HMI Software - Your system for efficient production

Discover our HMI software: Your solution for efficient production

Our HMI (Human Machine Interface) software focuses on two key areas in production: the clear presentation of information and the simple operation of machines.

In view of the increasing complexity of modern machines, it is crucial to display a large amount of information in a small space. At the same time, this information must be displayed in an ergonomically sensible way so that the operator can quickly grasp and react to it.

This is possible with our HMI software. You can visualise the system in the browser and thus access all machine data flexibly. Thanks to our cloud-supported designer, you can easily configure and centrally manage visualisation screens.

Advantages of our HMI software

Functions of our HMI software

Decentralised perspective through HMI software

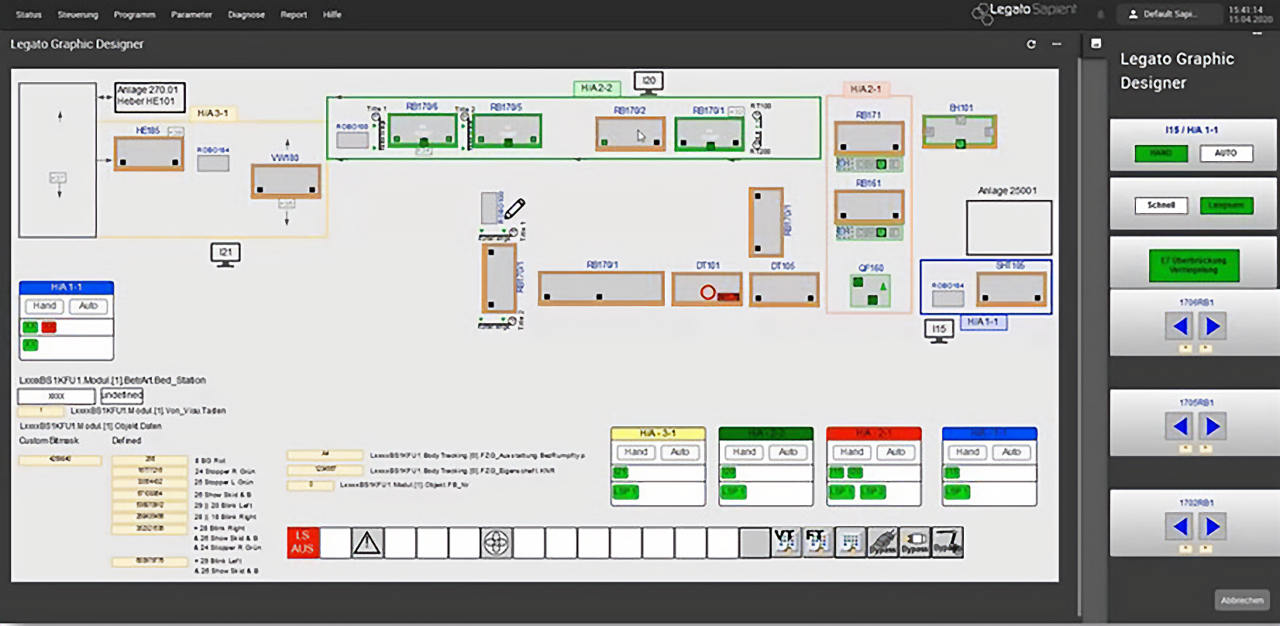

Our Germanedge HMI software is a server-based solution for graphical process visualisation and process-related operation. It supports up to one hundred individual stations with low latency (< 1 second) for production-critical interactions. The system has authorisation concepts for user-specific functions.

HMI Designer as a graphics editor for the visualisations

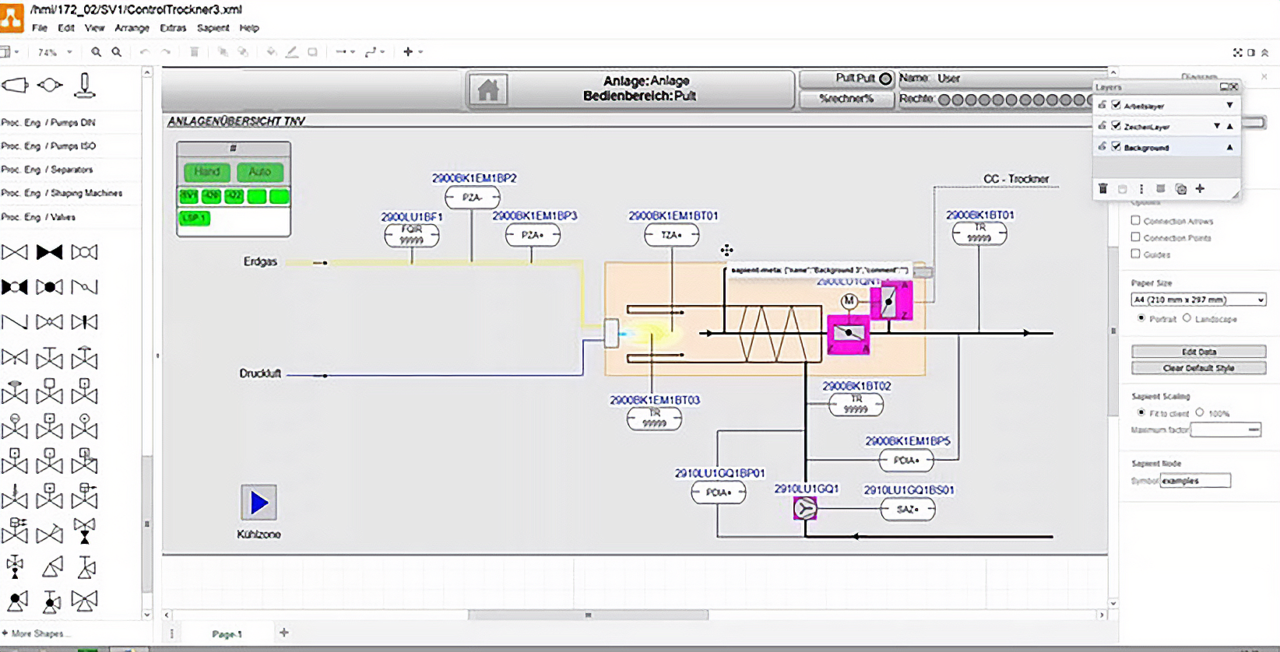

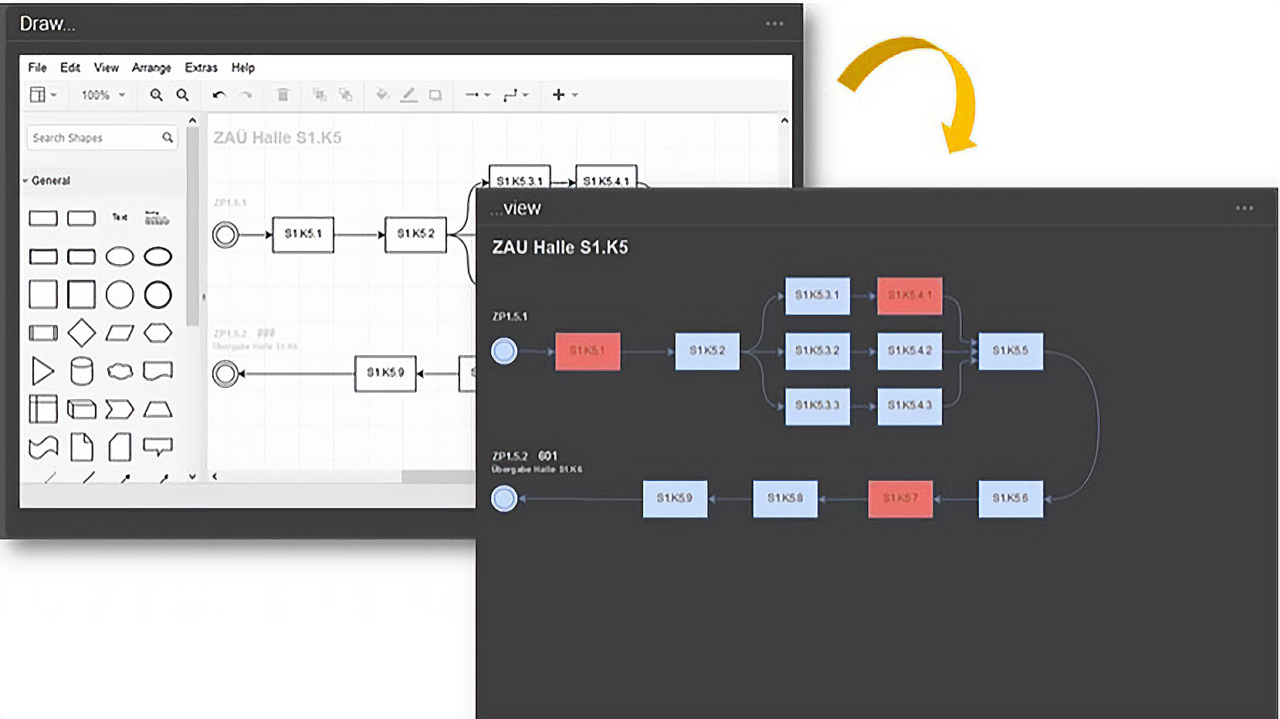

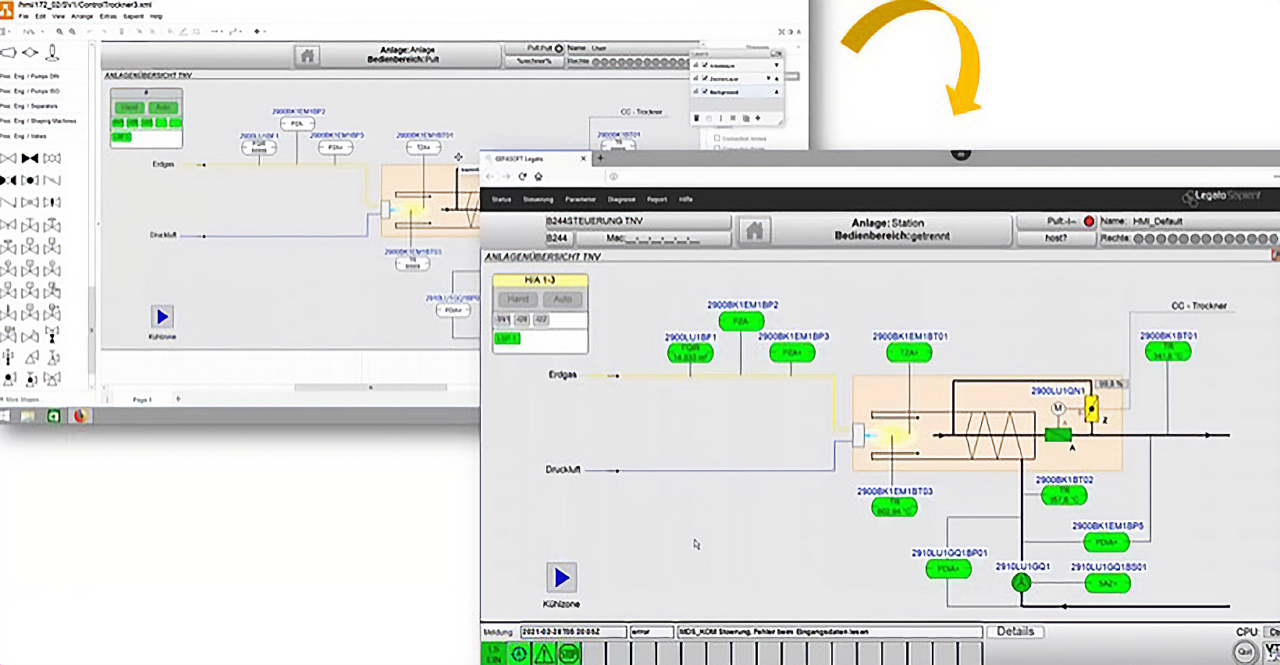

The designer of our HMI software is based on the platform-independent diagrams.net and is 100% web-based as a cloud solution. It is an integral part of Legato Sapient and offers standard libraries for graphical elements (e.g. process engineering according to ISO standards). Graphics can be loaded directly, edited and saved on the server.

Display of the visualisation in the web browser

With our HMI system, you can easily display visualisation data in the web browser and transfer it to the live view of the Legato Sapient MES system – with little effort.

Dynamisation of the HMI from the MES data pool

Data from the MES can be visualised in the same way as machine or process variables in the HMI. They are linked to visualisation elements via “data bindings” and can therefore dynamically change their style attributes. Dynamisation is achieved through simple calculations, logical operations or mapping functions. You can create project-specific visualisation objects including function logics and save these as templates in customer-specific libraries.

Integration of the HMI software

Step-by-step instructions for integrating the HMI software into your system:

- Contact us

- We show you the solution in a live demo

- We discuss the requirements and technical integration with you

- We support you with integration and onboarding

Book your demo appointment now.

All you need to integrate our HMI software is the HMI project and a mapping table. The system is installed locally and then connects to the cloud.

What is HMI?

Definition

HMI stands for human-machine interface and is software that can be executed directly via the terminal or next to the machine. It is used to control and monitor various real-time data and functions of the machine. The more user-friendly and customised an HMI is, the more efficiently the system can be operated by the worker and used for digital Shopfloor Management.

Where are HMI systems used?

In principle, HMI systems can be found throughout everyday life. All automated processes that are operated by humans, be it roller shutters, cruise control or robot vacuum cleaners, contain an HMI module. In automated industry, HMI softwares are used to control and operate machinery – so-called Industry 4.0. In addition to the manufacturing industry, HMI systems are also used in the wastewater, energy and food industries, among others.

What does the HMI have to do with SCADA?

An HMI module is a sub-component of a SCADA system. An HMI module is the direct control and operation of a machine. A SCADA system brings together all HMI modules and collects and stores the resulting data.

Why is HMI software relevant for your company?

HMI is the most important component for networking the digital factory at the individual workplace. It provides targeted machine and process information for the worker at the right time.

What factors influence the quality of the Human Machine Interface?

- instantaneous – I receive the information with virtually no delay.

- ergonomic – I can recognise the current status without any doubt. All relevant information is visible. Operating errors are practically impossible.

- Alerting – I am explicitly notified of important changes.

- Project planning – A simple and powerful designer enables me to create visualisations quickly and error-free with central management of all terminals.

Get in touch!

Would you like to know more about our HMI software? Then please write us using the contact form. My colleagues and I look forward to exchanging ideas with you.

Dominik Weggler

Head of Sales Germanedge