It has become an all-too-common habit to bash our German economy these days. No day goes by without just another press article calling out the “sick man of Europe” once again.

While it’s easy to highlight flaws and activate German Angst, providing solutions is much more challenging—and ultimately far more helpful.

Today, I want to focus our attention on some of the positive signals within the German industrial context and discuss what’s needed to get our country back on track.

What we need is “shock digitalization,” a concept that aims to end our incremental approach to digital transformation. Instead, we must fully commit to a rapid and comprehensive digital overhaul, even if the pace might unsettle our German mindset, characterized by a preference for safety and meticulous preparation.

One subject where the need for shock digitalization becomes crystal clear is the Lieferkettensorgfaltspflichtengesetz (LkSG).

Yes, it’s one of those ultra-long German words, but believe it or not, its English translation is even more complex: “Act on Corporate Due Diligence Obligations in Supply Chains.” Only we Germans could come up with such a translation!

But jokes aside, the LkSG, which has been in place since January 1, 2023, is a significant development for a better and fairer globalized world. It mandates that enterprises in Germany with at least 3,000 employees ensure their supply chains adhere to critical human rights and environmental standards.

Specifically, the LkSG requires companies to:

- Identify risks related to human rights and environmental violations within their supply chains.

- Implement preventive measures to address these risks.

- Establish a complaints procedure for affected persons.

- Regularly report on their due diligence activities.

This act represents a massive step forward because A) it promises to make supply chains more transparent, ethical, and sustainable, and B) it’s an initiative that enhances corporate responsibility and “forces” businesses to innovate and digitize their supply chain management.

The LkSG Challenge: From Fax Machines to Compliance

What does the LkSG have to do with shock digitalization, you might ask?

In all fairness, many companies in Germany won’t necessarily consider the LkSG good news, given the considerable effort required to ensure its execution. This is particularly challenging for companies lagging behind in digital transformation—a phenomenon I have written about before.

Quick reminder: The German economy scores below the EU average across all four major digital metrics defined by the European Commission.

Our country’s slow pace in digital transformation is further highlighted by another significant, even though less encouraging, milestone.

Germany is still heavily reliant on fax machines.

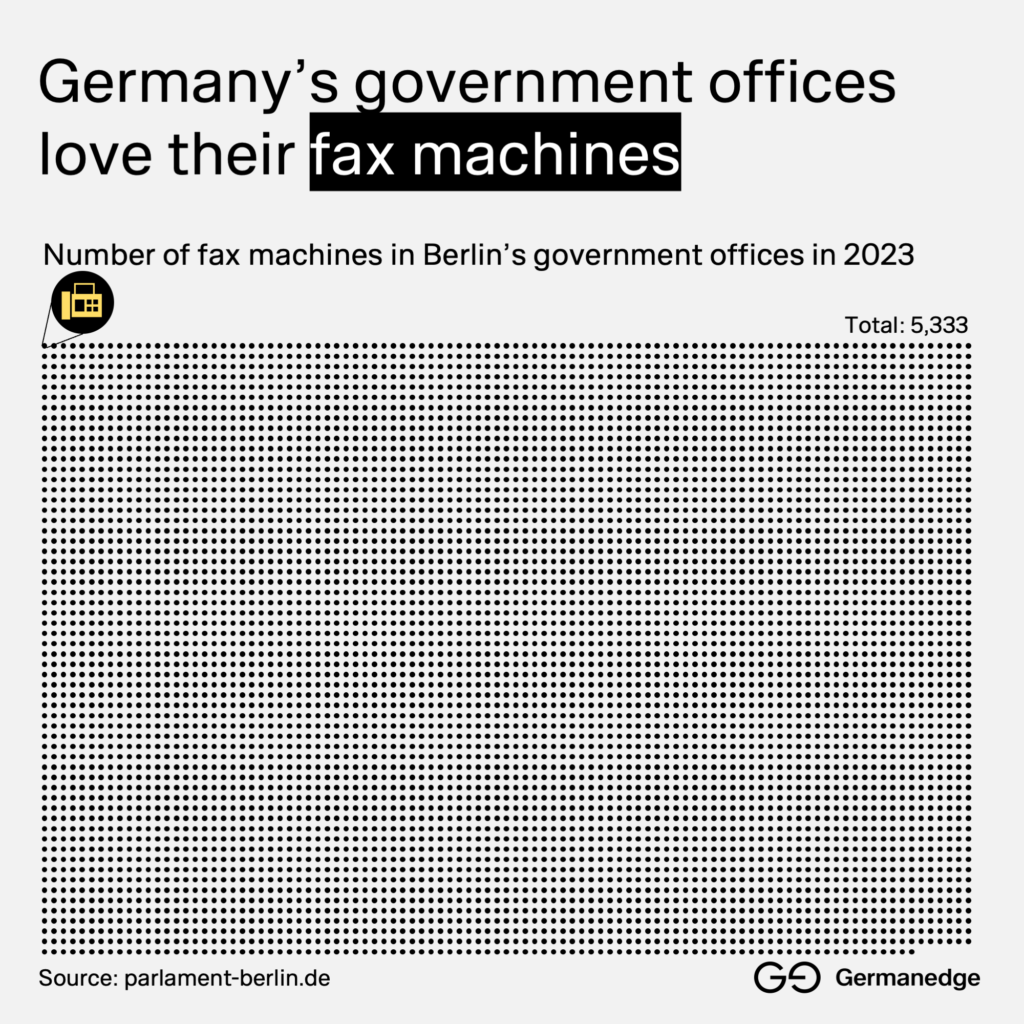

Can you imagine that the German government is still in the process of phasing out its thousands of fax machines as we speak? It’s true. After an internal investigation last year revealed that 189 out of 731 administrative services in Berlin could only be processed by fax, the decision was made to shut down the 5,333 fax machines still in operation across Berlin’s administrative offices by June 30, 2024.

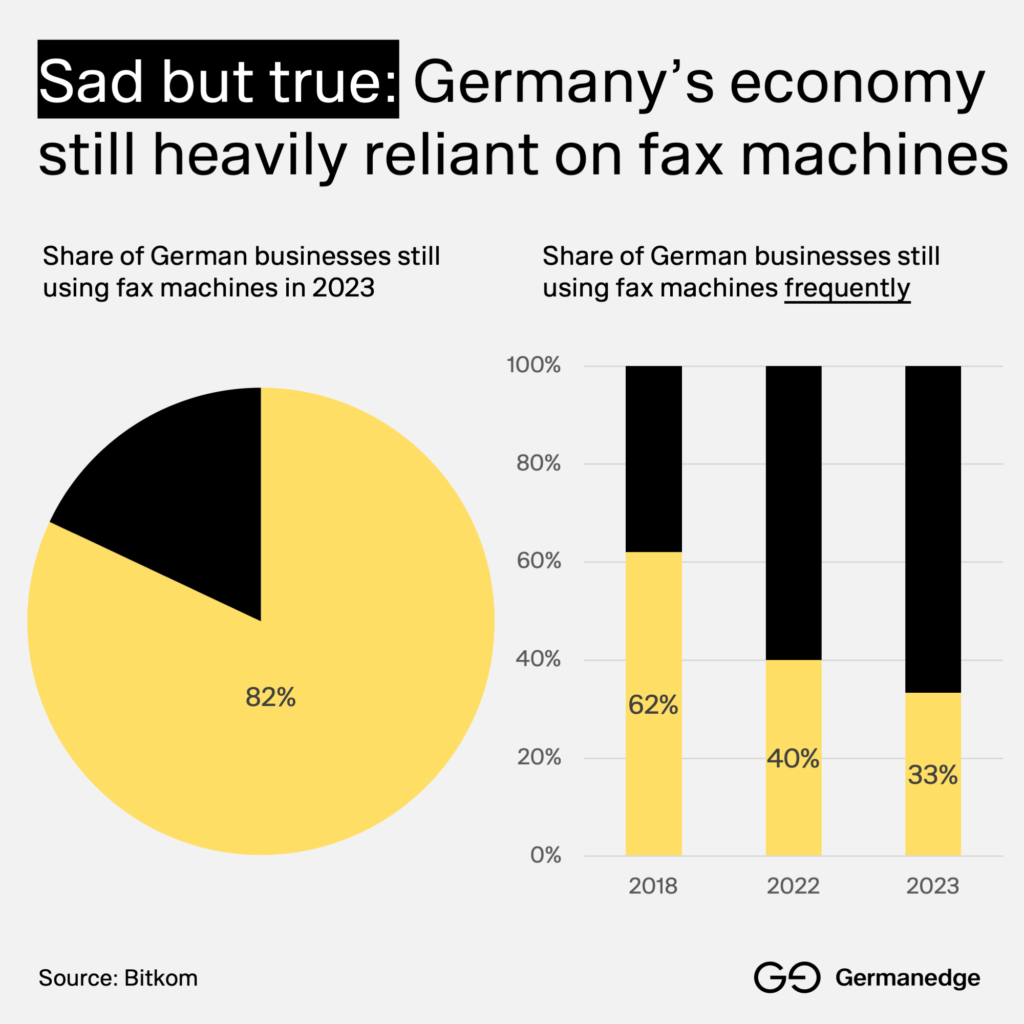

This reliance on fax machines isn’t confined to political offices.

A significant portion of German businesses and public services are still clinging to these outdated communication tools. According to a survey by Bitkom, the German digital advocacy group, a staggering 82% of German companies still used fax machines in 2023, with a third using them “frequently.”

The key question is: How can companies effectively implement the LkSG when supplier relationships and internal processes are still predominantly managed with pen, paper, and fax machines?

To meet the demands of modern compliance, we must urgently address our fundamental digital shortcomings.

For the German economy and its digital transformation, it is now or never.

We must break free from the chains of outdated routines and embrace the innovations that will drive us forward into the future.

The Call for Shock Digitalization

The time for incremental digital advancements has long passed. Germany, a nation long known for its precision and reliability, must adopt shock digitization now!

This radical approach emphasizes the necessity for swift, comprehensive, and radical digital transformation across all sectors of our economy.

- Shock digitization is not about making small, cautious steps forward; it’s about making bold leaps into the future.

- It’s about recognizing that our current pace of digital readiness is not enough to keep us competitive on the global stage.

- We need a mindset shift that values speed and agility over tradition and security.

We must overhaul our systems now, implementing advanced technologies like AI, IoT, blockchain, and cloud computing to revolutionize our production processes and supply chains. This rapid transformation will enable us to increase efficiency, reduce costs, and regain our competitive edge, for example, by building the most sustainable and ethical supply chains in the world.

Shock digitization requires a collective effort from all stakeholders – businesses, government, and society at large. It demands a willingness to take risks, experiment, and sometimes fail. But more importantly, it requires a commitment to learning and adapting quickly. The rewards of such an approach are immense: a more innovative economy, a more dynamic society, and a stronger global presence.

The Digital Factory as Germany’s North Star

At Germanedge, we are ready to lead this charge together with our customers in the industrial and manufacturing sectors. Our belief in the power of shock digitalization, especially when it comes to the future of factories, couldn’t be greater.

The pressure to shock digitize is greater than ever before, because those companies avoiding this path will fall behind faster than ever.

So, we need a clear plan for shock digitalization.

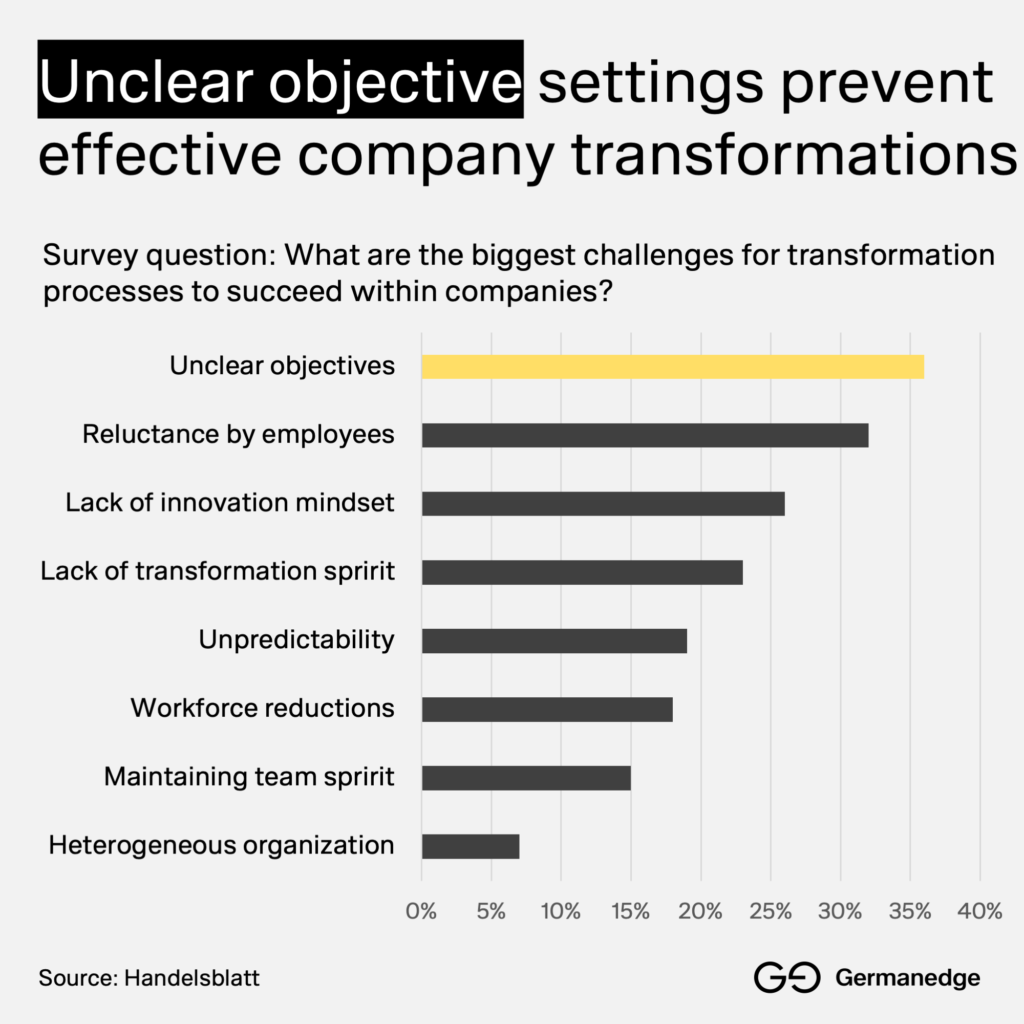

Successfully initiating a company transformation requires a clear and compelling objective. Unfortunately, many transformation initiatives in Germany fail because they lack such a goal.

As the CEO of Germanedge, I believe the primary objective for German companies on their shock digitalization journey should be to increase speed and agility.

- Speed in executing new innovations means that companies can quickly develop, test, and launch new products and services. This rapid cycle of innovation allows businesses to stay ahead of their competitors and consistently meet evolving customer demands.

- Agility, on the other hand, is about swiftly adapting to market changes. Whether responding to new regulations like the LkSG, shifts in consumer preferences, or disruptions in the supply chain, agility enables companies to pivot and adjust their strategies effectively.

Both of these elements are more important than ever. Here is why.

The No-Code Movement, Powered by GenAI

One critical factor drives the urgency of shock digitalization more than ever: the integration of GenAI and the no-code movement in product development. This convergence has revolutionized how quickly and efficiently businesses can innovate.

The no-code movement, which allows for the creation of software applications without the need for extensive coding knowledge, has dramatically increased the speed of software development. No-code platforms enable rapid prototyping, reduce costs, and democratize the development process, allowing businesses to respond to market demands swiftly and allocate resources more efficiently.

In simple words: Applications that once took weeks or months to develop can now be created in days or even hours.

The integration of Generative AI (GenAI) into no-code tools has further accelerated this trend. By allowing natural language prompts to generate code and automate workflows, these technologies reduce the need for technical expertise, making software development more accessible and efficient, even for non-technical users.

The business impact of this movement is profound:

- Forrester found that low-code/no-code development helps developers create cloud-native applications more than 10 times faster with 70% fewer resources.

- This efficiency is partly due to smaller teams being required. A typical no-code development team for a medium-sized project consists of fewer than five people, compared to up to ten for traditional development, significantly reducing labor costs.

- Gartner predicts that by 2027, 70% of professional developers will use AI-powered coding tools, up from less than 10% today. This clearly indicates a significant shift towards AI-driven development practices.

Leveraging Speed for LkSG Compliance

For companies governed by regulations like the LkSG, the implications are clear. To meet stringent compliance requirements and adapt to new regulations quickly, they must leverage these advanced digital tools. No-code platforms can be instrumental in building applications that enhance supply chain visibility and ensure compliance with the LkSG.

- For instance, companies can develop custom dashboards that track and monitor every step of their supply chain in real time. Such dashboards can integrate various data sources, providing a comprehensive overview of supplier activities and highlighting potential risks.

- Automated reporting tools can be created to generate compliance reports effortlessly, ensuring that all necessary documentation is up-to-date and readily available for audits.

- Furthermore, no-code tools can facilitate the creation of automated alert systems that notify companies of any deviations from compliance standards, allowing for immediate corrective action.

This level of visibility and responsiveness is a must for adhering to the LkSG and similar standards in the future, which will only become more stringent and common going forward.

The key message is clear: companies that do not embrace shock digitalization will soon find themselves unable to meet regulatory standards and compete with digitally advanced competitors.