Lights-out planning: Autonomous planning in production

Autonomous planning for production

Autonomous planning is revolutionizing the management of supply chains and production processes. The intelligent combination of holistic modeling of the supply chain process, intelligent linking of all planning instances and a wide range of simulation and forecasting options creates systems that can make precise decisions without manual/human intervention.

This reduces complexity, minimizes costs and increases the ability to react to market changes – lights-out planning is therefore the perfect basis for fully networked and automated production.

Advantages of Lights-Out-Planning

Functions of Lights-Out-Planning

Automated scheduling

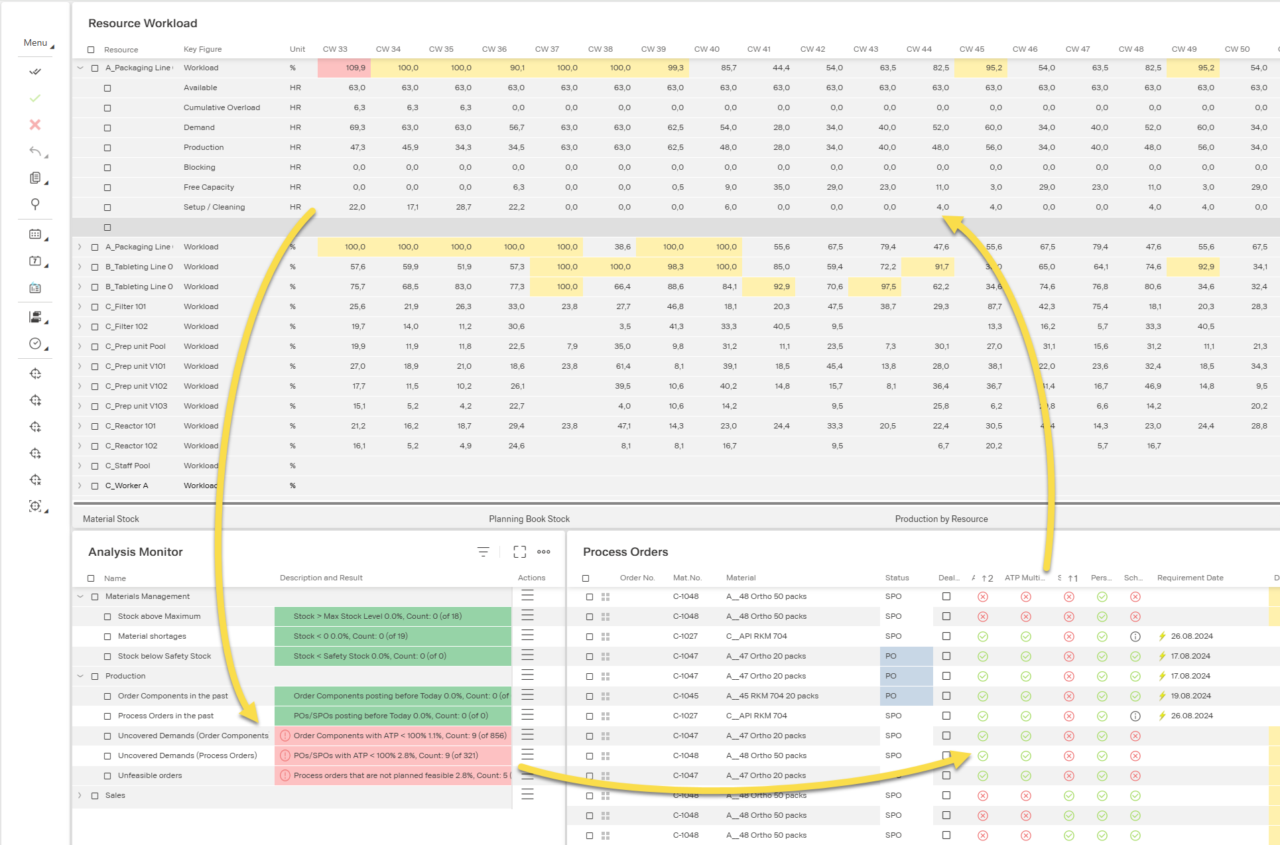

Automated planning is used to resolve planning conflicts immediately. This enables the system to react to short-term changes and resolve them. This allows production planning to be carried out in an energy-optimized manner and load peaks and energy consumption are reduced thanks to advanced planning algorithms.

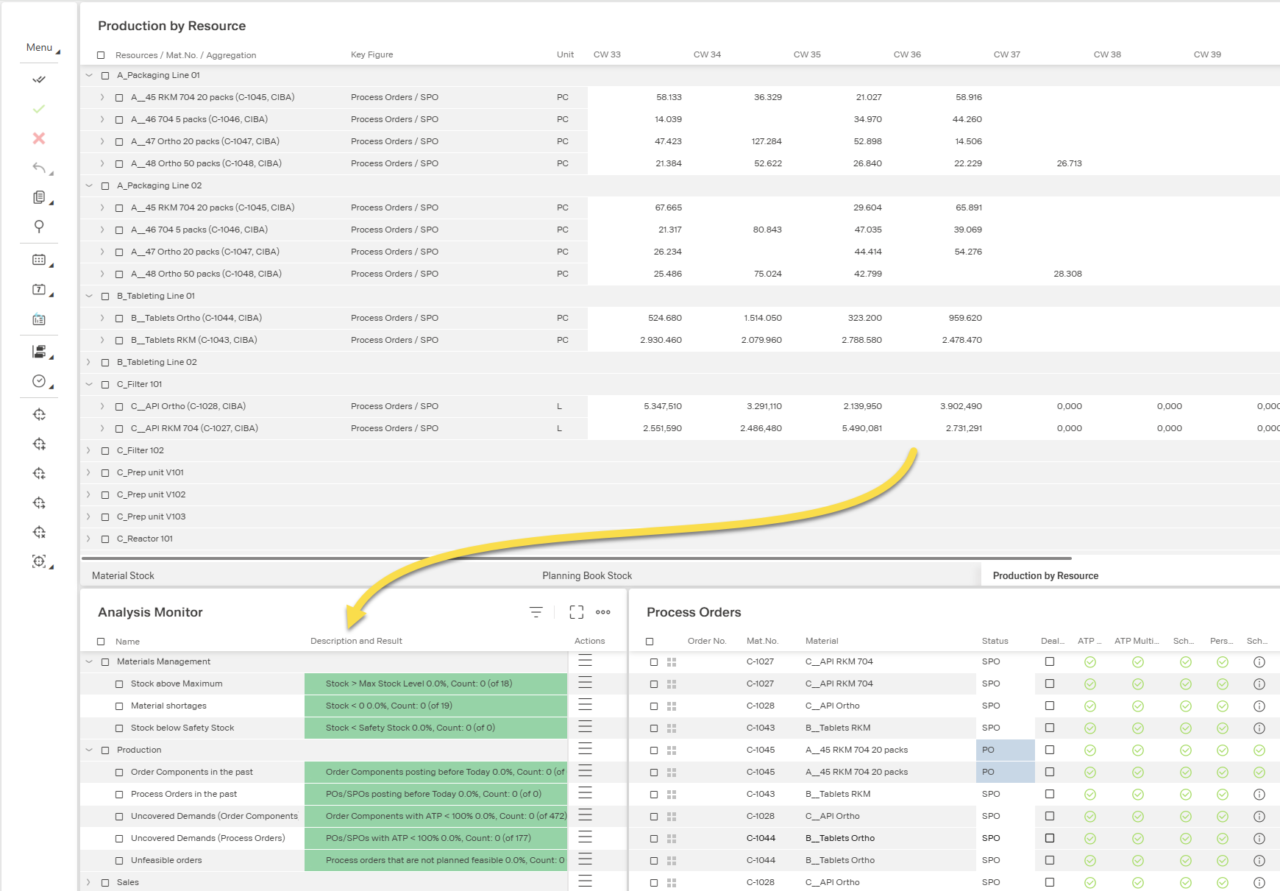

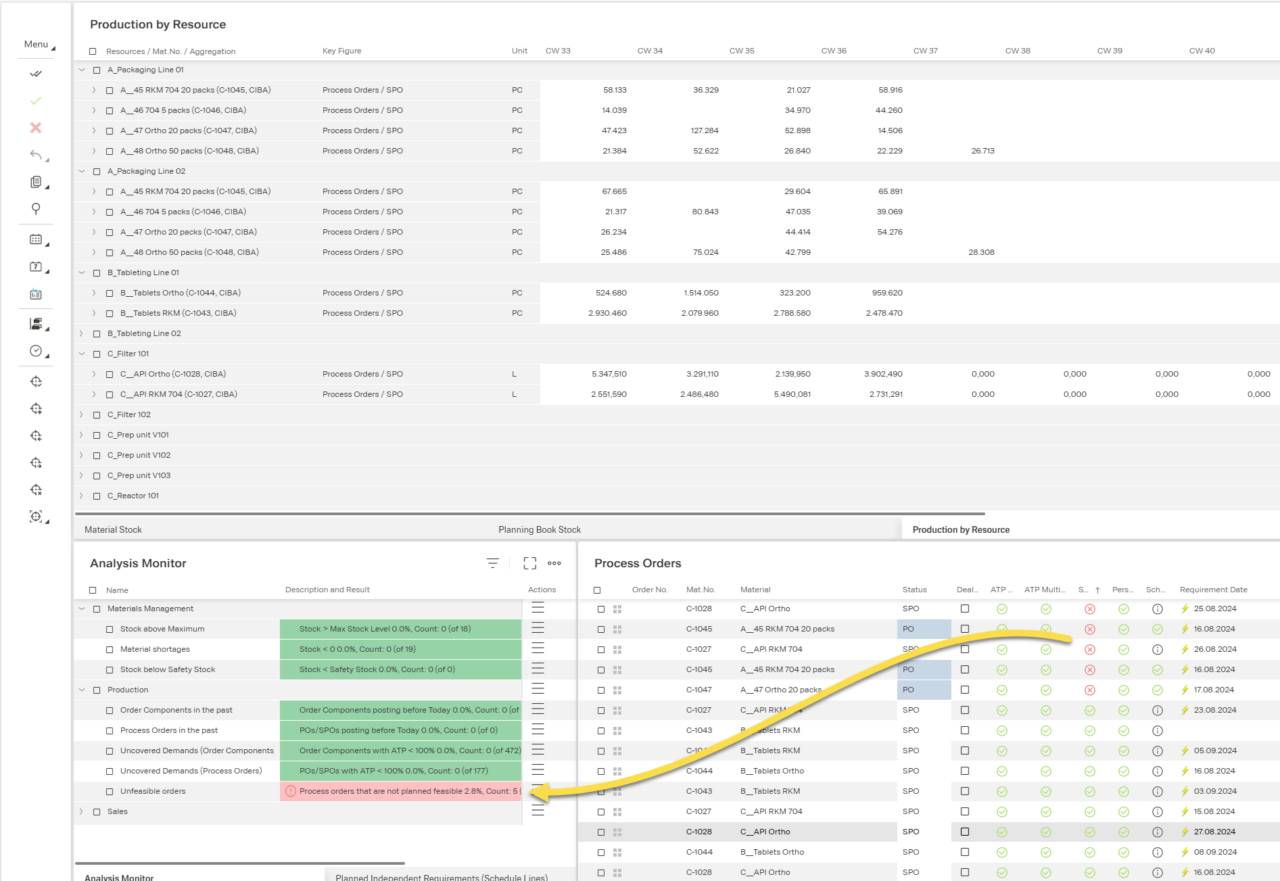

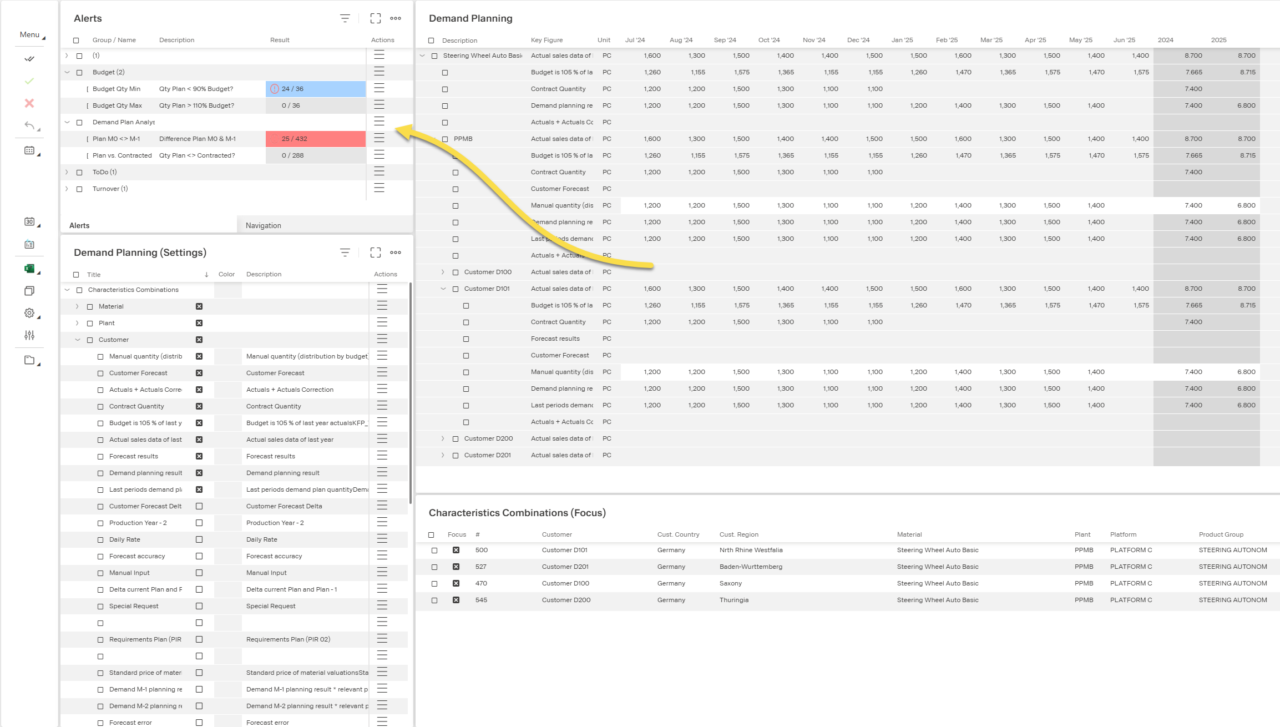

Use Case: Autonomization of Advanced Planning & Scheduling (APS) in the SAP environment

This use case describes the successful implementation of an autonomous planning environment for operational processes. The aim was to create a system that works completely autonomously in normal operation (happy flow), but automatically involves planners when certain events occur.

automatically.

Main features of the system:

Automation: the system takes over planning runs without manual intervention and reacts automatically to configurable events.

SAP integration: Bidirectional real-time interaction with SAP data (master and transaction data).

MRCP (Material Resource Capacity Planning): Use of complex planning logics that take finite resources into account and avoid overloads, which goes beyond standard SAP functions.

Capable to Promise (CTP): Automatic checking of the availability of resources and materials as a trigger for planning automation.

Target conflicts and alerts: Automatic detection of bottlenecks at material or capacity level with subsequent alerting, e.g. by e-mail.

Advantages and results:

Increased efficiency: automation reduces planning time and increases the quality of planning in your business.

Flexibility: The system can be individually configured, e.g. for material availability, personnel deployment or production restrictions.

Transparency: Real-time synchronization ensures that plans are always up-to-date and conflict-free.

This approach shows how autonomous planning instances can optimize processes and at the same time involve people as supervising actors.

FAQ: Frequently asked questions

What is Lights-Out-Planning and what are its advantages?

Lights-Out-Planning describes the ability of production and supply chain systems to operate autonomously and without human intervention. This is made possible by the combination of modern technologies such as digital twins, the linking of all planning instances and simulation and forecasting options. These systems make decisions autonomously and adapt dynamically to changing conditions.

What role do people play in autonomous planning?

People remain key players by defining the framework conditions, setting goals and providing monitoring support for the systems. In critical or unexpected scenarios, planners can intervene at any time. This transforms people from executors into strategic decision-makers.

Get in touch!

Would you like to know more about our solutions? Then please write us using the contact form. My colleagues and I look forward to exchanging ideas with you.

Dominik Weggler

Head of Sales Germanedge