- SME Initiative

-

Digital Factory

The Future of Digital Factory

Our elements of the Digital Factory

- MES/MOM Platform PaaS: Edge.One

- + – Production Management

-

+

–

Quality Management

- CAQ Software

- Quality Management Software

- SPC Software

- Complaint Management Software

- Manufacturing Document Management Software

- APQP Software

- LIMS Software

- Supplier Relationship Management Software

- Measurement Data Management Software

- Traceability Software

- Joint Technology Software

- Calibration Management Software

- Audit management

- + – Connected Worker

- + – Planning

Elements of the Digital Factory

-

Solutions

Production Management

Quality Management

- CAQ Software

- Quality Management Software

- SPC Software

- Complaint Management Software

- Manufacturing Document Management Software

- APQP Software

- LIMS Software

- Laboratory management software

- Supplier Relationship Management Software

- Measurement Data Management Software

- Traceability Software

- Joint Technology Software

- Calibration Management Software

- Audit management

Connected Worker

-

Resources

Schlauer Raum

Company

Support

- Career

- GermanedgeNOW

- DE

From paperflow to digital dashboards: the new era of shopfloor management

How the use of a cloud-based PaaS infrastructure can turn decentralised information silos within the shop floor management into a smart factory approach!

Corporate digitalisation campaigns often underestimate the need to include the administration, control, and monitoring on shopfloor level. Thus, classic topics of the daily shop floor meeting – such as daily targets, target/actual comparisons, reject rates or safety issues – are still presented in the form of Excel evaluations and with whiteboard markers on pin boards. As the well-established format is nothing bad at all, critics is rather about its delayed, out-of-date or often inconsistent data quality caused by one-dimensional, decentralised and asynchronous information processing. The result: A competitive disadvantage that should not be underestimated in the dynamic daily shop floor routine.

Digitisation of the daily shop floor meeting = digital shop floor management?

Based on the PDCA cycle – Plan!, Do!, Check!, Act! – digital shop floor management (dSFM) has the task of creating transparency to centrally control processes and resources at production and workshop level. In this way, disruptions and deviations from the standard process can be detected. Tools on what initially caused them can thus be provided. By automating the provision of information, processes can also be accelerated considerably. With the objective of designing a continuous improvement process, the advantages of dSFM are apparent:

Central system for real-time data collection, its archiving and provision as well as its processing

Shift and interdepartmental information transfer

Creation of flexible analyses along any areas and time periods without further preparatory work

Easy third-party systems data integration (e.g. quality and logistics systems) into the central system

Reasons for plan deviations can be systematically analysed in a cascade and be resolved

Systematic analysis of the link between error, cause and effect

But let’s get back to the initial question. We are convinced that dSFM is more than the digitalisation of the daily shop floor meeting. It is rather an essential key on the way to the digital factory. But more on that in a moment.

Digital shop floor management 2.0: Creating holistic networking to set-up the digital factory of tomorrow

The digital factory grounds on the principle of the digital twin. Analogous to genetics – where identical twins share identical DNA – the digital twin shares specific functional characteristics with its analogue brother. In the smart factory, formerly isolated solutions and information silos in the shop floor (actual state) and supply chain management (planning state) are merged into a common digital ecosystem. So far so good! But aren’t several digital twins then again “just” an improved information silo? Slow down! The path to the digital factory is not taken in a sprint, but in smart steps! The ultimate goal is to synchronise digital twins into a digital hub in a holistic end-to-end approach.

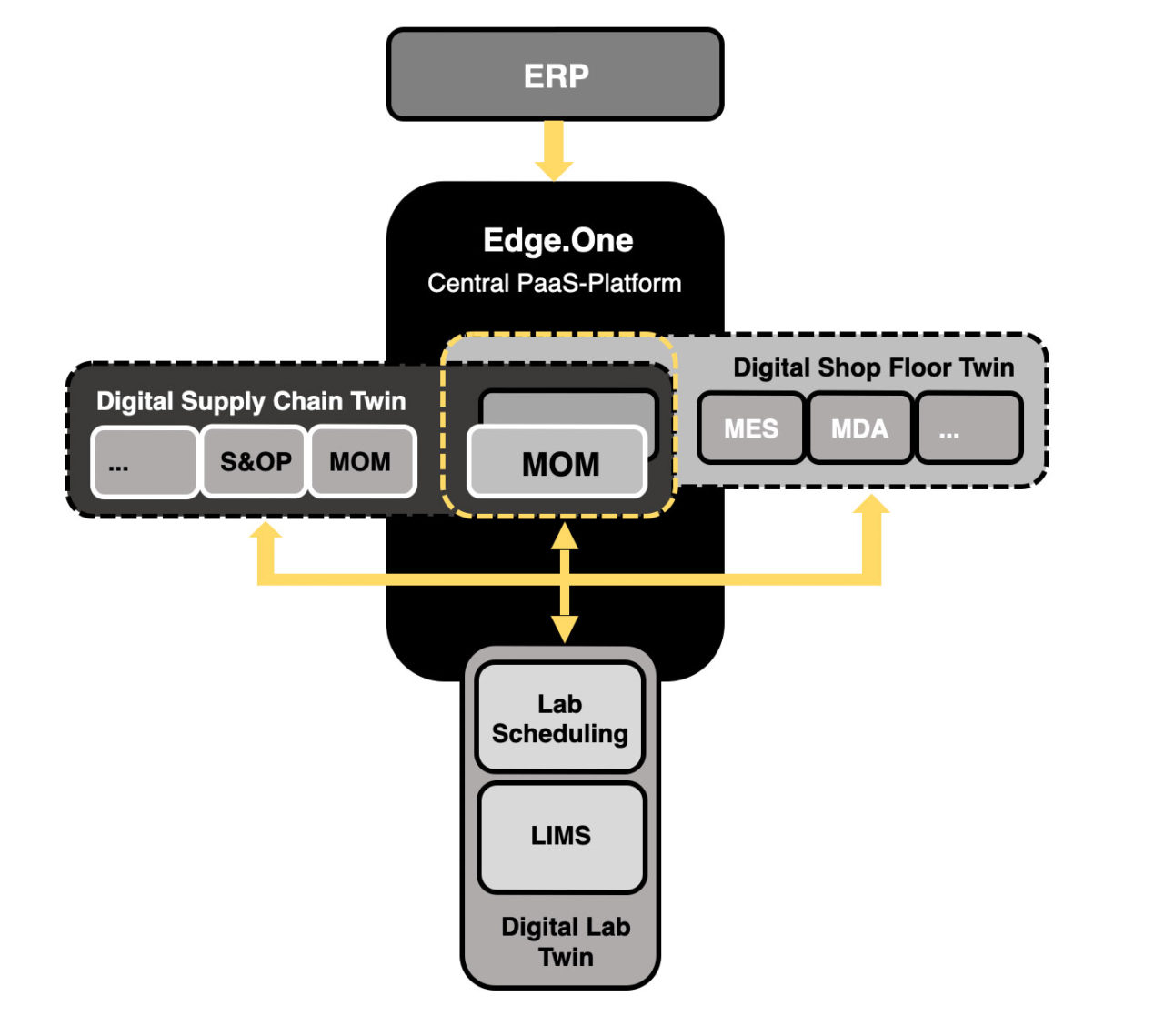

PaaS solution Edge.One: The central hub paves the way to cloud computing

The dSFM requires a clear architecture of the applied software. In addition to the classic structure – backend, applications and frontend – a PaaS solution paves the way to the networked future factory.

Backend Architecture

Information from machine, product, process and quality data collection, from material movements, etc.

Applications

Manufacturing Execution System Advanced Planning & Scheduling (APS), incident & action management, staff scheduling, and others

Frontend Architecture

Display of real-time KPIs

Due to its open interface infrastructure, Edge.One enables the linking of modular web applications from shop floor management, supply chain management, laboratory management and beyond. Both, complete modules, standard products and individual applications can thus be integrated straight through a cloud connection. The PaaS solution not only reduces the administrative effort noticeably; the integrated applications can also be easily scaled. By avoiding the need to purchase software and hardware, fixed costs are also significantly reduced. Finally, Edge.One may provide the digital anchor for future smart extensions, for example in the form of IIOT, augmented reality or blockchain applications.

Get in touch!

Would you like to know more about our solutions? Then please write us using the contact form. My colleagues and I look forward to exchanging ideas with you.

Dominik Weggler

Head of Sales Germanedge

We need your approval

To contact us via our form or to download content, you must accept our cookies.

Alternatively, you can send us an e-mail to info@germanedge.com.