Production Scheduling Software | Worst-Case Scenario: Unable to Deliver!

Software-aided production scheduling has never been easier and more transparent

We all may know this annoying situation in production scheduling: An unplanned order is received from a priority customer. The lead time is incredibly short. And production is running at full capacity anyway. On top of that, the most experienced colleague has called in sick.

Our production scheduling software helps you to avoid the worst case: unable to deliver. Because software-aided production planning has been part of our entire DNA for more than 30 years.

Advantages of our production scheduling software:

Visit GermanedgeNOW - our Industrial Application Store

Would you like to test our Digital Factory Scheduling immediately and get to know the various functions? Then GermanedgeNOW offers you the opportunity to test the DFS immediately, free of charge and without obligation for 30 days.

This will bring order to the document chaos and shorten your “time-to-business-impact” and thus immediately increase your “return on investment” (ROI), as you can use the software immediately.

Architecture of the production planning software based on our modular platform Edge.One

Functions of our production planning software:

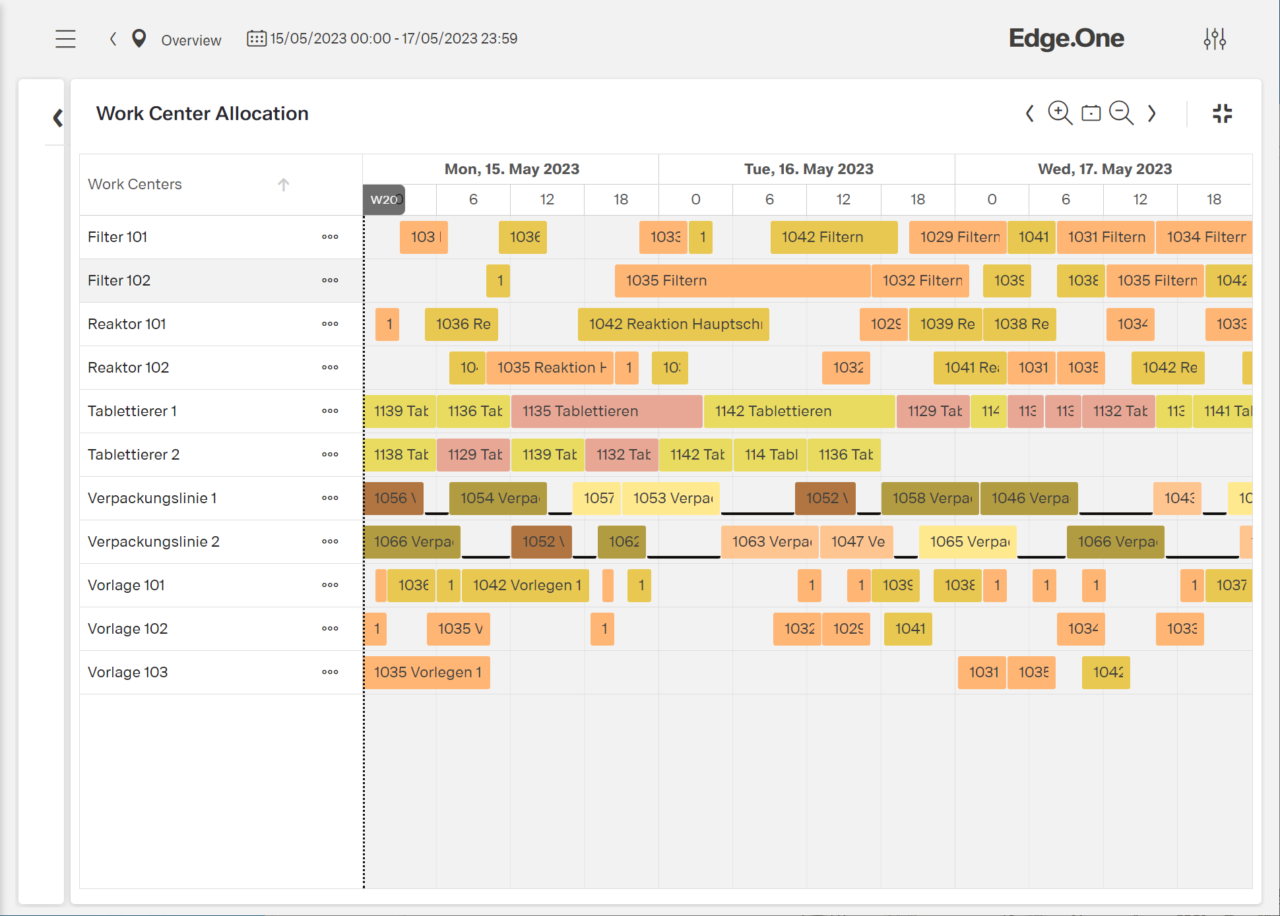

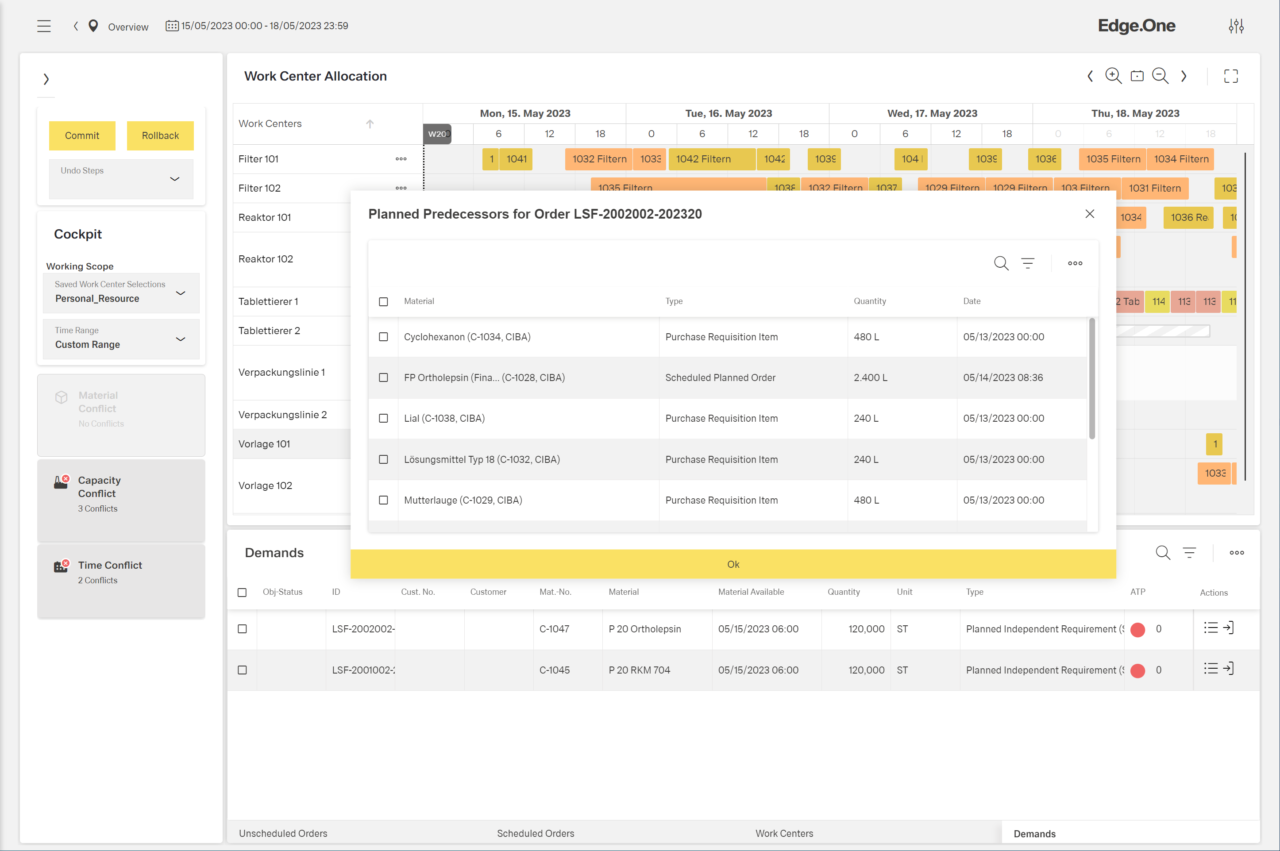

Gantt charts provide users an overview into the overall situation in production planning:

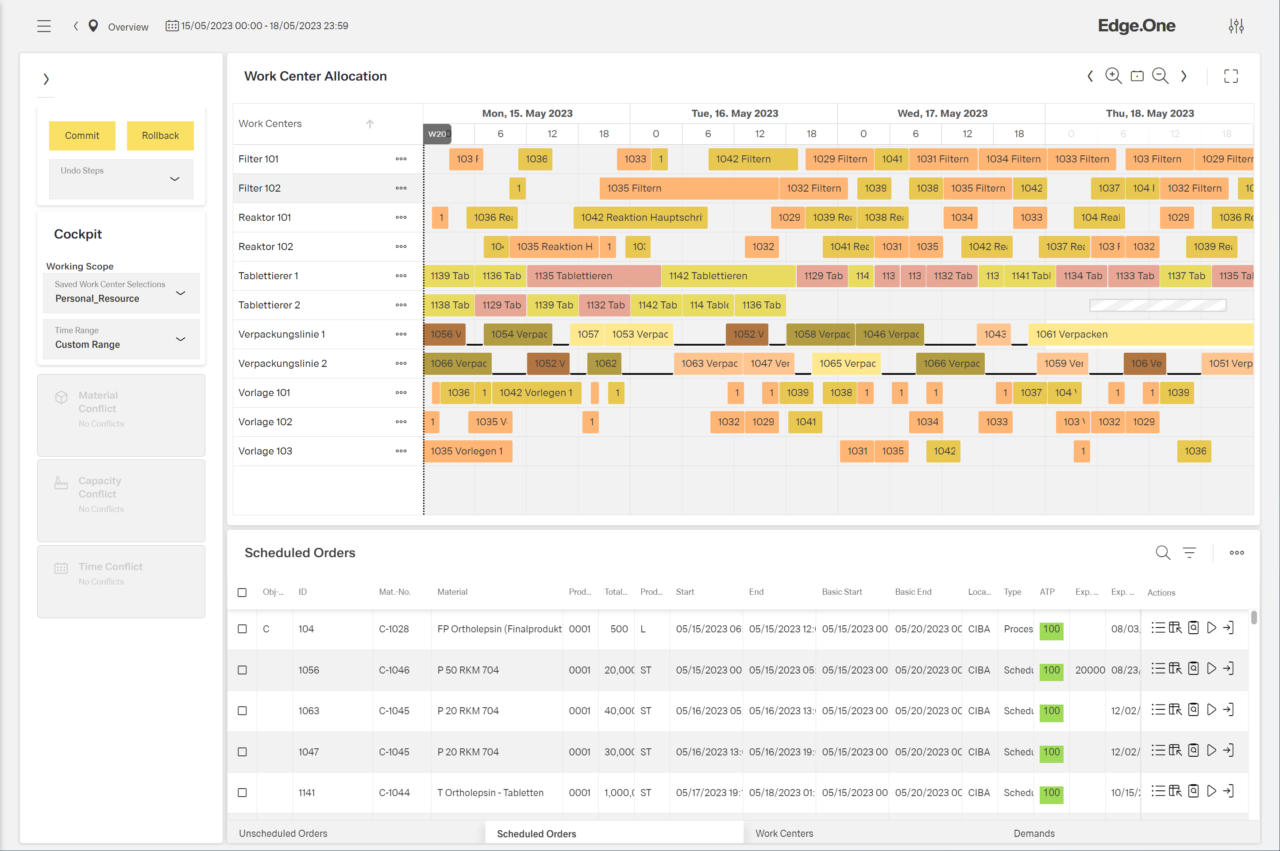

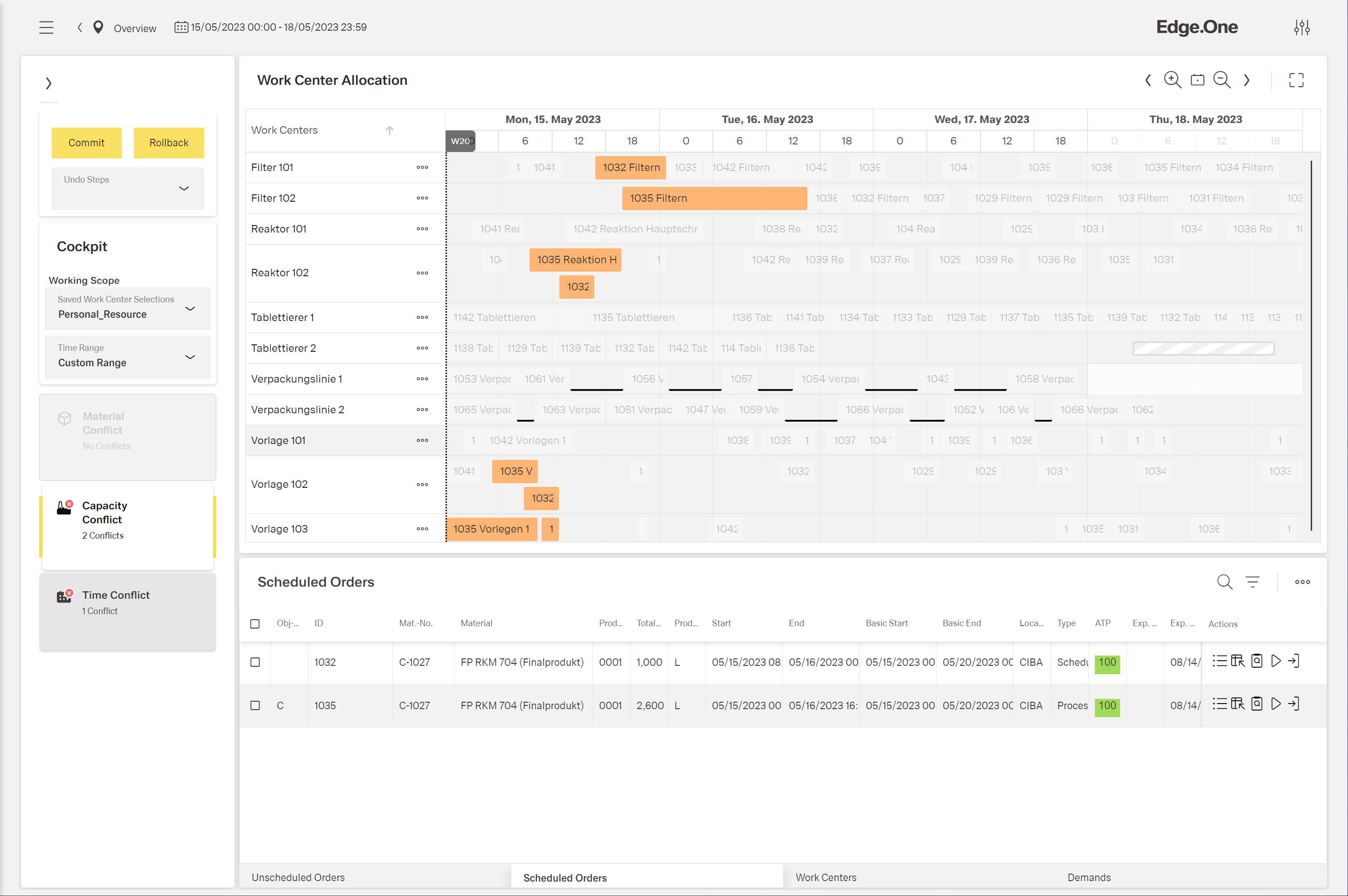

Based on our user-friendly UI/UX design, the production planning software allows a straightforward guiding through the entire planning situation. Modern dashboards deploy aggregated material, capacity, time and demand conflicts and display them in concise windows. All existing conflicts can quickly be resolved with the help of simulations. Accordingly, production plans can be adjusted at any time by drag & drop or automatically. Thus, they can be aligned to key figures, and ad-hoc adjustments can be made. On top of that, the state-of-the-art web application allows you to use the software in all common web browsers. Hence, all information can be used both on desktop PCs and on mobile devices.

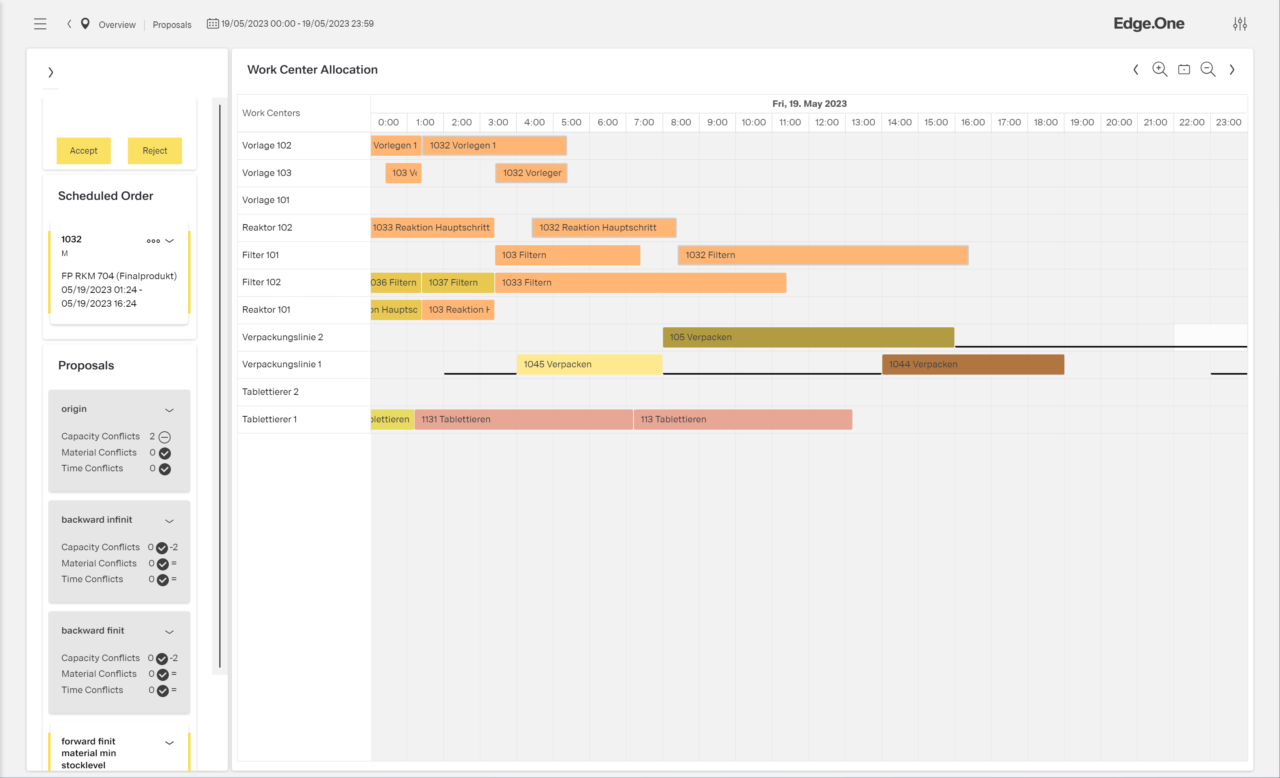

What if simulations: Master your optimal production plan with ease:

ERP systems and decentralised Excel solutions quickly reach their limits in production planning. Actual data and potential risks from the supply chains cannot be reflected adequately. Thus, a plan B is hardly feasible. In contrast to that, our production scheduling software enables what if scenarios, allowing the early simulation of probable disruptions which may affect the planning run. Substantial incidents can therefore be considered at an early stage.

Artificial intelligence enables automatic planning:

Thanks to artificial intelligence, the production management software can run optimisation scenarios for material, capacity, time and demand conflicts, allowing the tool to create automatic planning proposals. Integrated algorithms help to find the best solution among all possible ones. This enables planners to implement key figure-optimised scheduling results. Possible targets may be the minimisation of inventory or production costs, or to keep guaranteed delivery dates.

Alert-driven conflict management! Always keep an eye on bottlenecks:

In production planning, it is crucial to quickly identify and resolve any conflicts that arise. In operational scheduling, conflicts are mostly triggered by bottlenecks in required materials, overloaded workstations, machines or plants, or by missed requirement dates. Alerts provide real-time information about potential issues and enable teams to take immediate actions. Production plans can then be adjusted accordingly at any time.

Multi-level monitoring and Available to Promise:

Available to Promise (ATP) is a powerful tool of our production scheduling software. During online-ATP, all pegged requirements and simulated objects are checked individually with regard to the availability of necessary materials. All material levels – from finished products and intermediate products to individual components and raw materials – are considered, even on a multilevel basis. The allocation to specific customer orders enables the transparent communication with the customer.

How to integrate our production scheduling software:

We orchestrate planning conflicts between Enterprise Resource Planning (ERP) and Manufacturing Execution System (MES)!

Our easy-to-implement cloud and SaaS-ready production scheduling software is the modern platform-based alternative to small, local, and isolated applications. The seamless horizontal and vertical integration into the upstream ERP system makes all the necessary data available – synchronously and in real-time at all times.

The production scheduling software is an integral part of our Manufacturing Operations Management (MOM) platform Edge.One. The platform combines multiple functions and acts as

- a modern PaaS hub,

- a software development kit (SDK) for new services and frontends,

- an app store of the Unified Production Workplace (UPW),

- an integral design system.

Production scheduling software: step-by-step intgration on your side:

- Contact us

- We provide a live demo of the software tool

- We discuss your individual requirements and aspects of the technical integration

- We support the integration and roll-out

What is a production scheduling software?

Definition production scheduling software

A production scheduling software helps to plan, coordinate and control the entire production process. The software tool helps to allocate resources such as labour, material and equipment, with focus on quantity, deadline and capacity. The implementation results in more efficient and cost-optimised production plans.

What tasks does a production scheduling software perform?

A production scheduling software is intended to manage planning and control tasks ranging between the central ERP and MES at shopfloor level.

The tasks of a production scheduling software are

- the creation of production plans

- the management of safety stocks,

- the allocation of resources,

- the tracking of production progress and

- the creation of performance reports.

In addition, a production scheduling software plays a central role in communicating within teams as well as between different departments, customers and suppliers. By providing a single point of truths, you can make decisions more easily, which in turn, results in raised operational efficiency.

What should a production planning software be able to do?

As often in reality, the answer is “It depends!”. It depends on the current situation in the company, on what the expectations are in regard of the introduction of a production planning software and on the complexity of the production or manufacturing processes itself. However, there are a number of minimum requirements a modern production planning software should include:

- Open interface for integration of peripheral systems

- Plug & Play integration into the central ERP system

- Support of manual and semi-automated production planning based on planning proposals

- Simulations of master and transaction data

- Creation of what if scenarios

- Provision an Available to Promise (ATP)

- Management of time and resource conflicts in line

- Drag & drop functionalities within Gantt charts

Who needs a production management software?

For every company in the manufacturing and process industry, production planning is critical. Because without an effective production, there are no deliverable products. And without products, there is no turnover and no profit. Of course, the requirements for a production management software vary greatly depending on the customer and the industry. As a rule of thumb, the larger the company and the more complex the production processes and supply chain relationships, the more a production management software needs to be supplemented with Advanced Planning & Scheduling (APS) functionalities.

What’s the difference between Advanced Planning & Scheduling and production scheduling?

Production planning is divided into different planning horizons – strategic, tactical and operational. Depending on the industry and the production process, the time horizons may vary considerably. Advanced Planning & Scheduling (APS) often refers to the strategic-tactical planning, whereas production scheduling describes the operational, detailed scheduling process.

An APS software usually includes functions to manage advanced production plan and resource optimisation processes. APS systems may include the planning of production campaigns, the management of external production by contract companies, cross-plant planning and vendor-managed inventory, among others.

In contrast, a production scheduling software demonstrate its strengths in regard to the operational execution of the production plan. This kind of software facilitates the tracking of material flows and labour utilisation, as well as the provision of real-time feedback on production status.

However, the transition of a production scheduling software and APS is fluid. In terms of an integrated end-to-end approach, all systems should be linked and communicate with each other. An integration into the upstream ERP is also mandatory.

Get in touch!

Would you like to know more about Digital Factory Scheduling? Please write to us using the contact form. My colleagues and I look forward to exchanging ideas with you.

Dominik Weggler

Head of Sales at Germanedge