Shopfloor Management Software: Digital & productive

Shopfloor Management Software: From paper documents to the digital world of information

You are probably familiar with the “morning meeting” in the classic sense, in which all employees are brought up to date on the basis of overarching standards and topics from the previous day are discussed, right?

This is an effective way for companies to maintain an overview of all important information. Nevertheless, in the age of digitalization (digital factory), new opportunities and possibilities arise as to how existing processes can be adapted and optimized

The digitalization of the morning round as digital Shopfloor Management (dSFM) replaces the previous decentralized preparation of data in tools such as Excel or Power Point. Instead, a central store floor system is used to support the process of regular meetings. All relevant data is provided and additional information can be easily added to the digital store floor boards during the meeting.

Advantages of our Shopfloor Management software

Find out more at first hand

Would you like to find out more about Shopfloor Management using a use case?

Then read through our “Digital Shopfloor Management” use case and delve even deeper into the functions of the software using the practical example and a click demo.

Functions of our Shopfloor Management System

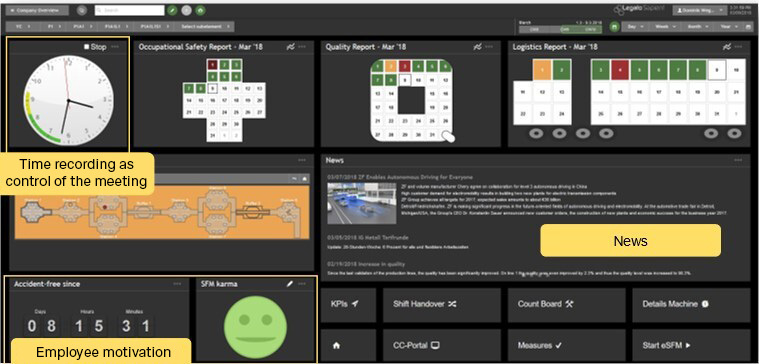

We would like to show you the various functions of the Shopfloor Management software based on the morning meeting process.

The following views in terms of presentation, layout and the morning meeting process are merely an example and can be flexibly adapted to the individual requirements for a store floor meeting.

Shopfloor Management overview

The start dashboard contains an overview of all important information on the store floor topics and serves as a direct entry point for the daily morning meeting. The course of the meeting is individually adapted to the core topics and needs of the customer for the respective store floor area.

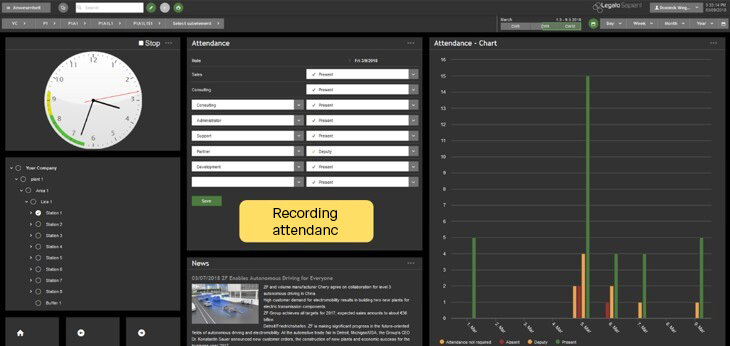

Attendance

Typically, the meeting begins by recording the presence of certain employees or groups of employees. This is recorded in minutes and can also be evaluated retrospectively in order to understand whether the necessary colleagues or their representatives were involved for certain topics in order to make the necessary decisions.

Subsequently, all individual topics are discussed together step by step, special incidents from the previous day are recorded and appropriate measures are taken. The clock as a time tracker serves as a reference point to ensure that the morning meeting is held “on time” within the predefined time.

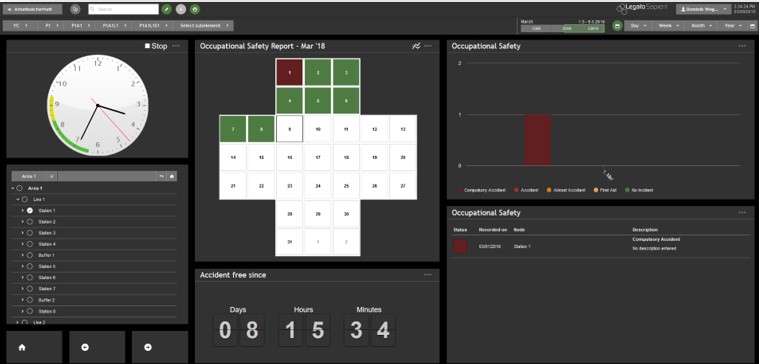

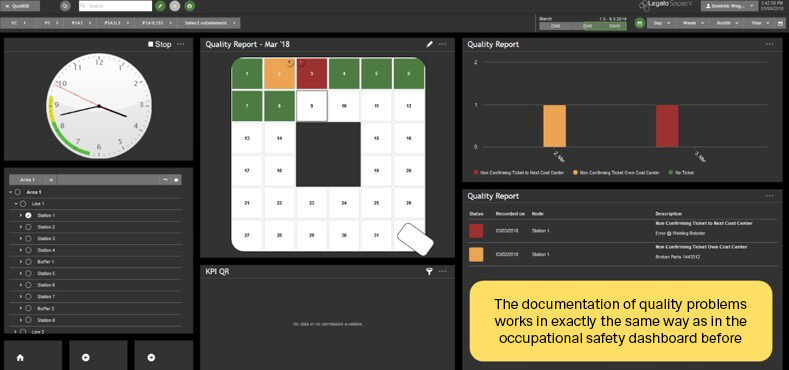

Occupational safety

Occupational safety is used to record occupational safety hazards. The so-called “work safety cross” shows the status for each calendar day of a month and indicates in color if certain events have occurred here. The details of events are also visualized graphically and in tabular form.

A dialog can be opened via the “Work safety cross” to record an event. It is also possible to create measures here, in which the exact tasks and other characteristics (responsibility, priority, to be completed by, etc.) are recorded.

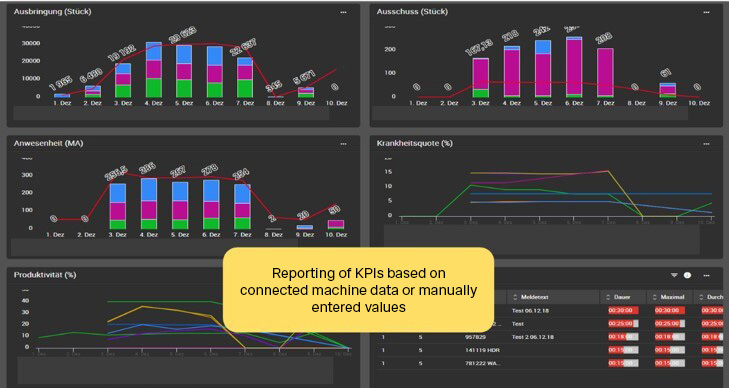

Reporting of production data and key figures

As a modular component of the Manufacturing Execution Systems (MES), dSFM can therefore use other existing MES views in order to integrate them into the morning meeting. This allows access to data that is automatically collected from the control systems in real time. This guarantees high data quality. Views such as key production figures or top faults provide an important basis in combination with other store floor topics.

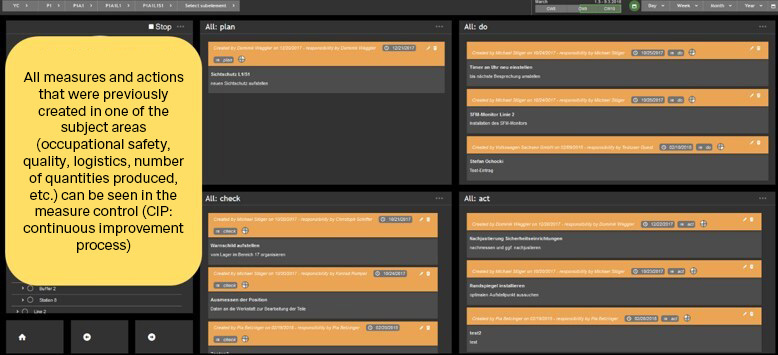

Measures management

The measures recorded during the meetings as the basis for the continuous improvement process (CIP) can be displayed in a separate view at the end of a meeting. Filtering for overdue tasks or responsibilities, for example, quickly provides information about the current situation and possible need for action. The details of each measure can be viewed and edited at any time.

Integration of Shopfloor Management software

Step-by-step guide to integrating Shopfloor Management software at your company:

- Contact us

- We show you the solution in a live demo

- We discuss the requirements and technical integration with you

- We support you with the integration and onboarding

Book your demo appointment now.

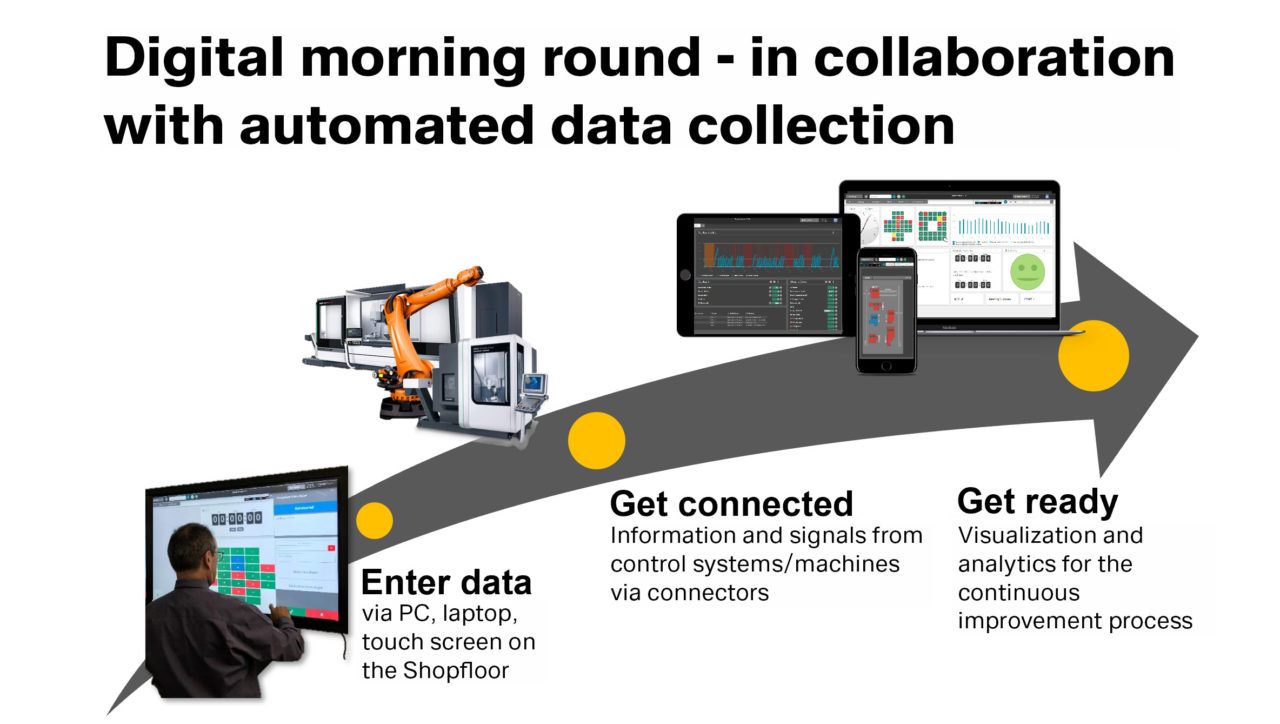

The integration of our Shopfloor Management tools is straightforward, as it can implement the processes of the morning round without the need for additional integration of other systems or controls. The information input is primarily provided by the employees. This means that a project can be implemented relatively quickly.

Of course, it makes sense to connect the machines in a further expansion stage, i.e. to record production and machine connections via controllers on the store floor. With this additional data in conjunction with dSFM, the benefits increase. The automatically recorded data with high data quality and in large quantities makes it easier to identify and evaluate incidents. This leads to the creation of better quality measures and thus to an improved CIP.

FAQ: How does Shopfloor Management work?

What is Shopfloor Management?

In manufacturing, “shopfloor” means something like “hall floor”, “workshop” or “factory floor”. It is the place where production takes place and added value is created. Shopfloor Management therefore means that management takes place directly on the shopfloor, i.e. the production and value creation processes are controlled by the active presence of managers on site.

Why is digital Shopfloor Management important?

On the one hand, digital Shopfloor Management is suitable for streamlining processes and minimizing production errors. You achieve noticeably more transparency on the basis of machine data acquisition and evaluation. Digital shopfloor systems enable relevant analyses in one place, in real time and with a low threshold.

What is a shopfloor meeting?

A Shopfloor Meeting is an effective production management tool. It usually has a regular agenda, takes place daily and lasts around 15 minutes. Shopfloor meetings are a dialog between production managers and employees and help to address process problems openly, get to the root of them and eliminate them quickly.

How can digital Shopfloor Management make production more efficient?

Digital Shopfloor Management can make production more efficient in several ways:

- Real-time monitoring and analysis: by digitally capturing data directly from the production floor, companies can obtain real-time information on the status of production. This enables a faster response to bottlenecks or problems.

- Optimization of processes: By analyzing the collected data, weak points in production processes can be identified and improved.

- Resource management: Better planning and utilization of machines, materials and manpower based on real-time data.

- Communication and collaboration: Improved communication between teams on the store floor and beyond, leading to smoother collaboration.

How can companies successfully implement digital Shopfloor Management?

The following steps are important for successful implementation:

- Set clear goals: Define what is to be achieved with digital Shopfloor Management (e.g. increased efficiency, error reduction, cost optimization).

- Choose the right technology: Selecting suitable software or platform that meets the company’s specific requirements.

- Training and introduction: Training employees in the use of the new technology and gradual launch to minimize resistance.

- Feedback and adaptation: Continuously collect feedback from users and adapt systems and processes accordingly.

- Ensuring data security: Implementing appropriate security measures to ensure the integrity and confidentiality of the data collected.

What are the advantages of Shopfloor Management for companies?

- Increased efficiency: Real-time data and better process control can improve production performance.

- Cost reduction: Optimizing the use of resources and reducing waste and errors leads to lower costs.

- Quality improvement: Better control over the production process leads to higher product quality.

- Transparency and traceability: Real-time data enables better traceability of products and processes.

- Improved communication: Better collaboration between teams on the store floor and with other departments.

What are the basics of Shopfloor Management in companies?

The basics of Shopfloor Management include:

- Visualization: Clear presentation of process data and information, often in the form of dashboards or digital display panels.

- Continuous improvement: Systematic analysis of production data to identify potential for improvement and implement measures.

- Teamwork and personal responsibility: Involving employees on the store floor in the improvement processes and promoting personal responsibility.

- Standardization: Definition of clear standards and processes to achieve consistent results.

Get in touch!

Would you like to know more about our solutions? Then please write us using the contact form. My colleagues and I look forward to exchanging ideas with you.

Dominik Weggler

Head of Sales Germanedge