More than just LIMS: Connected Lab-Management along the entire value chain

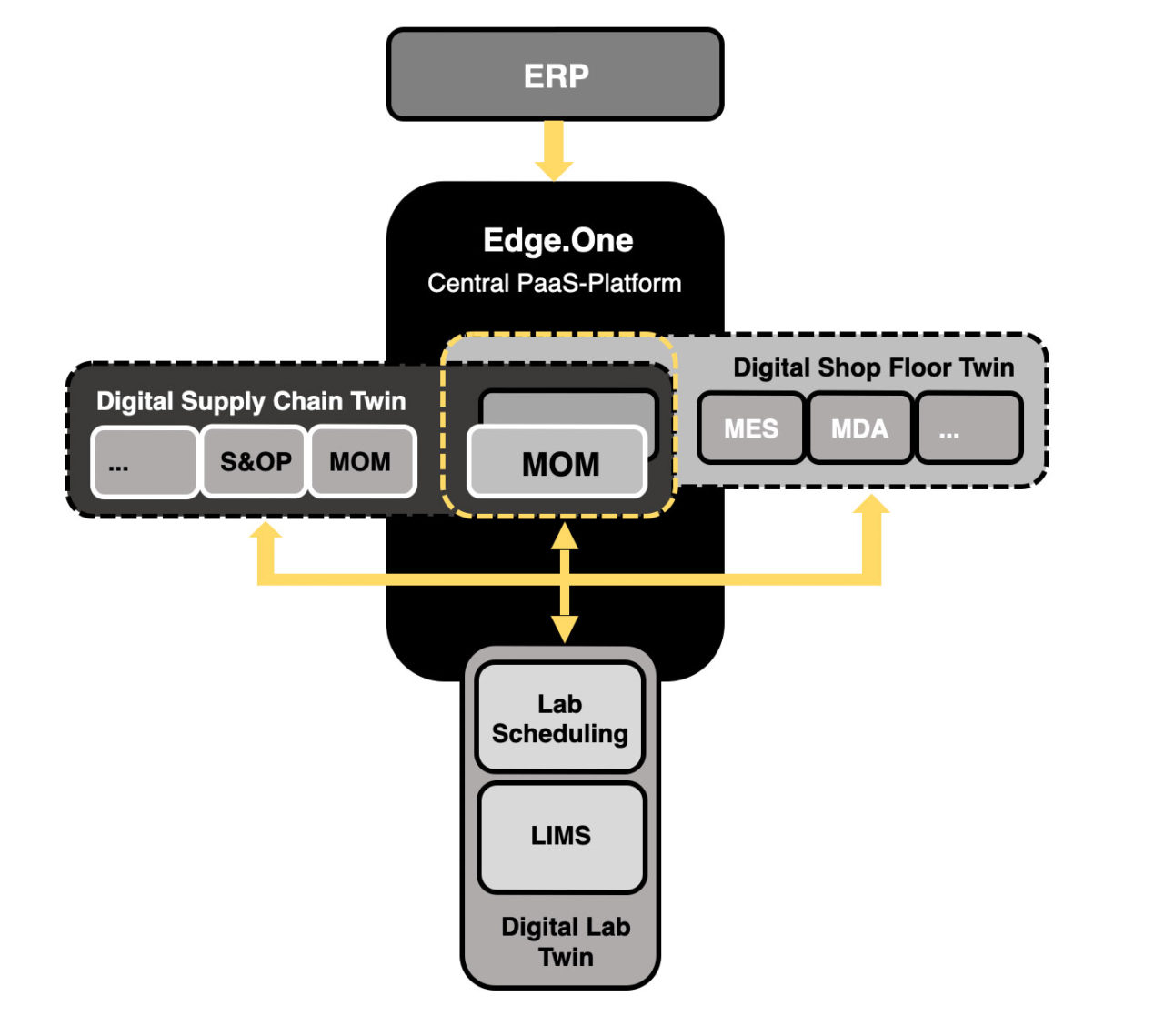

PaaS-Platform Edge.One enables labs to become an integrated part on planning and shopfloor level

With the global aim to increase efficiency, company’s digitization changeover strategy turns out to gain real momentum. However, these initiatives are often not well associated to counteract existing and still firmly cultivated “insular thinking”. Because a digitalised island is and remains just an island. The path to a digital factory can only succeed, if a holistic and networked approach is chosen. Of course, this also applies to laboratory management in particular, since laboratories are an area that is often neglected when it comes to “connectivity”.

As laboratories play a fundamental role in the process and manufacturing industry, they represent a time- and capacity-critical factor. What’s more, not all laboratories are the same: they differ fundamentally from each other in terms of their functional levels, e.g. development, QA and production laboratories. Unfortunately, labs are not always managed according to their central function and their interconnected tasks. Thus, they are often neither throughput optimised nor planned as a bottleneck of complex value chains or in line with the operational shop floor management. Hence, a very basic LIMS (Laboratory Information Management System) is often used as an isolated insular management tool that is neither horizontally nor vertically embedded in central corporate processes.

Digital Lab Twin enables a holistic and connected monitoring on limited lab capacities

What is actually a digital twin? Analogous to genetics – where identical twins share identical DNA – the Digital Twin shares specific functional characteristics with its analogue brother or sister. Looking at laboratory level, the digital twin combines LIMS and laboratory planning and integrates them into the central medium- and short-term planning process at execution level – and links the lab environment with the central ERP. Therefore, lab capacities should be considered similar to classic production resources and should go in line with their planning. This enables both long-term advanced lab capacity planning as well as tactical-operational capacity adjustments and scheduling.

Hence, the Digital Lab Twin provides answers not only to the central questions of “What?” and “How?” from the LIMS environment, but also to “When?”, “Where?” and “Who?” from the planning environment.

PaaS-Application Edge.One: The central hub for a synchronized real-time laboratory management

The central PaaS-application Edge.One enables an integrated laboratory management based on the analyses of data from the LIMS system as well as from Advanced Planning & Scheduling on ERP level. As a central element of the Digital Lab Twin, a LIMS is designed to facilitate the organization and workflow of laboratories. Its architecture utilizes a central database of samples that combines all results, instruments and metadata. This ensures that the workflow and data tracing in the laboratory remain efficient, secure and compliant with regulations.

The Digital Lab Twin thus combines the central LIMS with all planning levels – from production planning to the operative execution of lab planning – to guarantee a central data storage between the systems and the avoidance of system breaks. This includes capacity, resource and headcount planning to the lab management. As the planning horizon of laboratories is analogous to that of the production planning, it enables precise capacity forecasting and early identification of capacity bottlenecks in the laboratories. Within the operational planning cycle, real-time data processing allows for a flexible response to changing parameters and agile simulative detailed planning of the laboratories.

One step closer to the digital factory: The all-in-one digital Lab Twin

Get in touch!

Would you like to know more about our solutions? Then please write us using the contact form. My colleagues and I look forward to exchanging ideas with you.

Dominik Weggler

Head of Sales Germanedge