Advantages of Digital Factory Scheduling

Discover the possibilities of Digital Factory Scheduling

Multifaceted conflict management

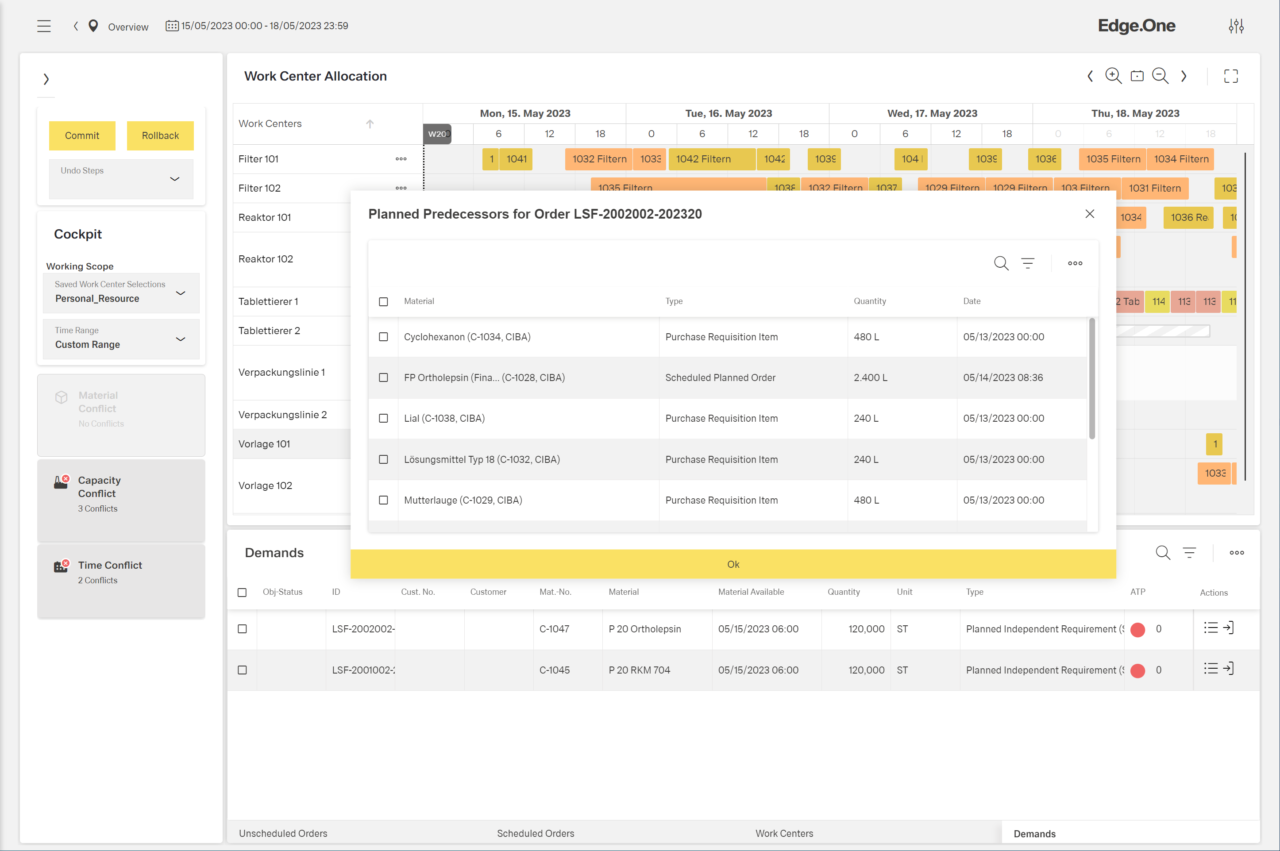

Smart conflict management with the help of alarms: Our system detects conflicts at an early stage and alerts you so that you can react quickly and find solutions. Likewise, we provide you with planning suggestions for conflict resolution: Our system provides you with suggestions for resolving conflicts to make your planning processes run more smoothly.

Keep the overview

Multi-level monitoring at sales order level: Keep track of your sales orders at different levels and make sure everything is running smoothly. Similarly, you can choose between manual and automatic scheduling for fast results, depending on your needs and goals, to get the best results quickly.

Now more efficiency in your production planning

- Rapid return on investment after 1-2 years

- 1-3% higher OTIF (On-time-in-full)

- 25-50% lower planning effort

- 5-15% shorter lead times

- 10-25% less safety stock

- 10-40% lower setup and changeover times

More apps to help you build your digital factory!

Digital shift book

With our digital shift book, you can create, edit and delete shift events.

Compared to the paper or Excel-based shift book, you can perform analyses and reports in the web applications to get a quick overview.

Document Management System

A standard-compliant DMS controls the lifecycle of all your documents. And this is 100% traceable! A DMS creates a revision and legally compliant information system for handling QM documents.

Frequently asked questions about Digital Factory Scheduling

Is there a period of notice?

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor.

What happens after the free trial phase?

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor.

Can I change my payment plan at any time?

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor.

How can I pay my subscription?

Wir akzeptieren Kreditkarten, SEPA Lastschriften oder eine Bezahlung über Paypal.

Choose payment options

Digital Factory Scheduling, your solution for efficient production planning tasks

- 2 planning users

- up to 5000 material masters

- up to 200 resources/workstations

- up to 2000 recipes/routing plans

- up to 5000 orders

- Alert monitor (notification) for material and resource planning

- Simulation capability and step-by-step rollback

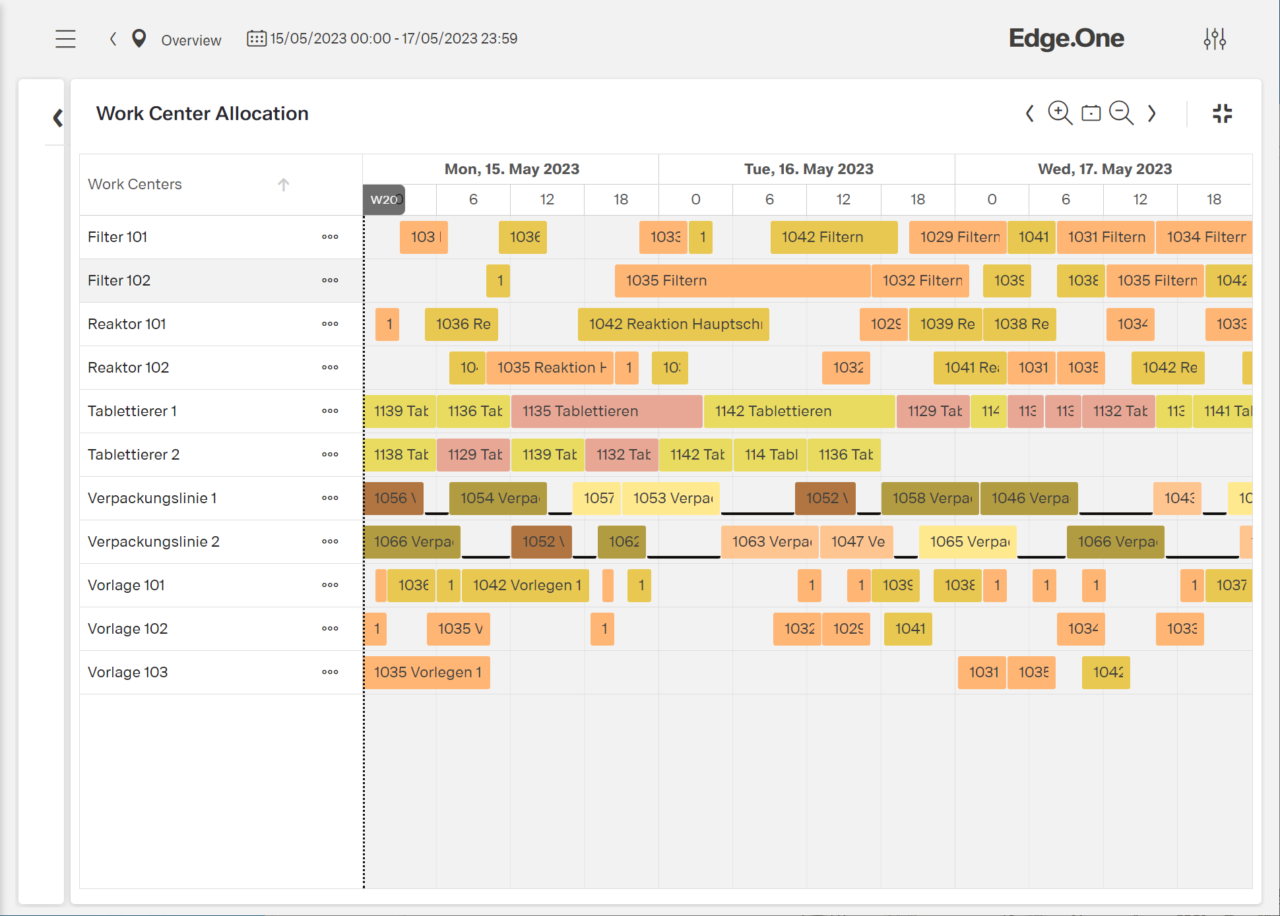

- Gantt chart functionality for visualization of the current production plan

- Planning suggestions based on algorithms

Digital Factory Scheduling, your solution for efficient production planning tasks.

- 5 planning users

- up to 10000 material masters

- up to 500 resources/workstations

- up to 3000 recipes/routing plans

- up to 10000 orders

- Alert monitor (notification) for material and resource planning

- Simulation capability and step-by-step rollback

- Gantt chart functionality for visualization of the current production plan

- Planning suggestions based on algorithms

Digital Factory Scheduling, your solution for efficient production planning tasks.

- unlimited users

- unlimited master materials

- unlimited resources/workstations

- unlimited recipes/routes

- unlimited orders

- All Professional Features included

- Planning suggestions based on algorithms

Get in touch!

Would you like to know more about our solutions? Then please write us using the contact form. My colleagues and I look forward to exchanging ideas with you.

Dominik Weggler

Head of Sales Germanedge