Software for laboratory planning

Increasing efficiency and production through lab scheduling software

Laboratories are an integral part of industries such as life sciences, food and chemicals. Their quality control is of paramount importance, but can also become a blocking point in the supply chain.

In the laboratory environment, one hundred percent accuracy and blind trust are required in interaction. Laboratory planning plays a special role in terms of quality management and efficiency optimization.

Germanedge’s laboratory planning software gives you an efficient overview of the complex processes involved in laboratory planning, providing you with a transparent and realistic overview of future workloads and enabling you to increase the performance of your production.

Advantages of our LabScheduling software

Find out more at first hand

Would you like to find out more about laboratory Scheduling based on a use case?

Our case study from “Vetter Pharma-Fertigung GmbH & Co. KG” offers you in-depth strategic insights into a practical solution that is revolutionizing laboratories worldwide. Be inspired and discover how you can take your laboratory to the next level.

Functions of our laboratory planning software

Real-time synchronization of the plans

You can reload new or changed data from SAP, for example an inspection lot or a triggering object for an inspection lot, and thus have a comprehensive overview of the plans. Changes made can also be written directly back to SAP and are then immediately available.

Long, medium and short-term planning of laboratory capacities

A laboratory can quickly become overloaded, which then affects efficiency. To reduce this, individual or several inspection lots can be easily rescheduled at the same time. It is also possible to create simulative inspection lots so that you can recognize capacity bottlenecks at an early stage and rectify them.

Integration into horizontal and vertical planning levels without system breaks

The central data management of the LabScheduling software makes it possible to integrate capacities, material flows or personnel requirements for laboratory planning into all relevant production planning runs.

Planning horizon of laboratory planning analogous to that of production planning

This approach enables precise capacity forecasting and the early identification of capacity bottlenecks in the laboratories. Based on real-time data processing, it is possible to react flexibly to changing business events and carry out agile short-term planning of the laboratories.

Simultaneous laboratory and production planning

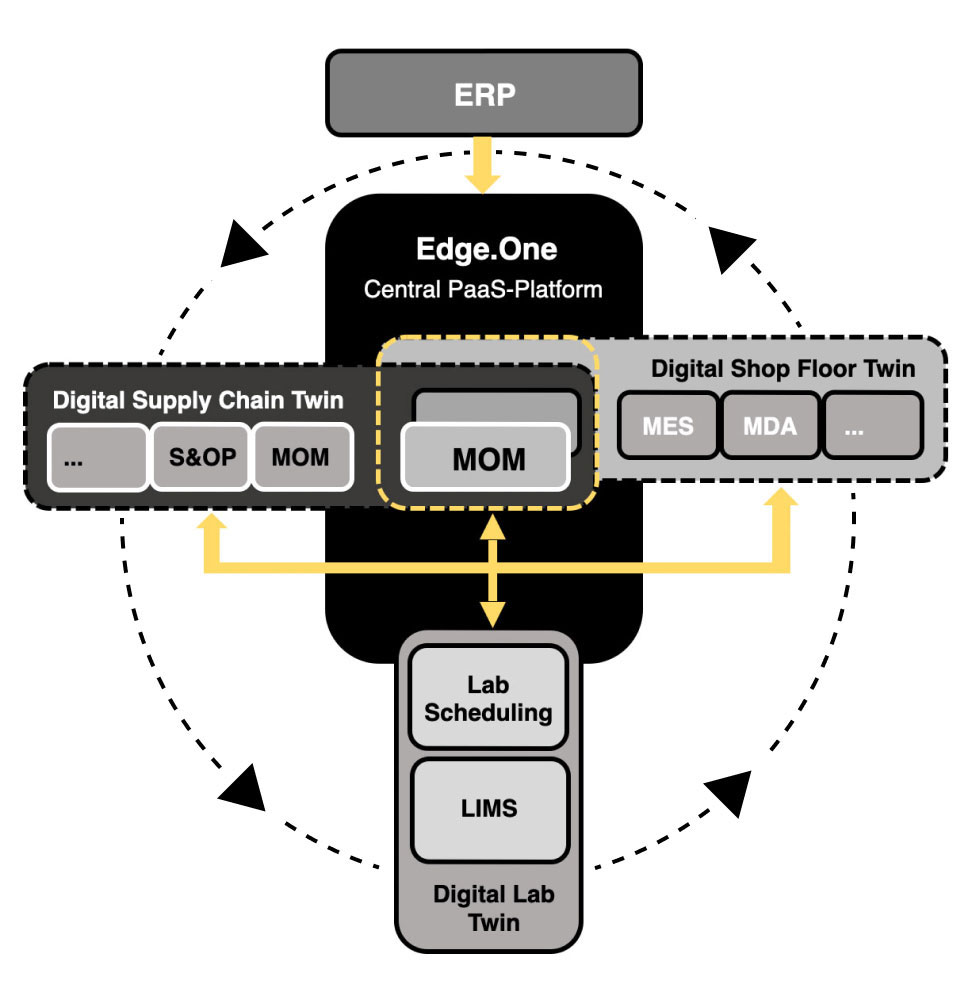

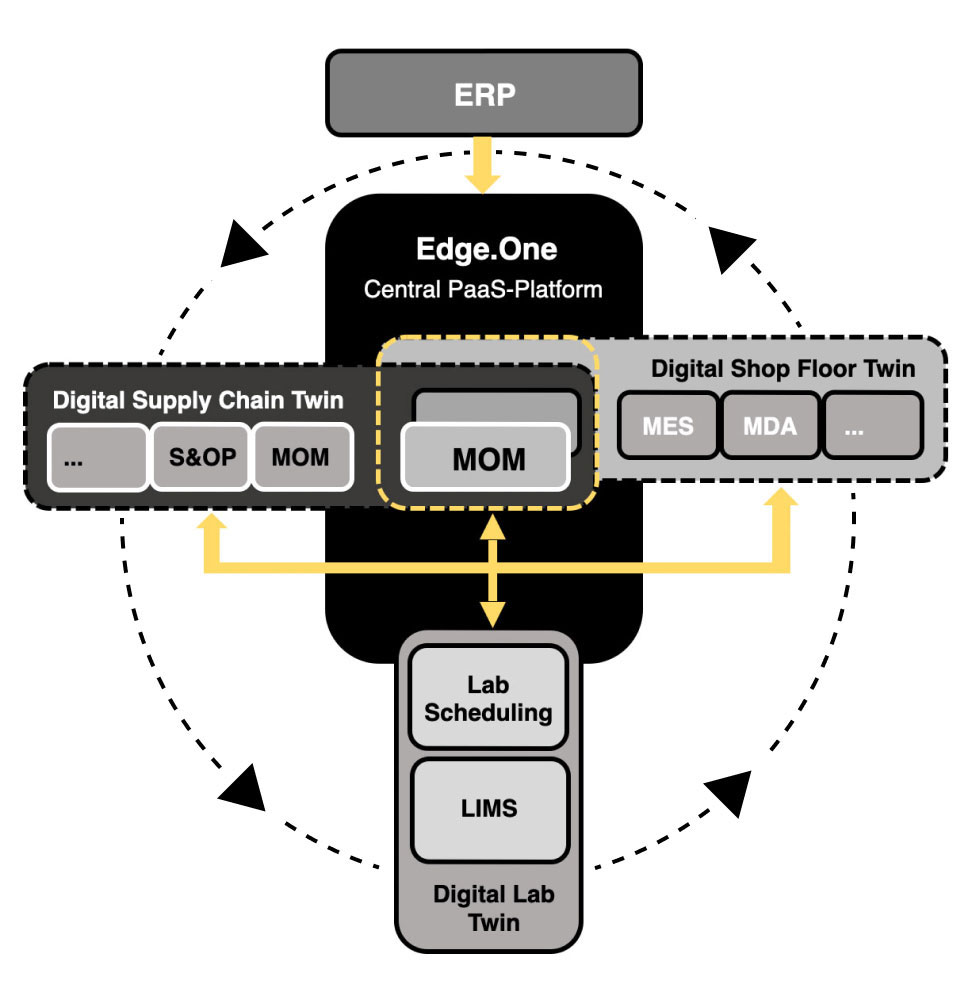

By using the Germanedge LabScheduling software, you can integrate laboratory planning into your company’s production and quality testing process. The lab scheduling software obtains all relevant (real-time) data via an interface connection to the ERP system (certified interface to SAP) and any LIMS and stores it in a shared database.

Thanks to the standardized data situation, the process integration and scheduling alignment of laboratory planning with production planning can be achieved with appropriate maintenance. The planning of inspection lots as a bottleneck criterion in the production process therefore has the same planning horizon as production planning and is enriched with the LIMS evaluations.

Integration of the LabScheduling software

Step-by-step instructions for integrating the LabScheduling software into your system:

- Contact us

- We show you the solution in a live demo

- We discuss the requirements and technical integration with you

- We support you with the integration and onboarding

Book your demo appointment now.

The laboratory planning software can be integrated in the following ways:

Certified SAP interface for SAP ERP and S/4HANA

Reading and writing of SAP QM objects: inspection plans, inspection lots, samples, notifications

External data sources can be connected via web service, e.g. external LIMS

What is a LabScheduling Software?

Definition

LabScheduling software is a specialized program designed to manage and optimize the use of laboratory resources. This includes the planning and allocation of laboratory workstations, equipment, materials and personnel. The software helps to manage lab resources efficiently by simplifying the booking and management of lab time, equipment and workstations.

Why is laboratory planning software relevant for your company?

LabScheduling software is relevant for companies that operate laboratories for several reasons:

- Increased efficiency: optimizing the use of lab resources can increase productivity and reduce the time spent on planning and organization.

- Cost reduction: Better management of equipment and materials can help reduce costs by avoiding unnecessary purchases and double bookings.

- Improved collaboration: The software enables better coordination and communication between employees, which is particularly important in research and development.

- Compliance and documentation: Many LabScheduling softwares offer features for regulatory compliance and documentation of lab resource utilization, which is important for audits and certifications.

What are the main components of LabScheduling software?

The main components of laboratory scheduling software include:

- Calendar and booking system: a centralized calendar that enables the booking and scheduling of lab time, equipment and workstations.

- Resource management: Management and allocation of laboratory equipment, materials and personnel.

- User management: Management of user roles and rights to ensure that only authorized individuals have access to specific resources.

- Reporting and analysis tools: Functions for creating reports and analyzing the use of laboratory resources.

- Integration: Interfaces to other software systems such as LIMS (Laboratory Information and Management Systems), ERP systems and other enterprise applications.

What are the advantages of launching LabScheduling software?

The launch of LabScheduling software offers numerous advantages:

- Optimized resource utilization: better planning and allocation of lab resources leads to more efficient use and reduces downtime.

- Time savings: Automated scheduling and management saves time that would otherwise be spent on manual tasks.

- Cost efficiency: Costs can be reduced by avoiding double bookings and optimizing the use of resources.

- Improved collaboration: Facilitates coordination and collaboration between different teams and departments.

- Transparency and traceability: Improved traceability and documentation of the use of laboratory resources.

- Increased flexibility: Quick adaptation to changes in planning and resource availability.

What functions does LabScheduling software have?

LabScheduling software can offer a variety of functions, including

- Booking system: allows you to reserve lab workstations, equipment and materials.

- Notification system: Automatic notifications and reminders for upcoming bookings or changes.

- Calendar view: Clear display of bookings and availability in calendar form.

- Resource management: Management and allocation of laboratory equipment, materials and personnel.

- Access rights: Management of user roles and rights to ensure that only authorized persons can book certain resources.

- Reporting and analysis: Creation of reports and analyses on the use of laboratory resources.

- Integration: Interfaces to other software systems such as LIMS, ERP systems and calendar applications.

- Conflict management: Detection and resolution of booking conflicts and overlaps.

These functions help to make the use of laboratory resources more efficient and transparent, which ultimately helps to increase productivity and reduce costs.

Get in touch!

Would you like to know more about our solutions? Then please write us using the contact form. My colleagues and I look forward to exchanging ideas with you.

Dominik Weggler

Head of Sales Germanedge