Enough with the complaining.

Yes, the German economy is struggling. Yes, 2024 was another year wasted on political deadlock. Yes, analysts are painting a picture of ongoing decline.

And yes, we’ve all seen the “sick man of Europe” headlines on repeat.

But whining won’t fix anything.

Reality is what it is. The only question that matters: What are we going to do about it?

The good news? It’s not too late to turn things around. But there’s only one way forward. And if you’ve been following me over the past few months, you know exactly what I’m about to say: Shock Digitalization.

No more half-hearted digital initiatives. No more waiting for the “perfect” conditions.

We need a radical acceleration of digital transformation—supercharging our factories, supply chains, and industrial backbone to be faster, more flexible, and more resilient.

The starting point? Courage.

Courage: From Thinkers to Makers!

For centuries, Germany has been the land of Dichter und Denker—poets and thinkers. But in today’s tech-driven industrial age, we must become the land of Doers and Makers.

We don’t lack the talent, the economic IQ, or the industrial resources. What we lack is the courage to build, to execute, to lead.

- The courage to break free from outdated structures that hold us back.

- The courage to prioritize action over endless analysis.

- The courage to fully commit to shock digitalization and the Digital Factory

And nowhere is this more evident than in our approach to digital transformation.

For too long, our national conversation around digitalization has focused on the effort it requires rather than the opportunities it unlocks.

We measure digitalization by what it costs instead of what it creates.

Meanwhile, true makers focus on the outcome—speed, flexibility, resilience, competitive advantage.

Germany has always been a nation of problem solvers and world-class engineers. Now, it’s time to channel that legacy into building the industries of the future.

Makers over Thinkers. Action over debate. The shift has to start right now!

The Ingredients for Our Industrial Comeback

So from here on out, let’s shift the conversation.

Digital transformation isn’t just an efficiency upgrade—it’s a fundamental rewiring of how industries operate, compete, and grow. And when done right, it’s the most powerful economic accelerator we have.

At its core, the impact of digital transformation can be distilled into three game-changing attributes: Speed, Flexibility, and Resilience.

Together, these pillars will create enormous momentum. They will unlock the economic flow needed to get Germany back on track and put us back in the driver’s seat of industrial innovation.venues for growth and business model innovation.

1. Speed: Move Fast or Fade Away!

In today’s industrial landscape, speed is survival. Move fast, or risk getting left behind.

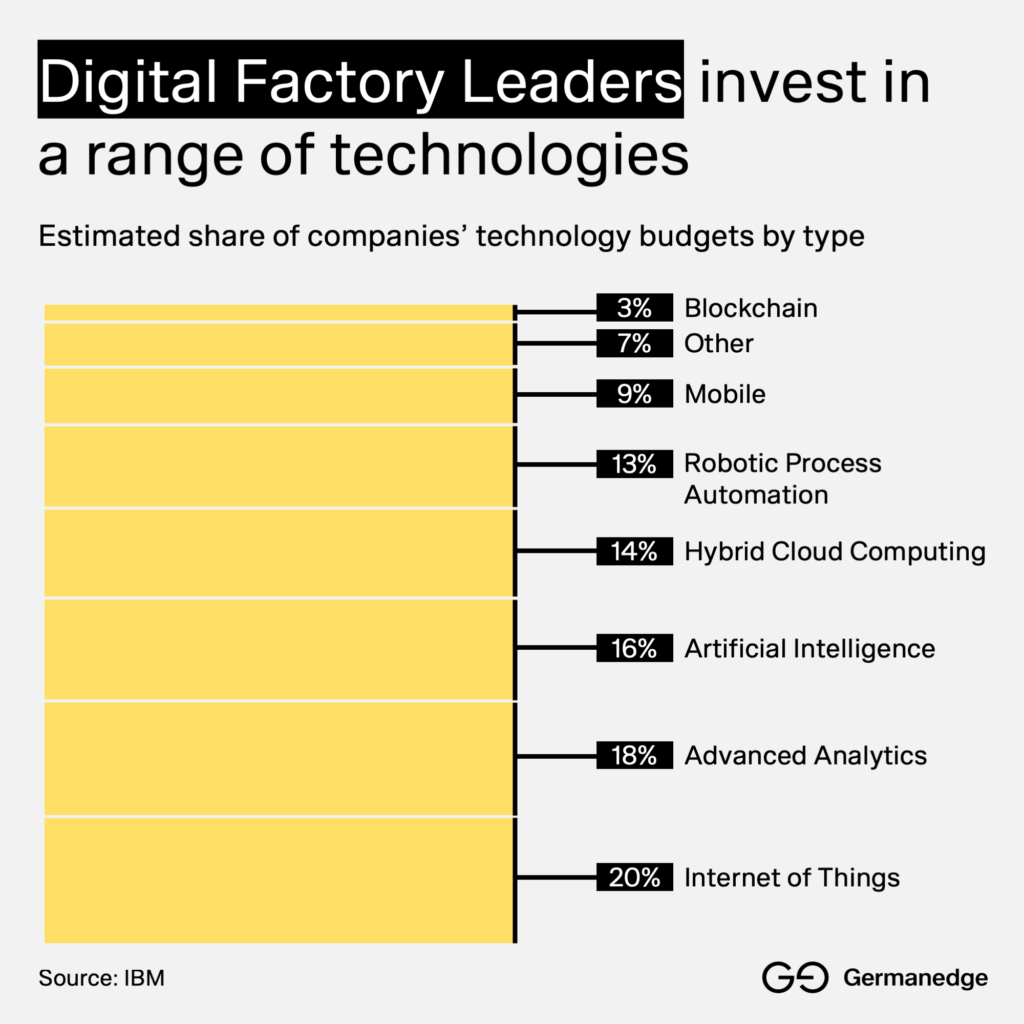

Speed is what separates industry leaders from laggards—and it’s why embracing Industry 4.0 technologies like AI, IoT, Advanced Analytics, the Cloud, and Big Data is no longer optional.

These innovations fuel the Digital Factory—where machines, processes, and systems are seamlessly connected through advanced sensors, IoT networks, and the cloud.

This connectivity redefines how fast companies can operate.

The ability to move faster—whether it’s slashing time-to-market, optimizing production, or adapting to shifting customer demand—is the defining competitive edge of the future.

- According to IBM research, digital industry leaders cut their time-to-market by an average of 62 days. And in today’s world, 62 days is an eternity.

- For comparison: China’s DeepSeek AI model R1—which just sent shockwaves through the global tech industry—was trained in only 55 days.

That’s the power of speed.

And that’s why digital transformation isn’t a cost—it’s the only investment that guarantees you a future.

At Germanedge, we’ve seen firsthand how speed transforms industrial performance:

- A global industrial engineering and manufacturing leader implemented our ORSOFT Manufacturing Workbench and, within just three months, improved productivity output by 10% while reducing throughput time by 20%—unlocking a new level of operational efficiency.

- One of our automotive OEM clients leveraged our Quality Management software solutions to cut manual quality control efforts by more than 80%, thanks to real-time digital tracking and AI-powered production analysis. The result? Millions in annual cost savings—and a production process that now moves at a speed and precision their competitors can’t match.

2. Flexibility: Thrive in Uncertainty or Break Under Pressure!

From pandemics and supply chain breakdowns to geopolitical conflicts and trade wars, recent years have proven one thing:

Flexibility is a survival skill.

In today’s volatile market, the ability to pivot, adapt, and respond to uncertainty is what separates thriving companies from those left behind.

Nowhere is this more critical than in factory operations.

Digital transformation gives manufacturers the ability to adjust production, reconfigure supply chains, and modify product lines with remarkable speed—turning disruption into a competitive advantage.

- Case in point: Manufacturers with Smart Supply Chains—powered by AI, IoT, and cloud technologies—consistently outperform their peers in times of uncertainty.

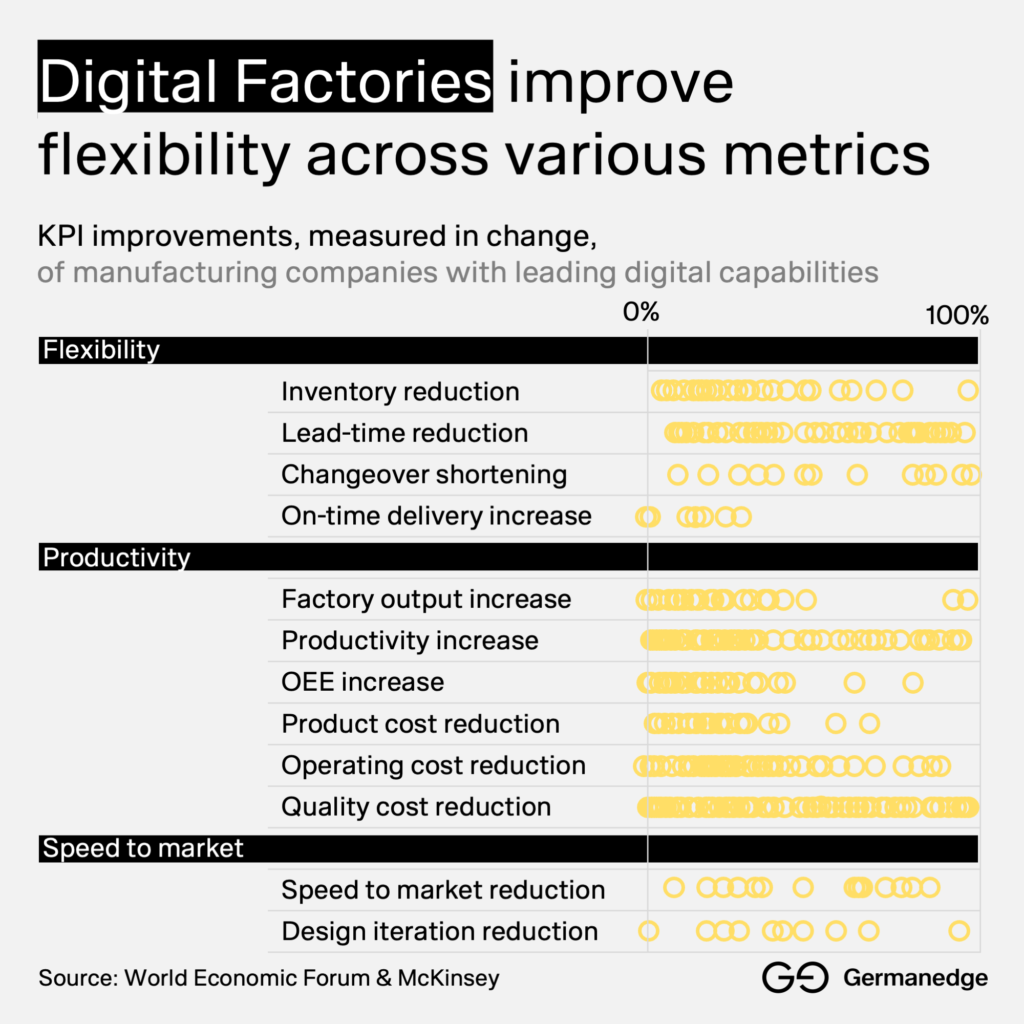

- According to the WEF and McKinsey, digital leaders in manufacturing achieve superior flexibility KPIs—from inventory reduction to lead-time optimization and on-time delivery.

And yet, in Germany, flexibility is still misunderstood.

Flexibility doesn’t mean abandoning structure—it means redefining it.

It’s about building modular, agile operations, powered by digital technologies, that allow companies to adapt without sacrificing quality or control.

The companies that master this will own the future.

3. The Resilience Imperative: Strength in Crisis

Resilience is the third indispensable outcome of digital transformation—and in today’s world, it’s the difference between thriving and collapsing in an era of constant disruption.

Why?

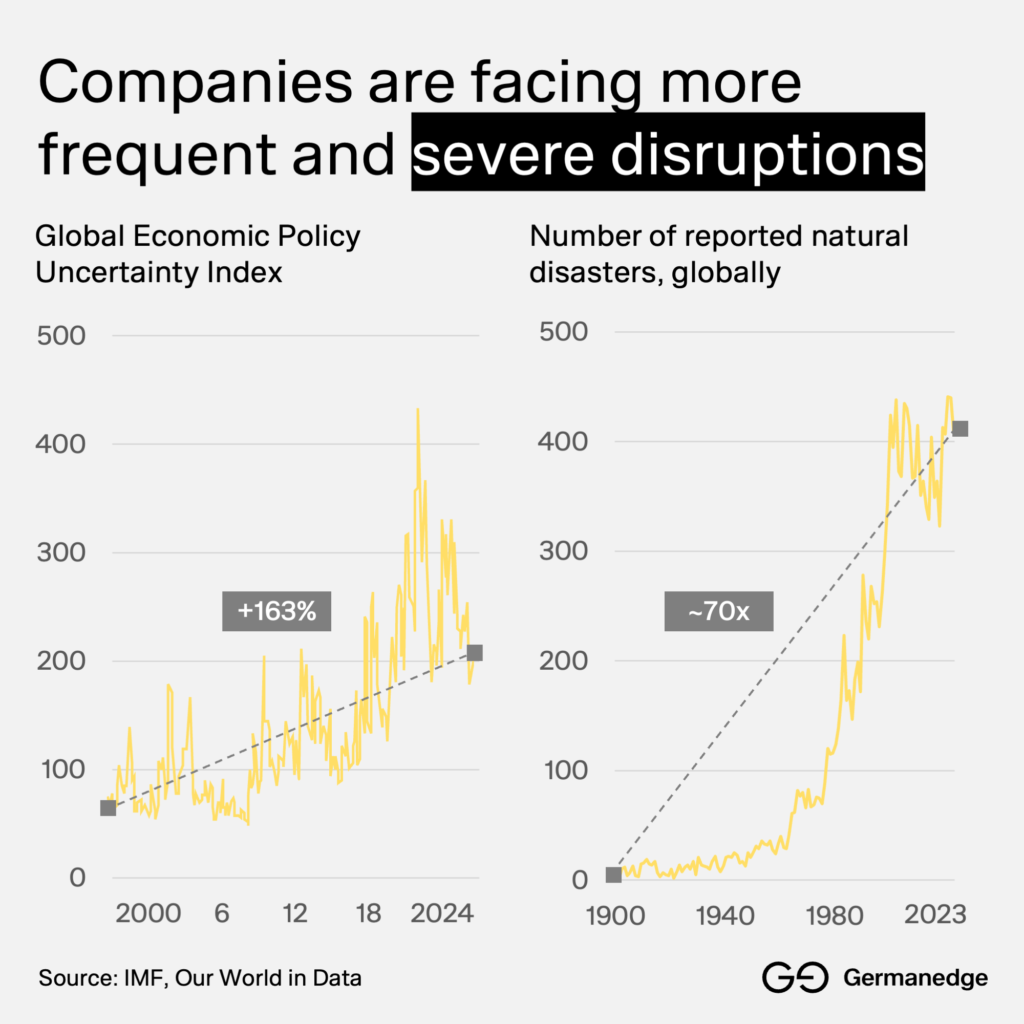

Because crises aren’t slowing down.

Economic shocks, supply chain breakdowns, cyberattacks, climate disruptions—they’re happening more often and with less warning.

Resilience is what allows companies to absorb these shocks, recover quickly, and emerge stronger—but only if they’re digitally prepared.

In the manufacturing sector, resilience takes many forms:

- Predictive Analytics – Digital tools detect supply chain risks before they escalate, allowing companies to pivot before disruptions occur.

- Smart Supply Chains – Full visibility along the entire value chain helps foresee bottlenecks, adjust sourcing strategies, and optimize production planning in real time.

- Cyber Security – As factories become digital, cyber threats multiply. The most resilient companies implement advanced security measures to safeguard operations and ensure uninterrupted business continuity.

Yet IT resilience is still an afterthought in too many organizations.

Too often, leaders only recognize its importance after disaster has already struck.

That mindset has to change. Resilience must be built in—not bolted on.

The Flow Economy: From Thinkers to Makers

Speed, flexibility, and resilience are the foundation of a thriving industrial economy.

Together, they create flow—an industrial system that is agile, competitive, and built for the future. And let’s be clear: this is the only path forward. We can keep analyzing, debating, and over-engineering solutions, or we can start building them.

But the world isn’t waiting. AI is being deployed at scale. Factories are becoming fully digital. Markets are shifting at lightning speed. Germany cannot afford to be left behind.

We have the industrial DNA to lead. What we now need is action.

At Germanedge, we don’t just talk about digital transformation—we make it happen. Through our Digital Factory-as-a-Service, we equip industrial players with the tools to accelerate, adapt, and stay ahead—with the courage to lead, not follow.