Innovation is not a dream of the future

Digital solution for orchestrated production and laboratory planning

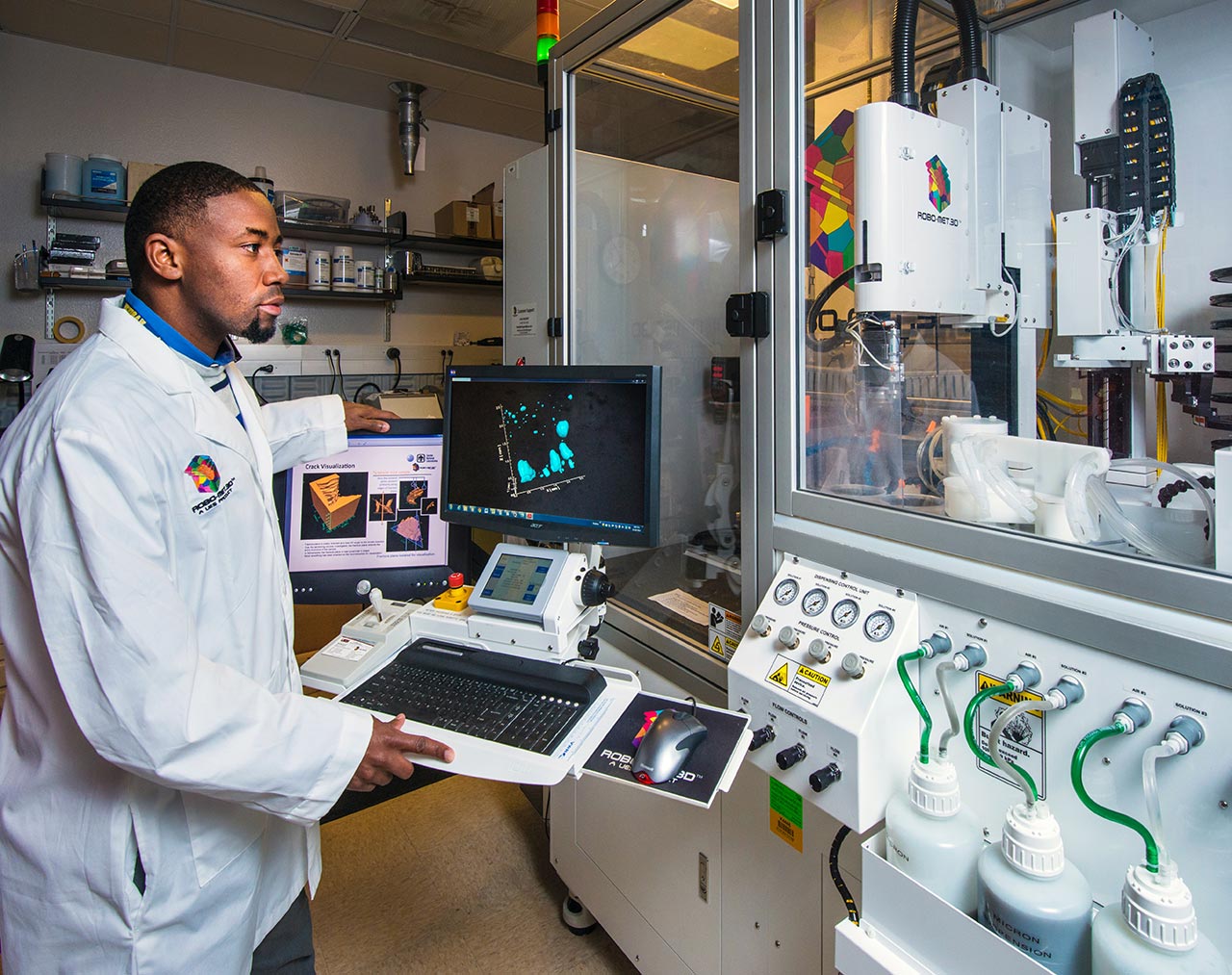

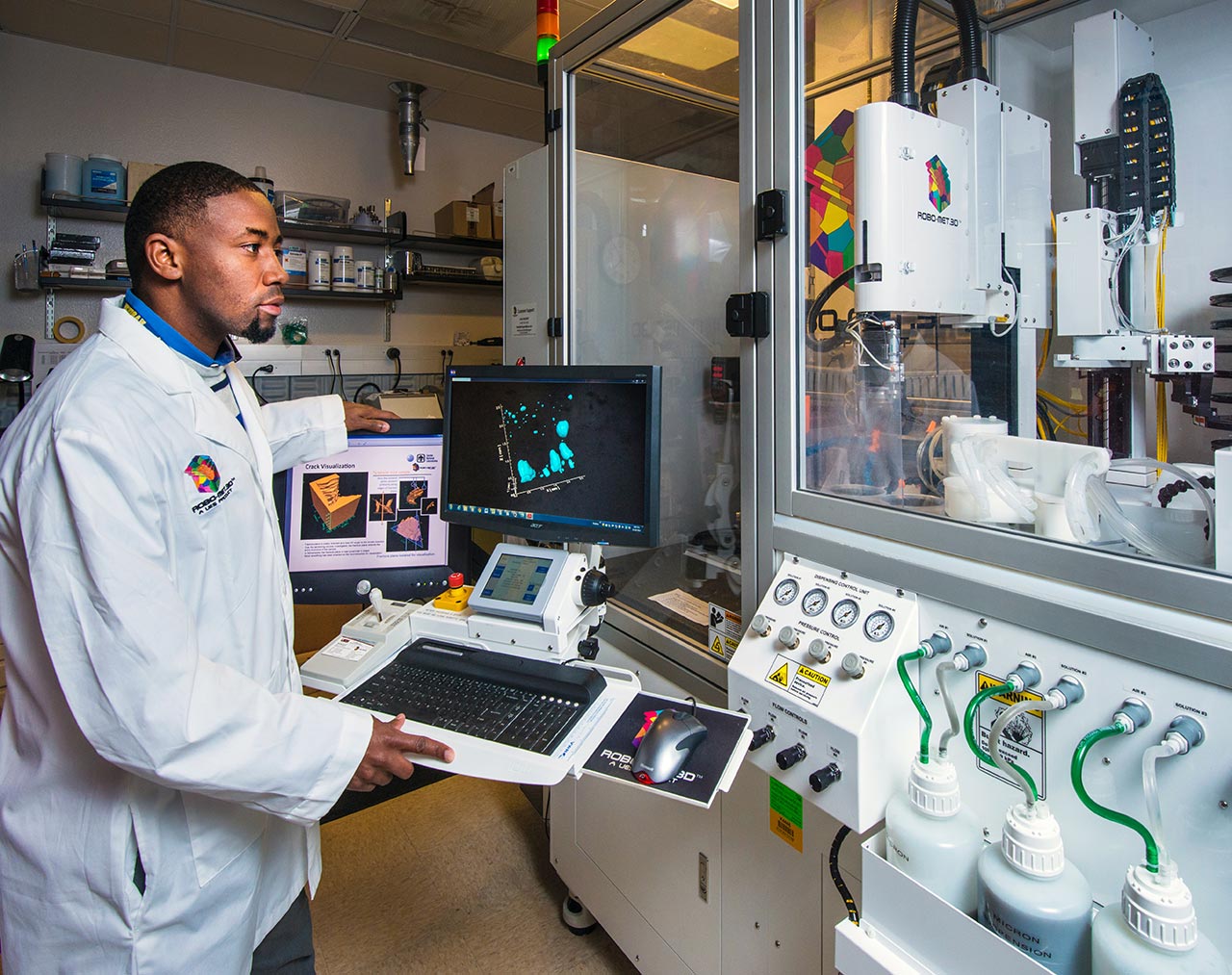

Innovation may not be predictable, but we all know the factors that inhibit innovation very well. These include a lack of resources, poor processes, overworked employees and a lack of communication that prevents results or creates duplicated work and isolated applications. In the laboratory environment in particular, one hundred percent accuracy and blind trust in the cooperation are essential – a good laboratory must work together like a first-class orchestra. Laboratory planning has a special role to play, especially with regard to quality management and efficiency optimization.

Realistic planning of laboratory processes

Production and laboratory planning processes are complex and can only be implemented with the help of suitable software solutions. Laboratory operators need a transparent and realistically plannable overview of the expected workload of their laboratories – whilst always taking quality management into account. Digital solutions for laboratory planning must include data from the MRP (Material Requirement Planning) run as well as forecasts of capacity utilization in terms of staff and timelines.

Germanedge offers sophisticated software for laboratory planning from the product provider ORSOFT.

Our Germanedge solution for production and laboratory planning

ORSOFT LabScheduling facilitates the planning of laboratory capacity utilization based on SAP master data and transaction data, such as inspection plans or inspection lots. To achieve this, the SAP inspection lots are supplemented by simulated inspection lots based on the SAP master data and customizing data. All of the inspection lots are then clearly displayed and arranged to provide a short and medium-term overview of the expected laboratory workload. All important factors of your laboratory and production environment can be simulated and tested before you finish planning.

Good planning is very simple: by assigning individual orders in the form of inspection lots, all employees know which tasks are still open and where the next stages of development lie at all times. It is no longer possible to imagine innovative production logistics without efficient laboratory and test field planning. The resources in your laboratory are thus optimally utilized and a high degree of efficiency is achieved while maintaining quality assurance. ORSOFT’s LabScheduling software is the digital baton for your test orchestra.

Integrated laboratory planning software for optimal processes and transparency

Our laboratory planning software can not only be combined with all common SCM-Software and the entire product range of your SAP ERP solutions within the framework of our Platform-as-a-Service (PaaS) solution EdgeOne; we also offer ORSOFT Manufacturing Workbench, an excellent tool for advanced planning and scheduling in the laboratory, which allows you to transfer results or products from your laboratories directly to the respective production environment. The solution also offers enhanced communication between production and laboratory, for example through automated warnings when scheduling changes lead to overlaps.

Optimized planning not only creates smooth processes and satisfied employees, but also saves money: overtime hours are expensive, and if they cannot be worked, it may result in delays in delivery – often resulting in financial loss and damage to your company’s reputation. A higher degree of transparency increases the personal responsibility for your employees and avoids costly personnel expenses – important key figures of your company’s success.

Get in touch!

Would you like to know more about our solutions? Then please write us using the contact form. My colleagues and I look forward to exchanging ideas with you.

Dominik Weggler

Head of Sales Germanedge