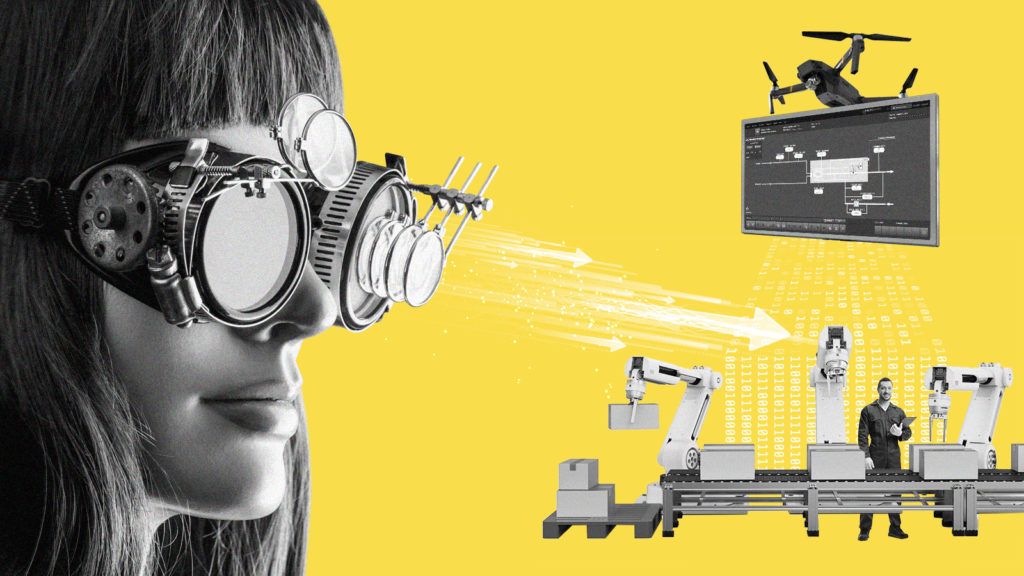

It is no longer just technology that is changing. People are doing it too. Besides the fact that many production companies are still digitising heterogeneously, the technologies must also be adapted to the new needs and requirements of people. So the question is no longer just how to connect the control level with the shop floor, but also what the human-machine interface of tomorrow must look like.

A Human Machine Interface (HMI) addresses two areas: the clear presentation of information and the simple operation of the machine. Thus, the machine function has long since ceased to consist solely of component control; it should also include the monitoring and analysis of production and performance data. To achieve this enhanced functionality, the focus must shift from a machine-centric to an operator-centric approach. Efficient communication between machine and human depends on the ability of both to use data in such a way that the whole enterprise ends up smarter.

These developments shape modern HMIs

To be truly future-proof and valuable, HMIs must take into account various trends in digital production:

1. Highly interconnected components Qualified personnel are becoming scarcer and interfaces need to be simplified to increase efficiency. This is made possible by integrating different systems and data sets into one interface.

2. Disruptive technologies Operator interfaces are also being impacted by an ever-increasing wave of new technologies. Cobot breakthroughs, AGVs, 5G networks, indoor geo-localisation, contactless HMIs, cloud and edge computing, augmented reality, artificial intelligence and machine learning – to name a few. These developments will contribute to the creation, collection and processing of larger amounts of data, and promote the further convergence of information technology and operational technology.

3. Design The better the user interface design, the more efficient and productive human-machine interactions can be. Strategic use of colour and thoughtful symbolism are more important than ever to ensure a high level of comprehension despite increasing complexity.

4. Mobile human-machine interactions As machines are distributed across sites, manufacturing cells and lines, mobile human-machine interfaces become important productivity tools. At the same time, HMIs are becoming more portable via mobile devices.

A connection between control level and shop floor

Heterogeneous system landscapes are not competitive in the long run. This is where digitalisation opens up new opportunities: a move away from existing, local fat-client installations in the area of HMI is now possible, assuming a fail-safe network as a production-critical medium.

The combination of MES software with HMI enables a decentralised view of the machine with the overall view in the control room, thus ensuring a seamless flow of information and system continuity. This information must be displayed in an ergonomically sensible way for the worker so that he can grasp it quickly and react accordingly. This means that the operator no longer has to switch between systems for different information and a higher level of transparency is made possible, which in turn leads to faster reactions and less machine downtime.

Do you also want to connect your control level with the shop floor and thus not only make your employees’ work easier, but also create true business value? Read more about our MES solution Legato Sapient with HMI module here!