Supplier quality management ensures excellence and trust

No more complaints about product quality thanks to optimized supplier relations

Trust in the supply chain is a daily challenge, especially for complex, industrial products. Each and every component, resource, valuable substance and raw material must always meet the highest quality standards. In some cases, product parts or entire products are manufactured by suppliers or contractors. The company-wide quality standards must always be applied here.

A precise, transparent, and durable process network between your company and the suppliers or pre-producers (contract manufacturers) must be in place to ensure compliance with the required standards. But how resilient is this network, given the simultaneous increase in requirements due to state and regulatory regulations, ever smaller and more customer-specific products with changing components, and ever faster product cycles?

The answer to this question is: digital supplier quality management.

Supplier quality means partnership with suppliers

The establishment of and compliance with binding quality standards by suppliers and contract manufacturers in their own supply chain is the basis for market success. Unwanted and unforeseeable fluctuations can lead to expensive recalls, declining profitability, loss of customer confidence, and other costly consequences. A well-managed supply chain can be the competitive advantage that reduces your time-to-market and product manufacturing costs. Consequently, digital supplier quality management must

- optimize the fluctuations in the supply chain down to zero,

- establish a mutually beneficial partnership,

- offer existing as well as future products with the best possible features for the customers in the highest possible quality of your end products.

Compliance with your own, regulatory, and customer standards through digitalization

The days of paper-based or Excel-based exchange of quality protocols, certificates, test evaluations are over. An end-to-end quality management process that relies on the involvement of external suppliers or producers in order to implement customer requirements in the best possible way requires a digital and centralized overview of all quality-relevant data at a click. The consolidation of the data enables the development of new products, some of which were also produced by supplying companies. The digitalization of external manufacturing and the long underlying supply chain create uniform standards and transparency which lead to better compliance with the brand promise to the customer.

Expansion of the supply chain and simultaneous extension of customer benefits through controlling

The expansion of supply chains in relation to suppliers and pre-producers has additional challenges in the area of controlling & finance, especially in the case of contract manufacturing. Different invoicing dates for suppliers, sometimes before invoicing their own end customers, can stand in the way of commercial success. Digital supplier quality management provides a precise overview and an interface for internal controlling/finance, so that every supplier and pre-producer can be billed according to milestones reached. Likewise, a delay in delivery and other relevant parameters in the supply chain can be processed for controlling/finance.

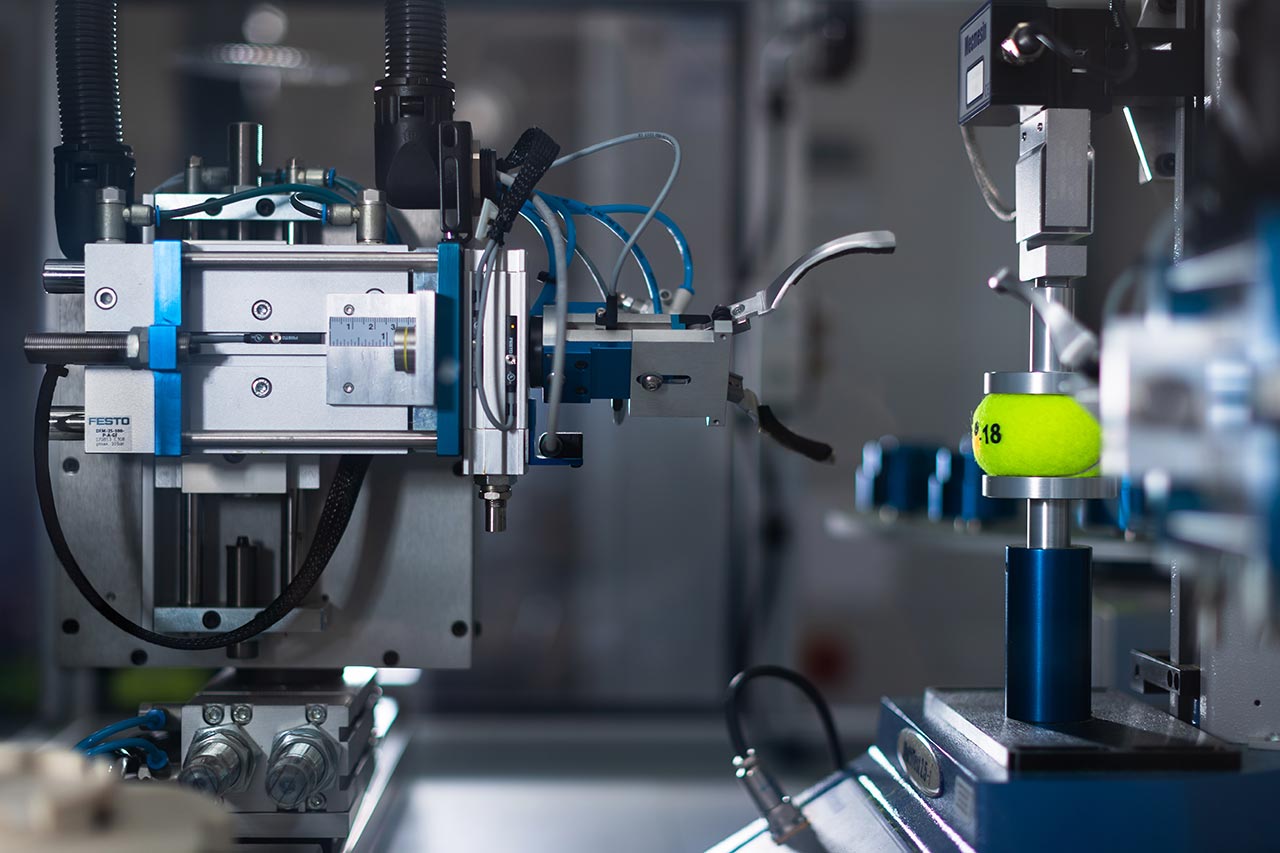

Batch-accurate tracking of individual components and resources thanks to traceability

Complicated end products, as are often created in industrial manufacturing, require a transparent and continuously traceable overview of the parts, raw materials, etc. used to make them. In the event of a change in regulatory requirements or production errors within the company or by suppliers, the impact on the end product must be clearly identifiable, as in individual cases only certain batches may be affected. With digital supplier quality management, the costs and efforts involved in recalls or service operations can be limited and minimized to very specific batches. Traceability of the individual components and materials together with the digital link to the production management of the end product guarantee seamless traceability.

Germanedge optimizes your supplier quality to ensure excellence

Those who promise high product quality should be able to keep their promise to customers. In complex production worlds it is therefore essential to ensure quality standards from A to Z. In the best case, external manufacturing transforms the suppliers involved into a value-added partnership supported by technology.

Only in a partnership with the appropriate digital solutions can problems be identified in good time and major damage to the products and the reputation of the manufacturing company be avoided.

At Germanedge, we believe in processes such as Design Thinking to constantly challenge and improve the status quo. We understand and support the search for excellence – not only in our customers’ production lines, but also in their supplier network and therefore also support supplier quality management.

Comprehensive control of external manufacturing with EdgeOne

EdgeOne combines enhanced traceability of all components of the end product through the entire supply chain with a digital checklist and supply chain management for transparency throughout the entire production process of all suppliers and pre-producers alike. Connected to the digital controlling, planning, and finance processes, the production-related accounting and planning process is also effective when many different suppliers are involved. With EdgeOne, the complicated becomes less complicated and the complex becomes manageable.

Get in touch!

Would you like to know more about our solutions? Then please write us using the contact form. My colleagues and I look forward to exchanging ideas with you.

Dominik Weggler

Head of Sales Germanedge