MES Software - Increase the efficiency of your production by 5%

Manufacturing Execution System

Manufacturing and production generate vast amounts of data that need to be collected and processed. A large number of orders quickly pile up in production and it is hardly possible to control these orders using paper slips. This approach creates inflexibility and is too slow in the rapidly growing dynamics of production in the context of digitalization.

With our Germanedge Manufacturing Execution System (MES), all resources and systems in production are intelligently networked. In addition to the SAP orders immediately integrated in the MES, you can use the software to plan the availability of your machines, resources and employees, which makes a decisive contribution to increasing your productivity. Our Germanedge MES software detects and rectifies faults immediately. The software can also be used to react quickly to new situations and production requirements. The MES software from Germanedge is a future-proof, cloud-based solution that creates a high degree of transparency through real-time data collection and thus sustainably increases efficiency in production.

Advantages of our Manufacturing Execution System

Get to know our use cases

Would you like to find out more about MES software based on a user example?

Then read our use case “Increase plant availability through central plant monitoring” and get to know the functions of the software even better. We also have further use cases on the topic of MES software and how you can integrate it efficiently into your production.

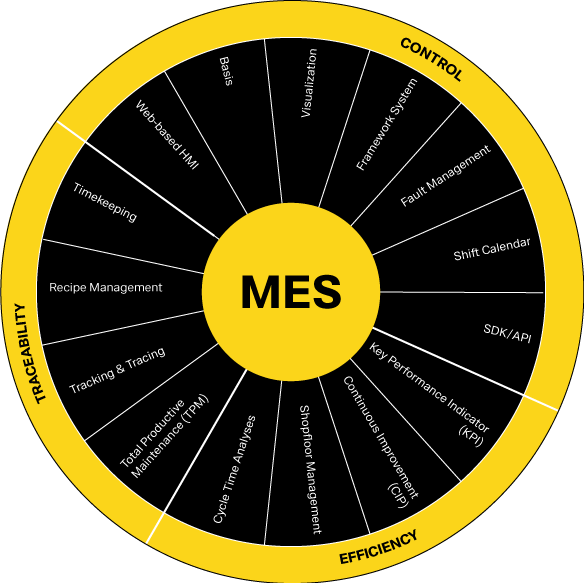

Functions of our MES software

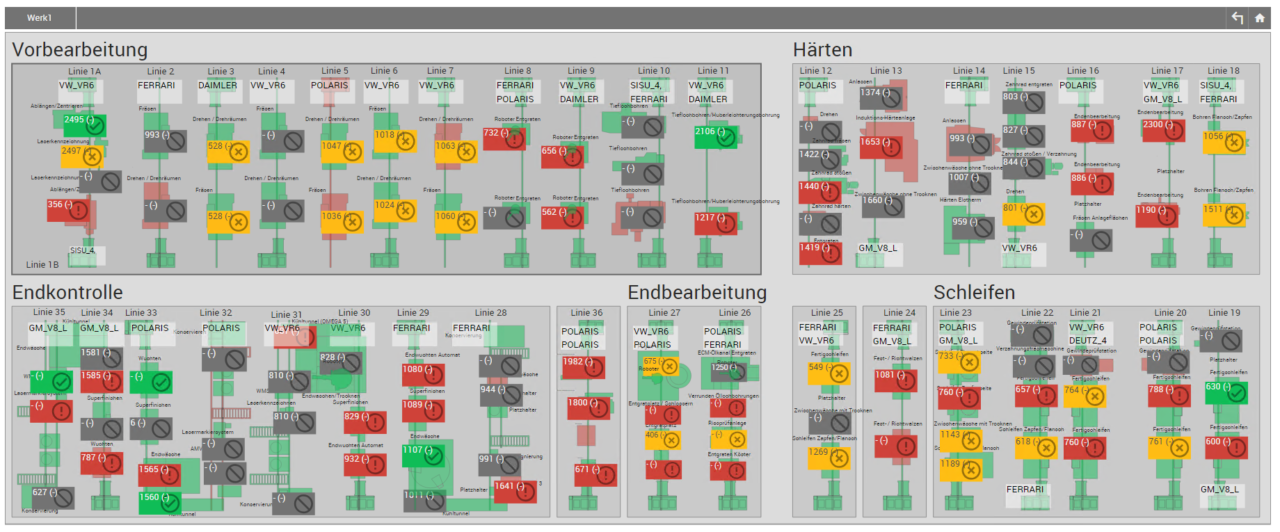

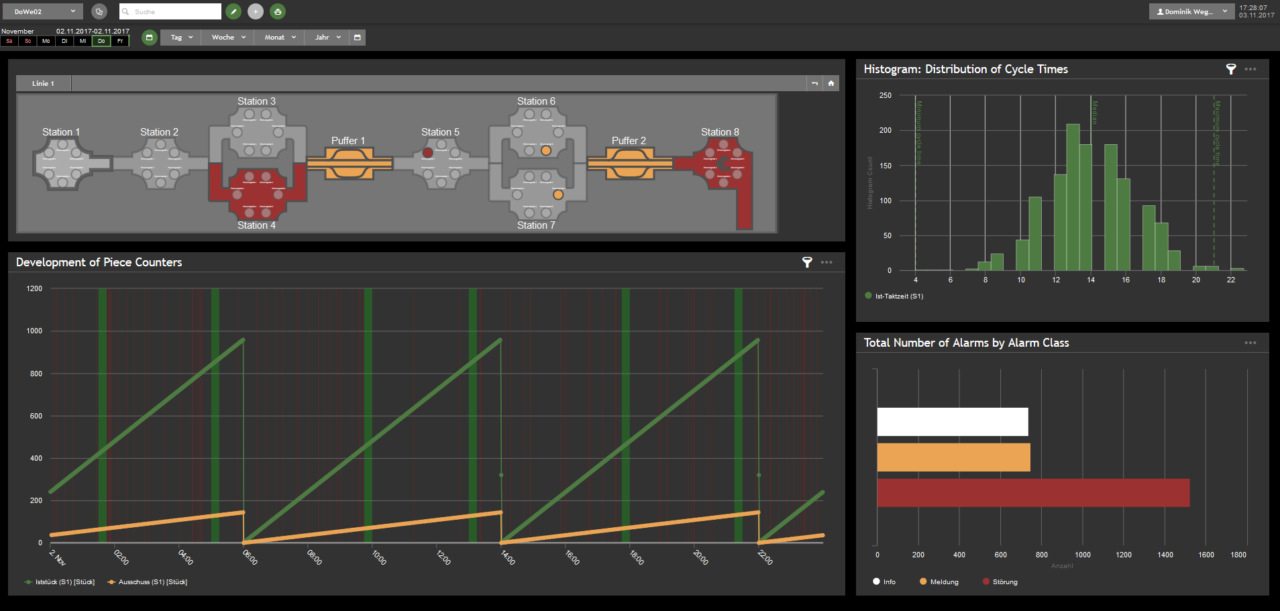

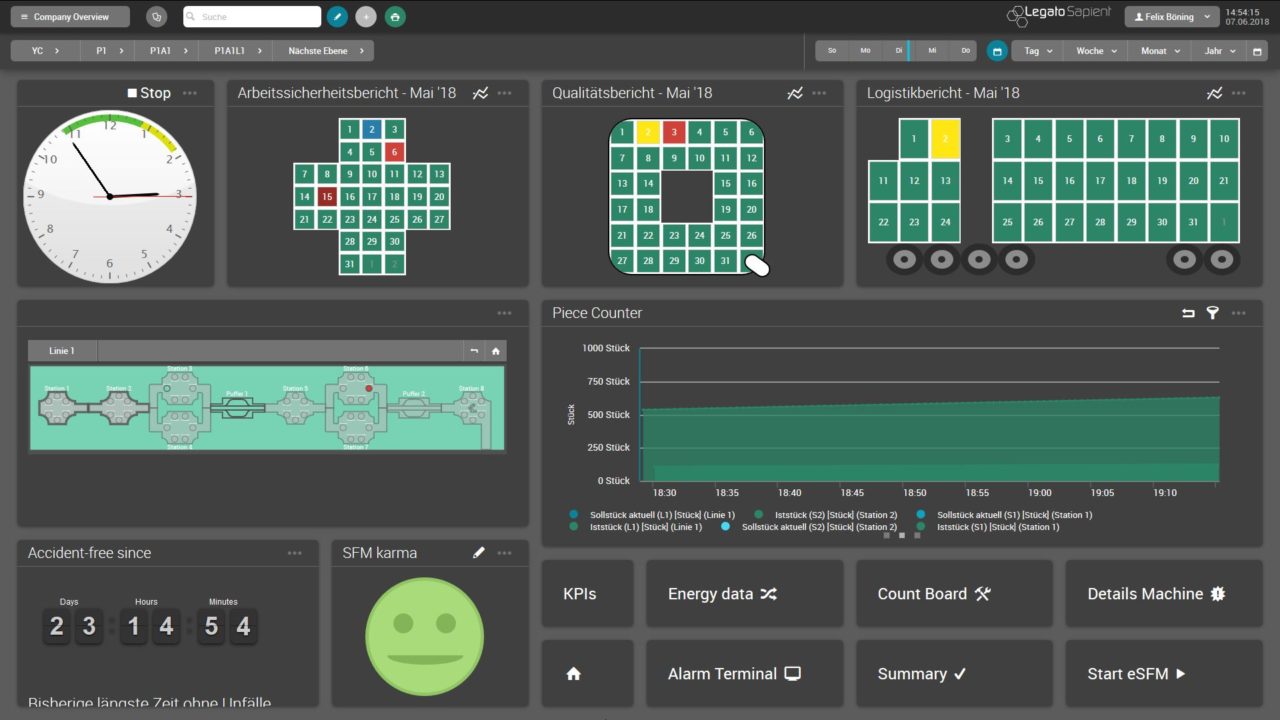

Production monitoring and control / monitoring of all machine data and messages

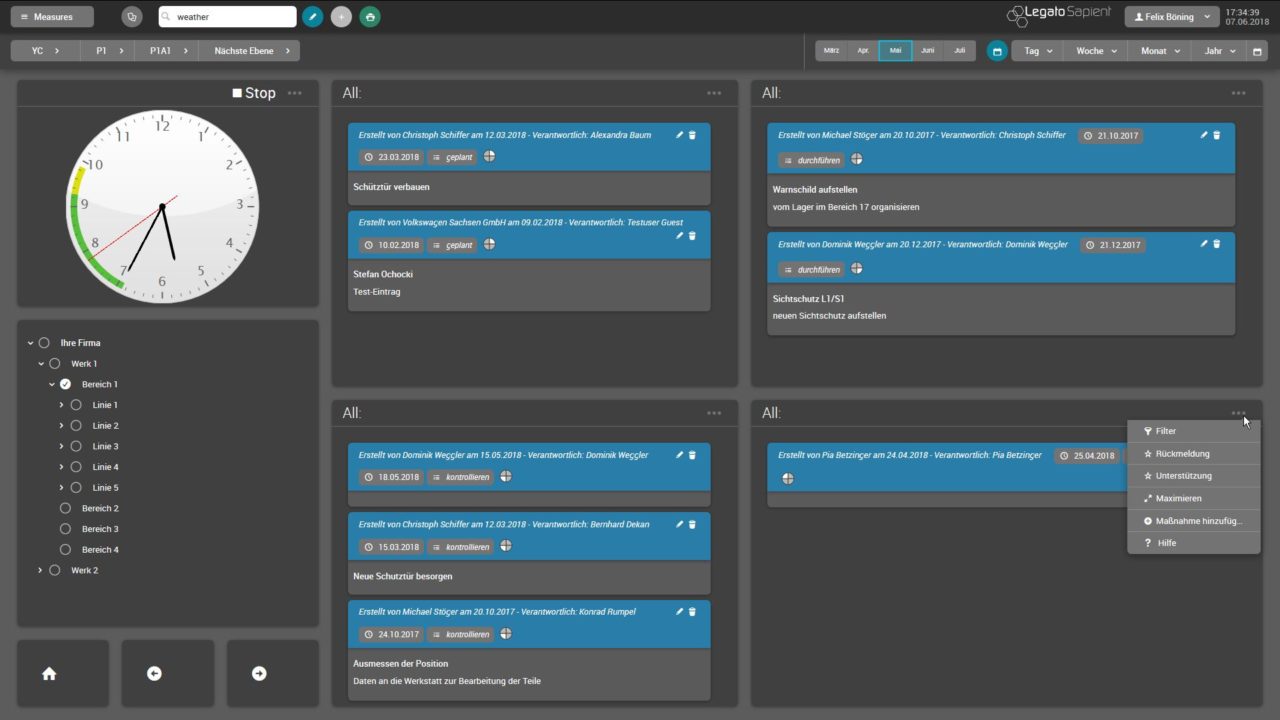

Germanedge’s MES software enables you to monitor and control your production process in real time. By automatically collecting and processing data from machines and sensors at store floor level, production performance can be tracked and decisions can be made quickly.

In the event of machine downtime, production is automatically informed so that an immediate response can be made. Based on the monitoring of your production, an overview of all relevant key figures can be provided and the OEE evaluated. This provides a transparent production overview and can be visualized graphically.

Traceability

The MES software enables seamless tracking of your products and components – throughout the entire manufacturing process. This is particularly important in industries with strict compliance requirements, such as the food and pharmaceutical industries. Components are seamlessly recorded and tracked during production and all events and production parameters are logged for each component.

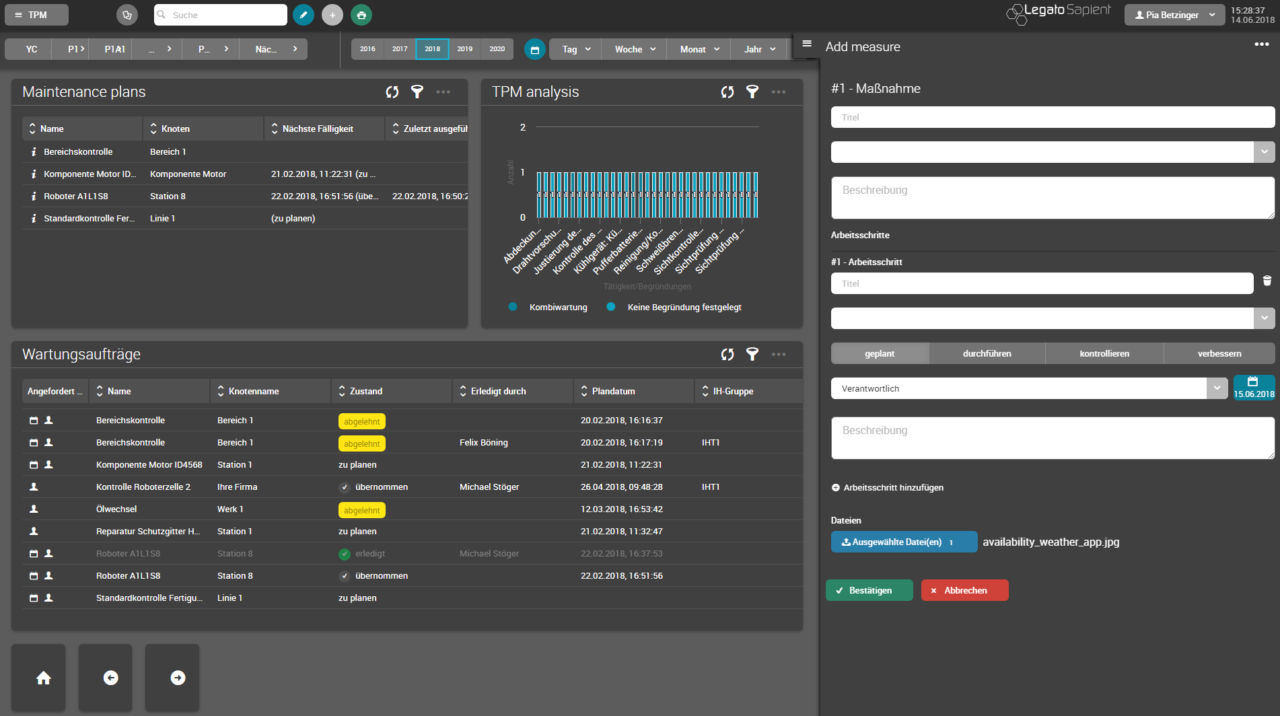

Total Productive Maintenance

With our Total Productive Maintenance Software, you can easily plan your production thanks to recurring machine maintenance. Maintenance triggering is controlled by time intervals and operating values, and the listed maintenance steps can be easily documented. You also have access to all the necessary maintenance documents and instructions.

Machine and production data acquisition (MDA/PDA)

Our module for machine and operating data acquisition enables a rapid response to faults with the help of regular online monitoring of real machine states without manual effort. Monitoring of tolerance and intervention limits provides automated alerting.

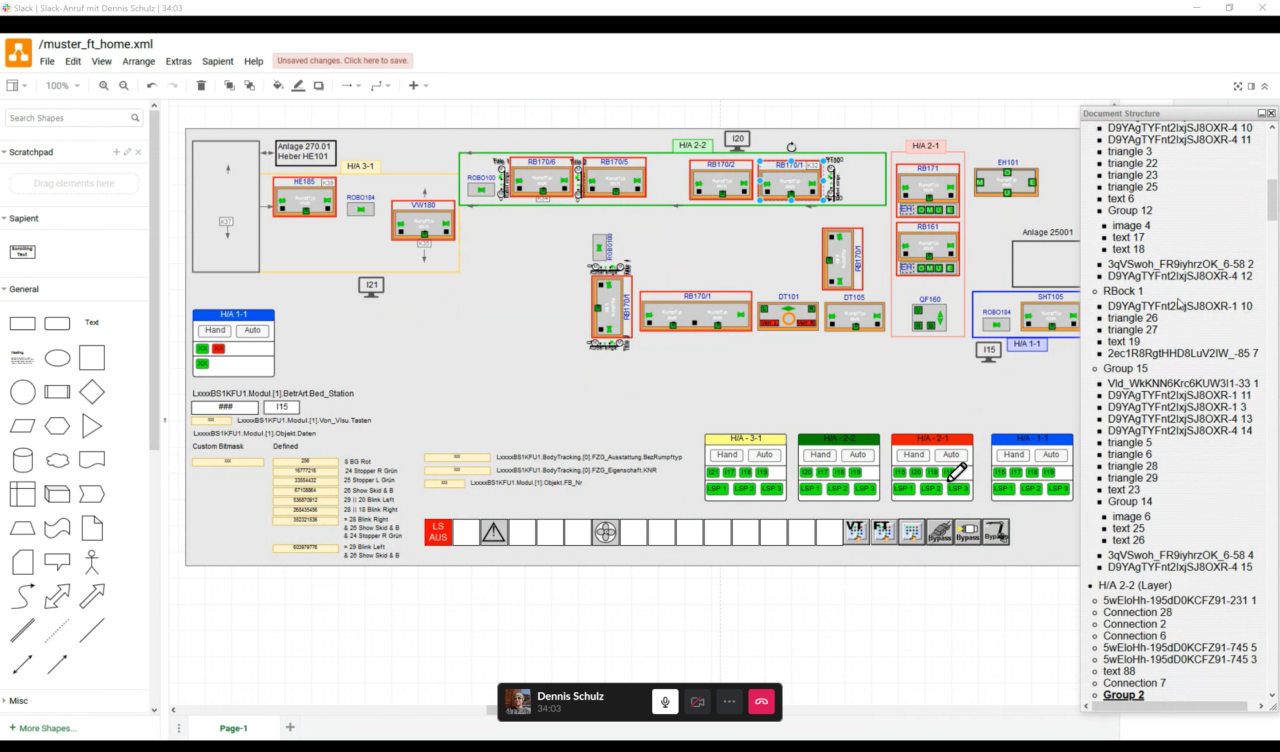

Human Machine Interface

Our Manufacturing Execution System (MES) offers integrated HMI software that allows you to visualize machine data directly in the browser. The cloud-based project planning environment makes it easy to create and centrally manage your visualization screens – flexibly, efficiently and specifically tailored to the requirements of production.

Find out more!

On demand Webinar on the topic of MES software - Only in German!

Sie sollten sich das jetzt zum Webinar anmelden, wenn …

- auch Sie eine schnelle Amortisation der Investition durch Kosteneinsparungen und gesteigerte Effizienz wollen

- Sie die Ausbringung Ihrer Produktion um mindestens 3% erhöhen wollen

- Sie durch schnellere Reaktionsfähigkeit bei Prozessabweichungen die Maschinenverfügbarkeit erhöhen und die Anlagenverfügbarkeit dank der Vermeidung von unproduktiven Zeiten steigern wollen

- auch Sie frühzeitig Abweichungen in Ihrem Produktionsprozess erkennen wollen

- Sie Informationen in Echtzeit bereitgestellt bekommen wollen

Who benefits from our Manufacturing Execution System?

Advantages for production/plant managers

As a production or plant manager, you are responsible for ensuring that production in the company runs smoothly. With our Germanedge MES software, you can ensure that the relevant key figures in production improve significantly and thus increase the output of your production.

Advantages for production line managers

If store floor management in production is carried out using paper-based paperwork, this means a lot of effort as well as cumbersome recording and no possibility of evaluating the data quickly and reliably. Our MES software enables you as a production line manager to measure production data so that measures can be designed sustainably and efficiency and transparency in production can be increased.

Wide range of options for integrating our MES software

Our MES software is designed as an application of our PaaS platform Edge.One. The modern framework acts as a central digital hub for all Germanedge and third-party applications. The goal: nothing less than the Digital Factory.

Our MES software allows the following integrations

Technology of our MES software

Designed for thousands of data sources in production:

Simple, fast and standardized connection to thousands of machine control systems

Control of all systems:

Delay-free, bidirectional exchange from and to the production level

Digital empowerment of the entire workforce:

Web-based, random access to all relevant information without hurdles

Mobile availability at all times:

Our MES software can be used on all mobile devices at any time

The latest cloud technologies:

For a scalable and flexible infrastructure and easier collaboration between different locations

Modern UI/UX design:

Flexible presentation of information without major training effort

Scalable container platform:

Low total cost of ownership through the use of our MES software

Integrated analytics tools:

These tools support data analysis, reporting, and trend detection.

Security and privacy technologies:

Protect sensitive lab information and comply with privacy regulations.

Interfaces and integration technologies:

Seamless integration with other systems in the lab.

Get in touch!

Would you like to know more about our MES software? Please write to us using the contact form. My colleagues and I look forward to exchanging ideas with you.

Dominik Weggler

Head of Sales at Germanedge