Digital factory – definition, advantages, implementation

What is a digital factory – and what isn’it?

A digital factory is a dynamic network of digital models, methods and tools for planning, commissioning and operating a production facility. Far beyond just real-time logging and evaluating production data, it involves complete business processes, planning and management of production flows. This can only be done by combining all the data on design, resources, machines and systems, as well as the processes in this virtual representation of reality.

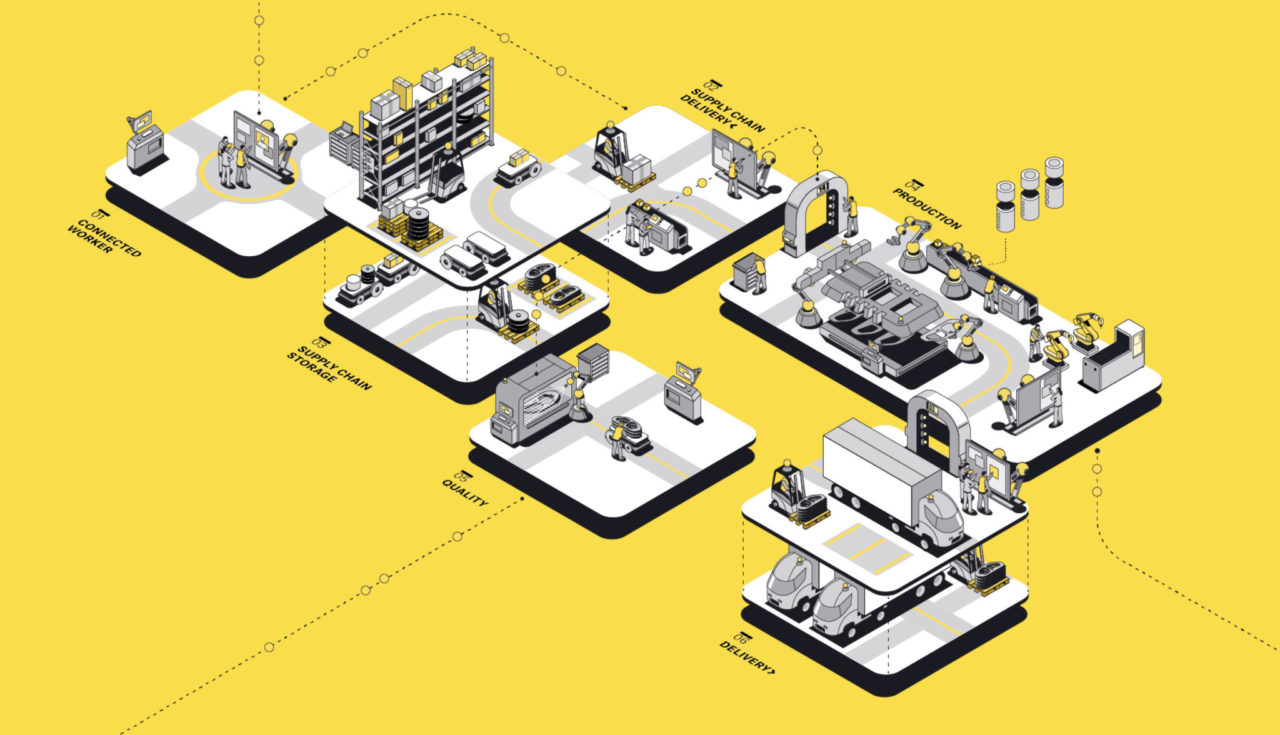

The virtual factory connects the shop floor and the top floor. It covers production and supply chain, factory operations and virtual planning. It is based on data and constantly changes according to requirements and new technology. There is more than just one road leading to the digital factory. It requires a flexible system based on a common data pool – a system that can be expanded and changed one step at a time.

Essential

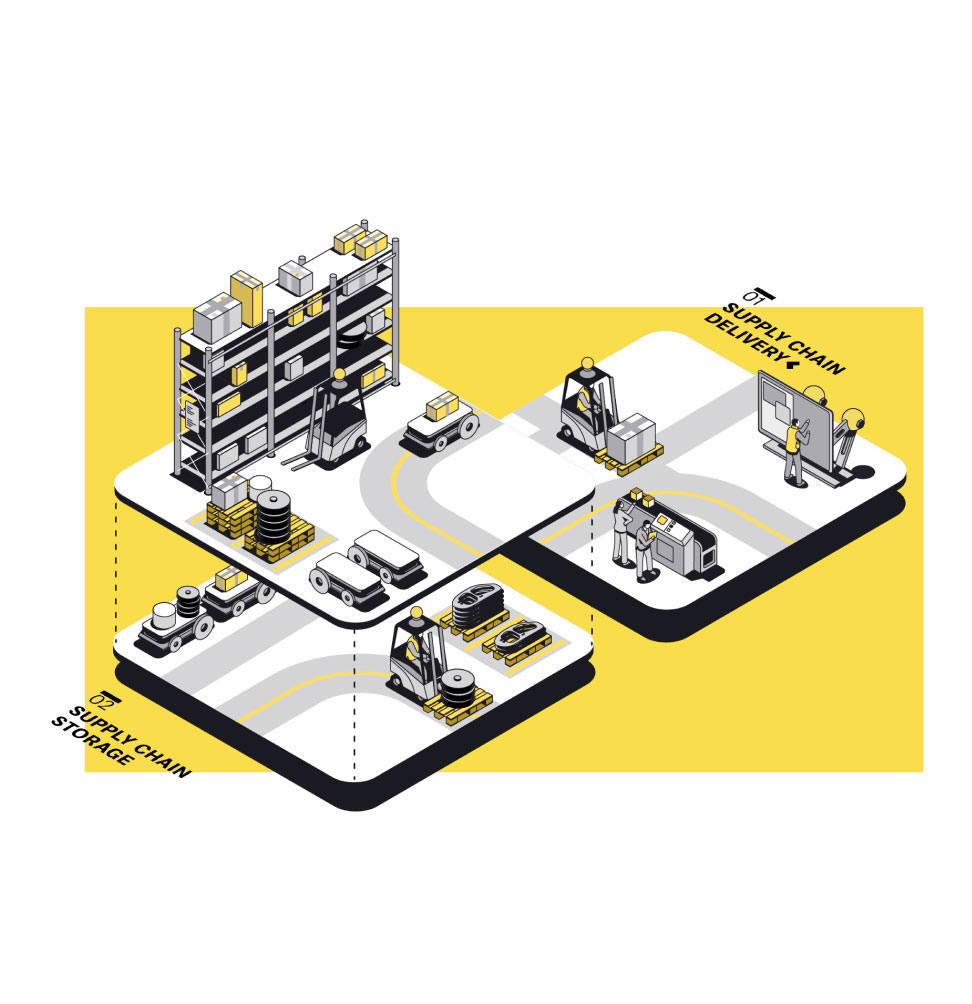

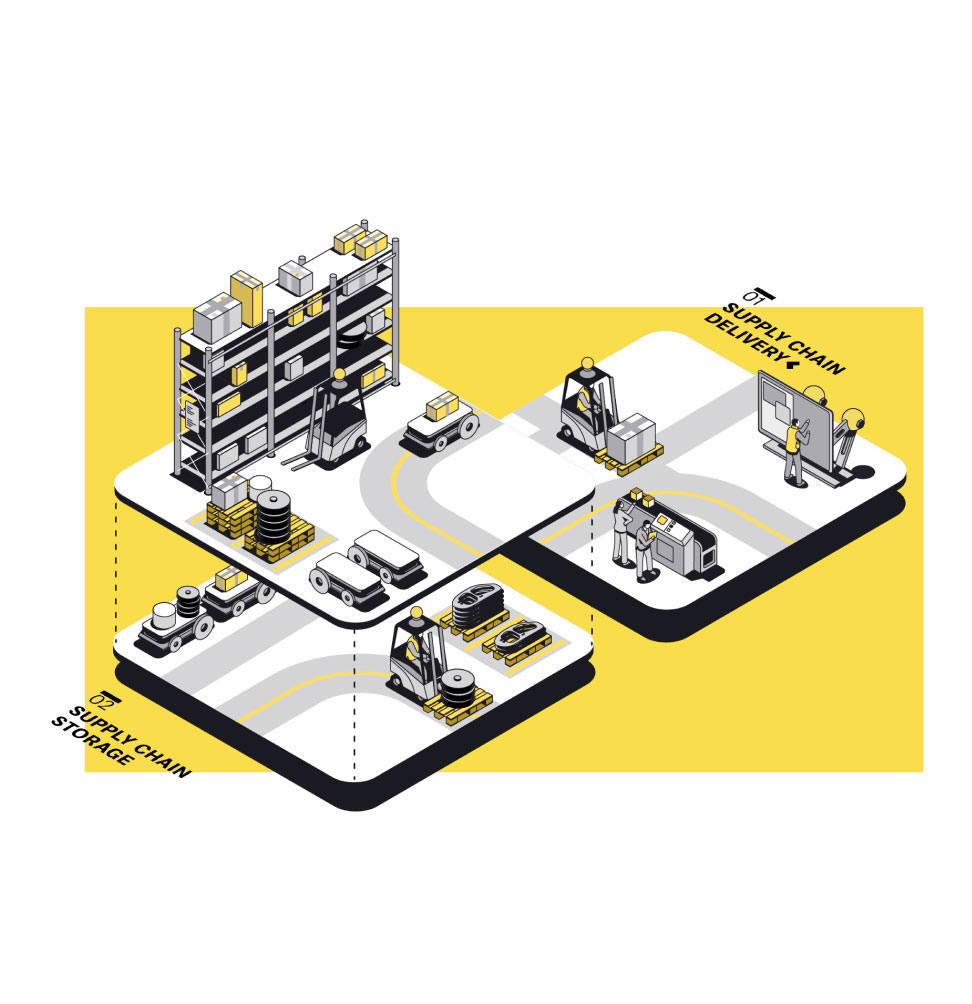

Free flow of data all the way to the supply chain

The digital factory breaks down silos: Systems and processes that evolved separately are connected to allow a free flow of data. The virtual factory ultimately extends far beyond production: it is open and reaches deep into the supply chain, thus enabling more detailed resource planning. It also extends into the demand chain, allowing for forward-looking production planning.

Optimal: Loose couplings for flexibility

This makes the digital factory the data hub of a manufacturing company, in which all relevant applications are loosely coupled, from the shop floor to the top floor. This loose coupling makes it easier to make changes to individual components without hindering the overall flow of information.

More than a digital twin

While a digital factory is more than just a digital twin or a smart factory, it is also inconceivable without them. The digital twin mirrors the industrial plants in virtual space. More: Physical production and its digital copy interact intensively with one another. Nevertheless, the digital twin remains limited to the actual factory – it usually does not include data from the business environment or the supply chain.

And more than a smart factory

A perfect digital twin results in the smart factory – an intelligent factory with machines that organise themselves. It is based on cyber-physical systems and intelligent networking of machines and products via the Internet of Things (IoT). Add the supply and demand chains and it becomes a digital factory.

This revolutionary method of production is also called Industry 4.0 (Industrial Internet in the United States) and refers to the fourth, digital industrial revolution.

Advantages of the digital factory

Virtual production provides the opportunity to build on an actual state and to think and work from there. You can digitise from one or more points and achieve maximum value from more and more data. For manufacturing companies, this means: more efficiency, quality, transparency and faster, more individualised production.

The digital factory can solve common problems: volatile demand, the trend towards batch size 1, high pressure on costs and delivery dates combined with difficult resource planning and unreliable supply chains. In the digital factory you can run through various scenarios, change individual components and framework conditions and examine consequences and benefits.

But even when their goals are similar, not all companies follow the same path or have the same level of development: Framework conditions and requirements differ as much as methods and tools.

The connected worker benefits

This means that employees can work with digital tools and interact with machines and data. The objective: faster and better decision-making. These connected workers have access to production data and can access relevant, customisable sources of knowledge in real time.

Workers have instructions on the next work steps on the shop floor and become increasingly efficient in combination with machines. Management keeps an eye on the entire production process. The prerequisite for this: sophisticated digital shop floor management for the worker level or an individual analysis dashboard with data from production and business management for plant management. Digital factories make people more competent and more important for production.

Unified production workplaces ensure flexibility

People, machines and back offices are completely integrated in the digital factory. From an employee perspective, this opens up a completely new set of opportunities. Real-time production and logistics data is collected and maximum transparency is created along the entire value chain. More: data and data evaluation are tailored to the needs of individual employees and are available to them on a mobile basis and in real time.

The aim of this Unified Production Workplace (UPW) is to make it easier for employees at all levels to do their jobs. It creates a framework for faster and better decision-making. Short-term changes to general conditions such as customer requirements, raw material offers or machine availability also flow into the data. The system creates a significantly higher degree of flexibility – batch size 1 is within reach without increasing pressure on the shop floor.

The road to the digital factory – from digitalised islands to completely transparent production

In many companies, completely virtual production is at best in the planning stage. A comprehensive strategic approach or the perfect simulation of the physical network of machines is more of an exception than a rule. Optimising production operations as continuously as possible and in real time requires a future-proof and adaptable production network.

The most important prerequisite for this is networking and end-to-end data use. The focus here should always be on the long-term goal of the virtual factory: extensive automation based on comprehensive data. This requires not only that all machines, tools and products communicate with one another, but also that the production level is coupled with the business level – compliant with ISA95. The easiest way to implement this is with a dedicated information layer.

This is what the digital factory consists of

We offer many of these solutions ourselves – first and foremost Edge.One. With this Platform as a Service (PaaS) solution designed for manufacturing, you can reap all the benefits of the cloud, automation and IIoT. Edge.One makes virtual production and collaboration across production disciplines possible.

But that alone won’t help you navigate your way through the myriad of digital models and instruments. How do you create a digital image of your production in which all data flow together? Where do you start? How do you incorporate what’s already there?

Learn how to develop a comprehensive strategy here

Product Bundles

Get in touch!

Would you like to know more about our solutions? Then please write us using the contact form. My colleagues and I look forward to exchanging ideas with you.

Dominik Weggler

Head of Sales Germanedge