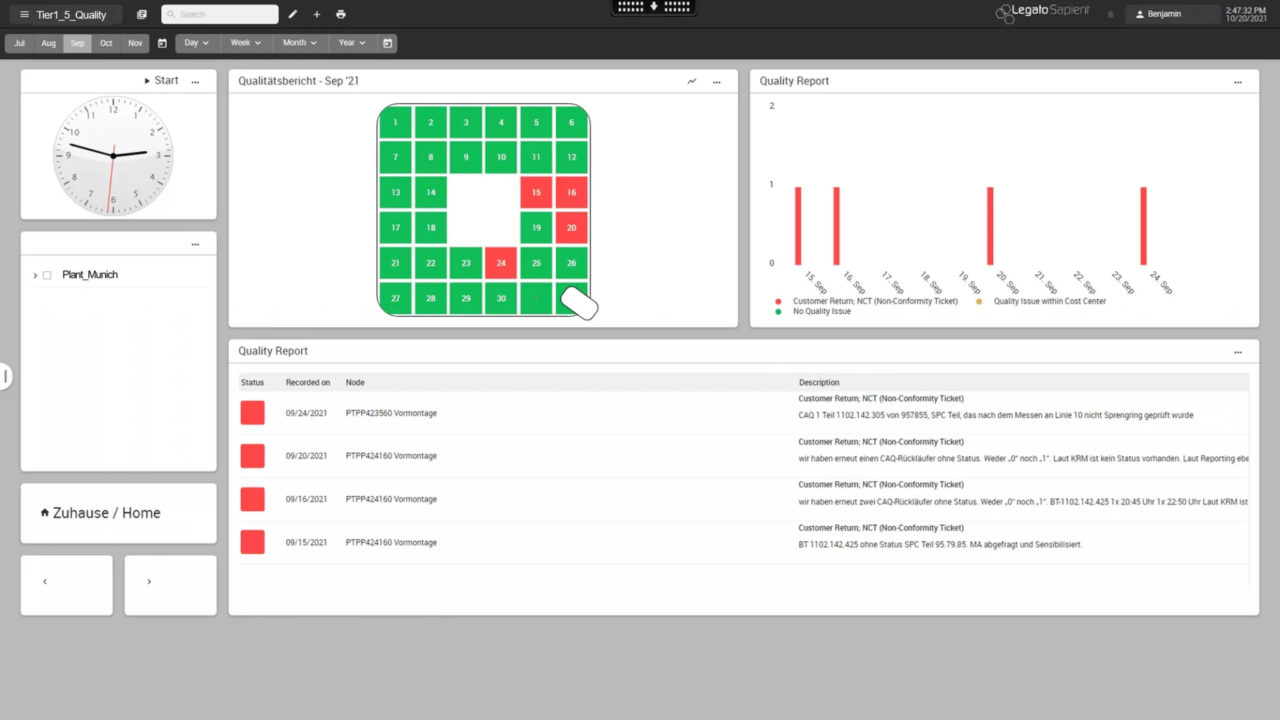

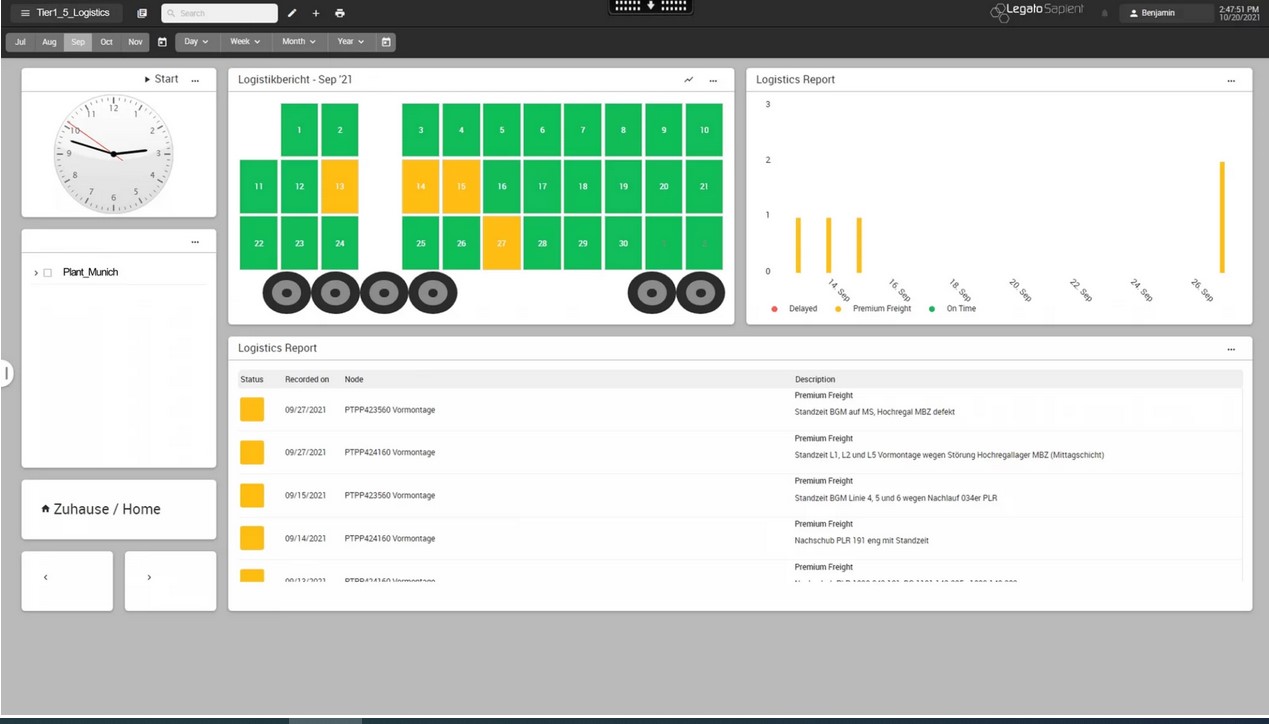

The digital dashboard provides direct access to the necessary data of all types and origins. You have several options for importing data:

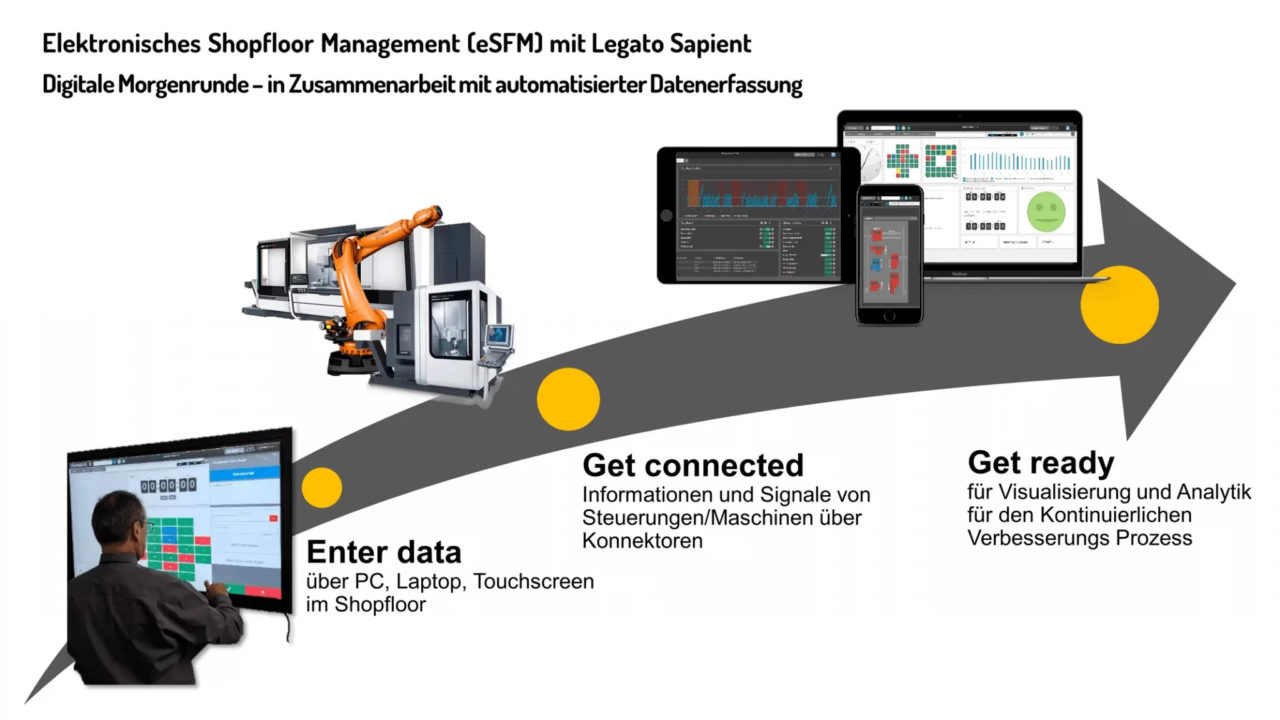

- Already available in the store floor system through machine data acquisition

- Manual input in the Interval Count Boardlet

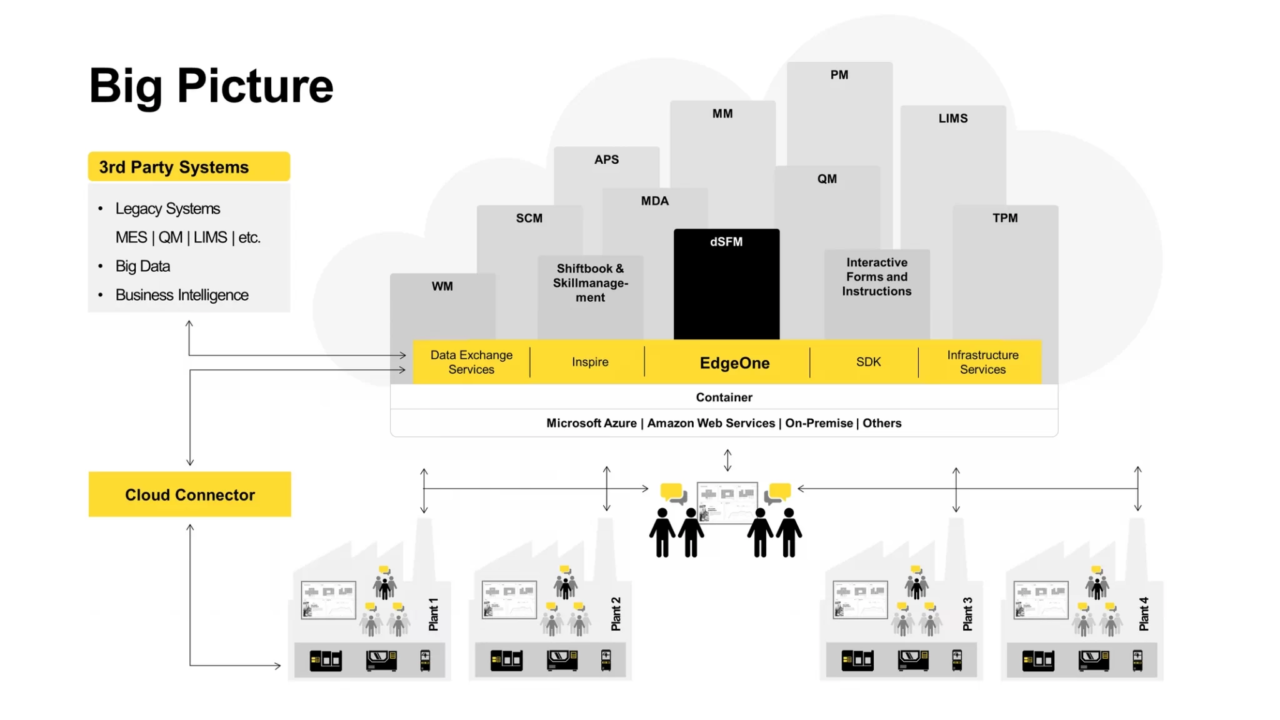

- Connection via dedicated interface to another system (e.g. SAP, legacy MES)

- File-based import via data that is regularly updated and read in