How Corona influences the factory of the future

When a “must” turns into a “must”, as is well known, things often develop faster than one could ever have expected. The fact that the future of industry will be digital is nothing new – and yet in many factories it is not yet a reality.

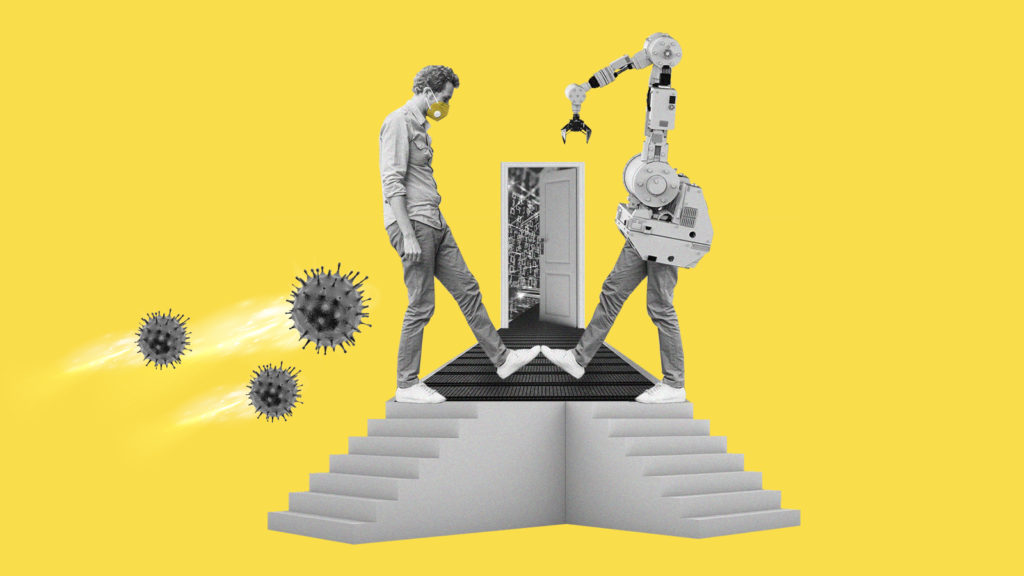

The coronavirus is accelerating digitalization. But as almost always, this is associated with both opportunities and risks.

Flexible automation as a way to go

Classic automation is primarily concerned with mechanical movements. A proper digitization approach, on the other hand, enables the automation of information flows and decision-making processes.

By merging flexible IT and classic automation, processes can be automated flexibly and networked consistently. People and machines act intelligently in a flow from the beginning to the end of the production process. After all, what good is the best machine with the highest degree of automation if the supply chain gets stuck and comes to a standstill?

The power lies in the beginning

The Corona crisis has shown how rigid many production companies still are. Astonishingly, when you consider how quickly new processes can be setup and the right foundations can been laid. And these are quite simple: digitization strategy, platform with a modular approach and the right mindset.

Because despite all the digitization wishes, one thing must not be forgotten: Digitization is only successful if it is actionable. With an IT infrastructure that accesses various tools, is programmed in a highly complex way and considers each individual component of production on its own, there is no solid foundation for a long-term business model.

“Not my business“

One of the biggest hurdles to digitization is often the company’s own employees. Be it because this topic is seen as detached from their own job description or because the fear of something new or that will result in change: a strategic approach is needed.

Of course, digitization is changing everyday work – not only in the factory of the future. But this is nothing to fear. The future of the factory is not only digital, but also human. If done correctly, the use of new tools will be easy, intuitive and valuable for the employee. The goal must be to generate a level of cooperation between man and machine – and not just to rely on coexistence.

Act now for tomorrow

Corona has shown us all how quickly things can change. And that it can be too late to start asking yourself the key questions until the crisis is over. Only those who take the first steps today can go further tomorrow.

The future of production is no coincidence. Even if crises such as Corona come upon us unexpectedly, they shake especially those who have not yet taken action.

So the greatest opportunity in the Corona crisis for production is the wake-up call that comes with it: companies must actively shape their future. And that also means planning, trying, learning and developing step by step. Right up to their own definition of the factory of the future.

Would you like to read more about the topics concerning the future of production? Then take a look here!