IT/OT Integration

IT/OI Integration

“Machine Data eXchange (MDX)” is a product family that is used in the context of industrial production to implement data exchange between machine controls (Operational Technology / OT Devices) on the shopfloor and various IT systems (Information Technology).

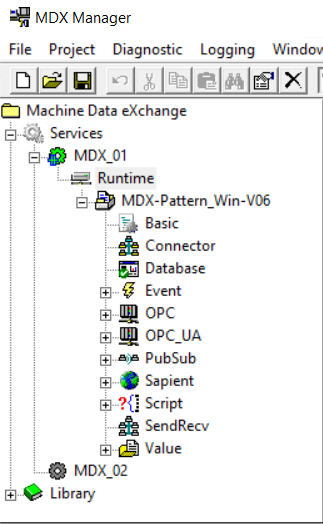

For this purpose, MDX offers several OT Connectors (OTC) for connecting OT devices and an IT Connector (ITC) for connecting to IT systems on Windows operating systems and various Linux distributions.

Project-specific scripting on-the-edge via IT/OT integration

Project-specific scripts can also be executed within the IT Connector. This enables the pre-processing and enrichment of data with its context as well as the implementation of customer-specific business logic. In particular, scripts can also be used to dynamically create and terminate connections.

This means that new machines and devices can be connected without having to restart the connectors. The MDX product family provides user programs under Windows for project planning. These programs enable easy deployment of the connectors, their parameterization and the creation of scripts for execution in the ITC.

Advantages of IT/OT integration

- IT/OT integration offers a wide range of options for (pre-)processing data

- The scripts within the Machine Data eXchange (MDX) are a flexible tool for program control

- An independent scripting language whose command set is adapted to the special requirements

- The syntax is based on a standardized language (Structured Text from IEC1131)

- Around 200 script commands are available for script programming and the scripts are processed in a strictly event-driven manner

- For complex applications, the scripts can be structured in a clear form (“building block box”)

- Frequently used scripts in the context of Legato Sapient (TPM) and EdgeOne are supplied in a library

MDX interfaces

There are many standard device integrations that are supplied out of the box – whether for the connection of different control types or for the integration of ERP, QM software or MES software.

The data connection can be made via different protocols such as TCP/IP, RFC1006, Modbus-TCP. The gateway offers OPC-Classic (OPC-DA), OPC-UA, MQQT and others as standard interfaces. In addition, the send-receive interface is used for telegram-based data connection.

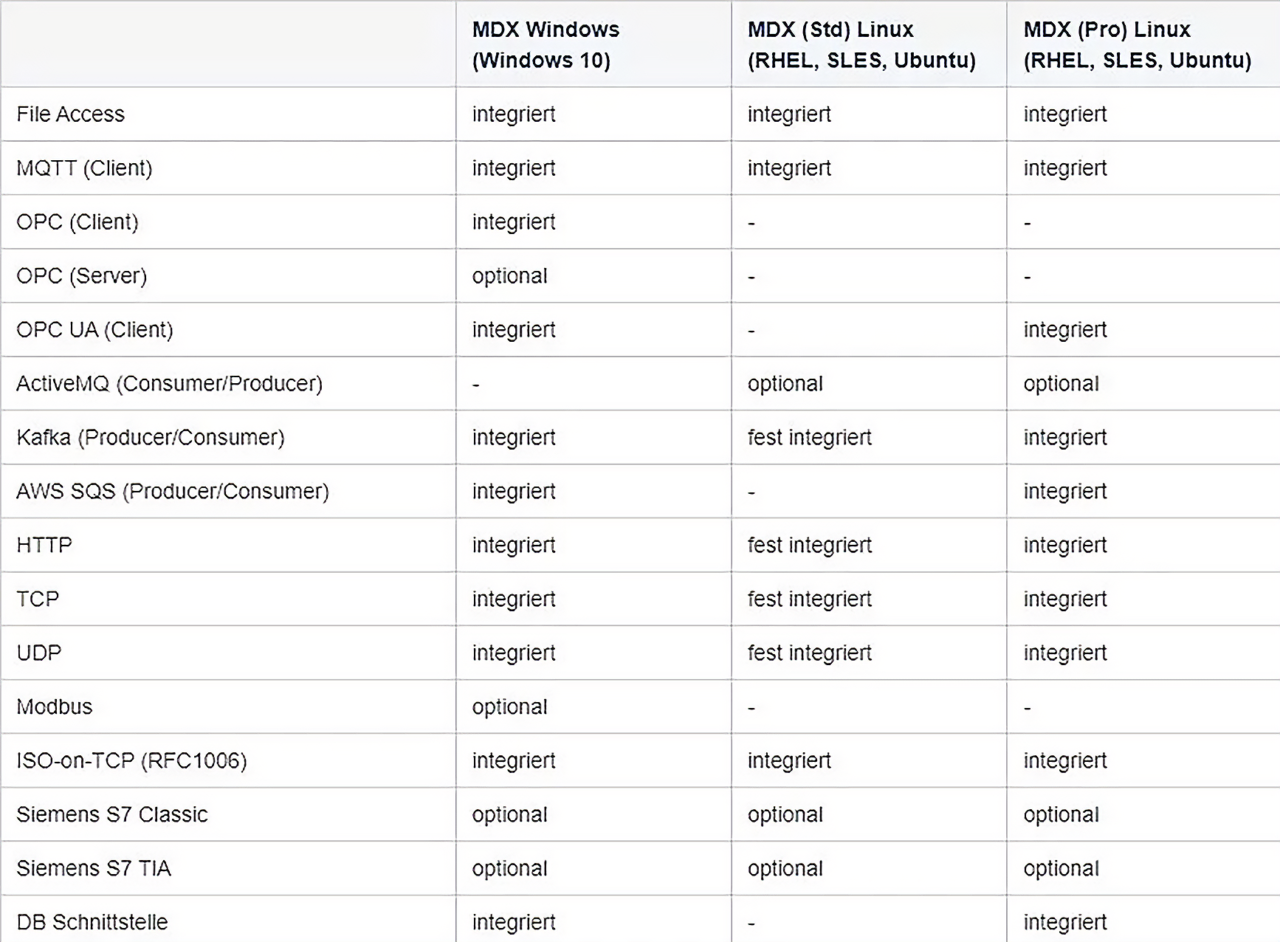

Due to the division of the product into IT Connector and (several) different OT Connectors, any number of device integrations can also be realized, including with the help of 3rd party driver modules. The following table provides an overview of the available device integrations within the MDX product family.

Machine and production data acquisition

Any type of data in a wide variety of formats can be recorded and processed by the MDX data gateway when connecting production systems or process devices. The type of data to be recorded is of secondary importance, i.e. it does not matter whether it is production data, order data, tool and fixture data or machine statuses, for example.

Furthermore, manual data entry (values, manual messages, message evaluation, etc.) can be carried out via the standard interfaces of the web client.

Application example: Commercial vehicle production - Central plant monitoring

- Real-time transparency of the entire factory across all trades

- Detailed drill-down analyses from factory, to area, line, station

- User-specific production dashboards, views for the respective user group (maintenance staff, shift supervisors, production managers, plant managers)

- Support for production, maintenance and plant management

- “Smart Maintance” with over 100 connected Smartwatches

- Result: Increase in OEE by increasing the number of units, techn.

availability and quality

FAQ: IT-OT Integration

What is operational technology?

Operational Technology (OT) is used in industry and comprises the control and monitoring of physical devices. OT is industry-specific and is often controlled in a self-contained system, such as a SCADA system.

The aim is to visualize and monitor production plants and all plant and process parameters with the additional option of controlling functions from the MES control station via setpoints and switching commands. One of the core tasks is to provide transparency about the production processes in order to register problems at an early stage, avoid breakdowns and thus ensure high plant availability.

What's the difference between IT and OT?

Information technology (IT) is defined as the data processing of administration, communication and organization. It serves the business overview and strategy. Operational Technology (OT), on the other hand, describes the combination of hardware and software that is used for the actual control and monitoring of machines. This involves the collection of physical data and the operation of devices. In the past, IT and OT were separate areas. Due to the connection to the Internet, an IT/OT convergence can be observed. Appropriate IT/OT integration is the key to success.

What are the advantages and disadvantages of IT/OT convergence?

The amount of data collected in OT opens up new options for action at a strategic level. Appropriate IT/OT integration allows the data to be interpreted at IT level and transferred to optimized processes. The challenge here is data security, which can become a new weak point for a company. The solution is therefore decentralized processing in which sensitive data does not leave the production site, so-called edge computing.

What is IT/OT convergence?

IT/OT convergence refers to the merging of the traditionally separate areas of information technology (IT), which is typically responsible for data processing and enterprise applications, and operational technology (OT), which is used to control and monitor physical processes and assets. This trend enables companies to increase efficiency, reduce costs and create new opportunities for innovation.

For which companies is IT/OT convergence particularly important?

IT/OT convergence is especially important for companies in industries such as manufacturing, energy, transportation, healthcare and others where the integration of data processing technology with physical systems and equipment must occur to optimize operations and gain competitive advantage.

What are the challenges of IT/OT convergence?

Some challenges of IT/OT convergence include security concerns (as OT systems have historically been less protected than IT systems), interoperability issues between different devices and systems, complex integration of legacy systems, and the need to combine expertise in both areas.

How can companies overcome challenges and exploit opportunities with IT/OT convergence?

Companies can overcome challenges by investing in robust security solutions, training their staff to enable IT and OT teams to work better together and through strategic partnerships with experts in the integration of IT and OT. Opportunities arise from improved data analysis, faster decision making, optimized operations and the creation of new business models.

What is the best way to proceed with IT/OT integration?

Successful IT/OT integration requires careful planning and step-by-step implementation. This can be done by developing a clear strategy, identifying priorities and key projects, selecting suitable technology partners and implementing solutions that ensure interoperability and security.

Why do you need good IT/OT integration?

Good IT/OT integration is crucial for companies to optimize their operations, reduce costs, drive innovation and increase competitiveness. It enables seamless data transfer and analysis between IT and OT systems, leading to better-informed decisions and more efficient business processes.

Get in touch!

Would you like to know more about our solutions? Then please write us using the contact form. My colleagues and I look forward to exchanging ideas with you.

Dominik Weggler

Head of Sales Germanedge